Tank of benzene hydrogenation engineering and manufacturing and mounting method thereof

A production method, benzene hydrogenation technology, applied in the field of tanks, can solve the problems of high production costs, inconvenient production and installation methods, unscientific production and installation of tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

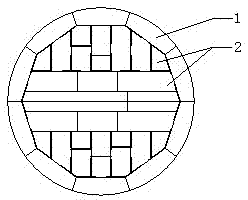

[0132] The tank of the benzene hydrogenation project of the present invention is a vertical cylindrical steel storage tank. see now Figure 19 with Figure 20 , Figure 19 It is a schematic diagram of the tank structure of the embodiment of the present invention, Figure 20 for Figure 19 top view. As shown in the figure, the vertical cylindrical steel storage tank is provided with a tank vault, and a breather valve 24 and a light transmission hole 26 are arranged on the tank vault; several short pipes 28 are arranged on the tank of the vertical cylindrical steel storage tank. The vault and the tank wall are used to communicate with various media; the wind-resistant ring 30, the heat preservation ring 31 and a coil ladder 32 are arranged around the tank wall;

[0133] The waveguide 25 is a circular tube type radar waveguide, the waveguide extends from the top of the tank to the bottom, and the top of the waveguide is equipped with a flange for installing a radar level gau...

Embodiment 2

[0136] The tank manufacturing method of the benzene hydrogenation project of the present invention is characterized in that comprising the following steps:

[0137] a. Tank prefabrication

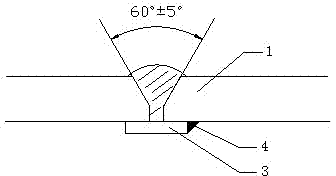

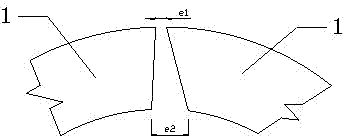

[0138] In construction and production, many components and materials of the tank must be prefabricated before installation, such as tank bottom edge plate forming, tank wall bevel and arc processing, and various arc components (reinforcing rings, etc.). Some components also need to be prefabricated on a special platform in order to form specifications, reduce high-altitude operations, improve work efficiency, and ensure project quality.

[0139] The chord length of the arc-shaped sample plate used for storage tank construction shall not be less than 2m, the length of the straight-line sample plate shall not be less than 1m, and the chord length of the arc-shaped sample plate used for measuring weld corner deformation shall not be less than 1m.

[0140] The prefabricated cutting of tank bot...

Embodiment 3

[0190] A tank installation method for a benzene hydrogenation project, characterized in that it comprises the following steps:

[0191] Figure 18 It is a block diagram of the tank installation and construction process of the benzene hydrogenation project of the embodiment of the present invention.

[0192] a. Floor laying and welding, including the following steps:

[0193] (1) Re-examine the foundation of the storage tank. According to the orientation of the plan, draw two centerlines perpendicular to each other on the foundation of the storage tank, and pay attention not to damage the foundation during the installation of the storage tank. If there is any damage, it must be repaired;

[0194] (2) The lower surface of the bottom plate shall be derusted according to the requirements of the drawing, and the first coat of epoxy coal tar pitch paint shall be painted immediately after passing the joint inspection by the supervision of Party A, and the edge of each plate shall no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com