Vacuum electron beam welding method for special-shaped thin-walled metal plate welding structure cabin

A vacuum electron beam and electron beam welding technology, which is applied in the field of material welding, can solve problems such as difficult to ensure weld quality, small structural rigidity, and large welding deformation, so as to avoid electron beam cutting effect, reduce assembly requirements, and improve weld seam Shaped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the present invention in detail with reference to the drawings and embodiments:

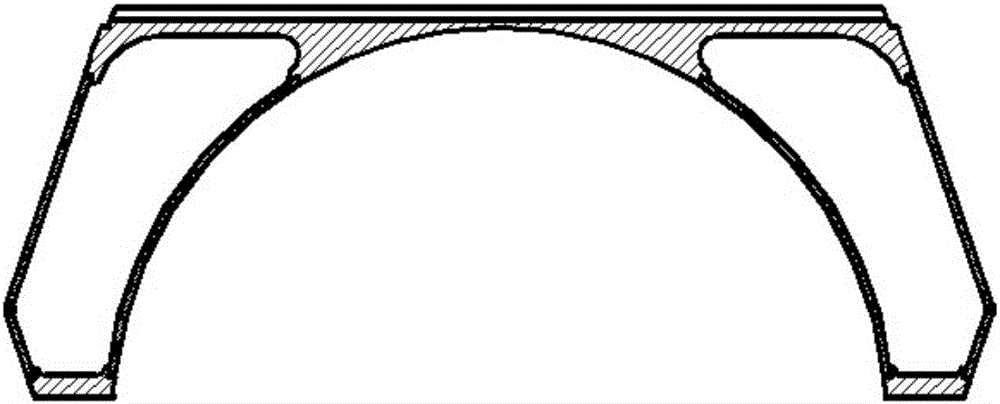

[0021] A vacuum electron beam welding method for a special-shaped thin-walled sheet welding structure cabin, which includes the following steps:

[0022] Step 1: Preparation before welding;

[0023] Step 2: Welding and assembly;

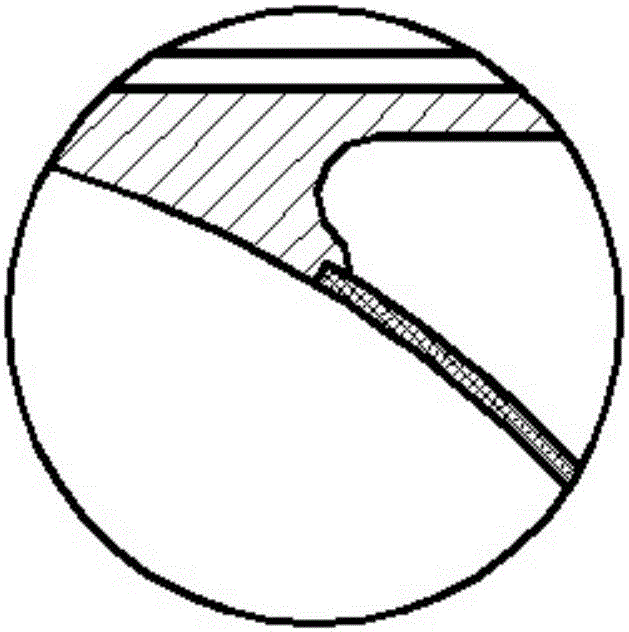

[0024] Step 3: Electron beam welding;

[0025] Step 4: Quality inspection after welding.

[0026] The described step 1: pickling the tank section to be welded to remove the surface oil and oxide film, drying at 50-80°C for 20-30 minutes, after completion, use a wire brush to polish the welded area to a bright metallic luster. And wipe it clean with acetone.

[0027] The described step 2: Use welding tooling to assemble the section to be welded to ensure that the assembly position is correct, the gap between the surfaces to be welded is not greater than 0.2mm, and the amount of misalignment is not greater than 0.2mm. After the assembly is completed, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com