Resistance welding equipment and welding control method

A resistance welding and control method technology, applied in resistance welding equipment, welding equipment, welding monitoring devices, etc., can solve problems such as unstable welding quality, achieve the effects of improving quality and stability, ensuring quality, and high visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1, using resistance welding equipment to weld the wiper motor gear cover

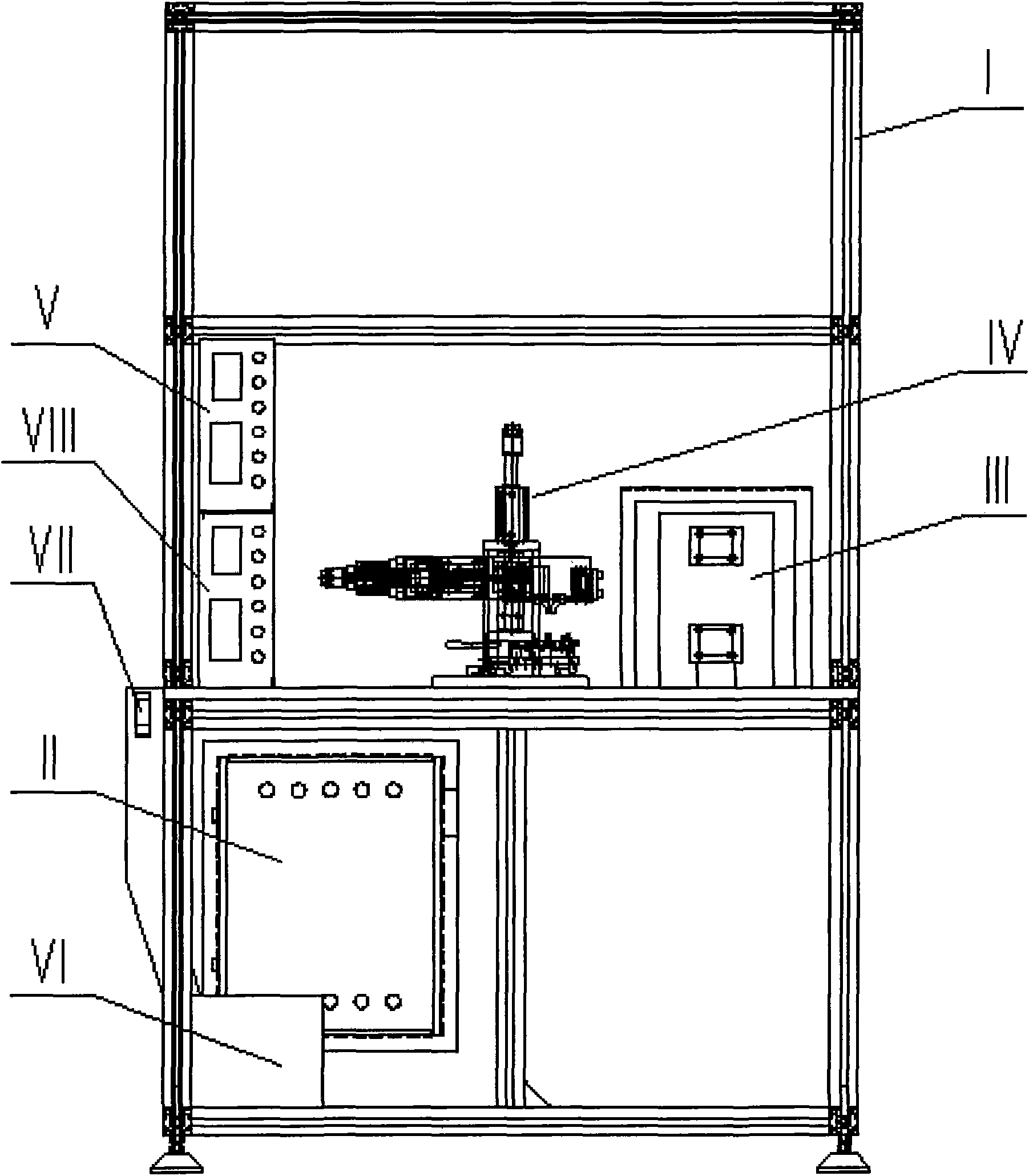

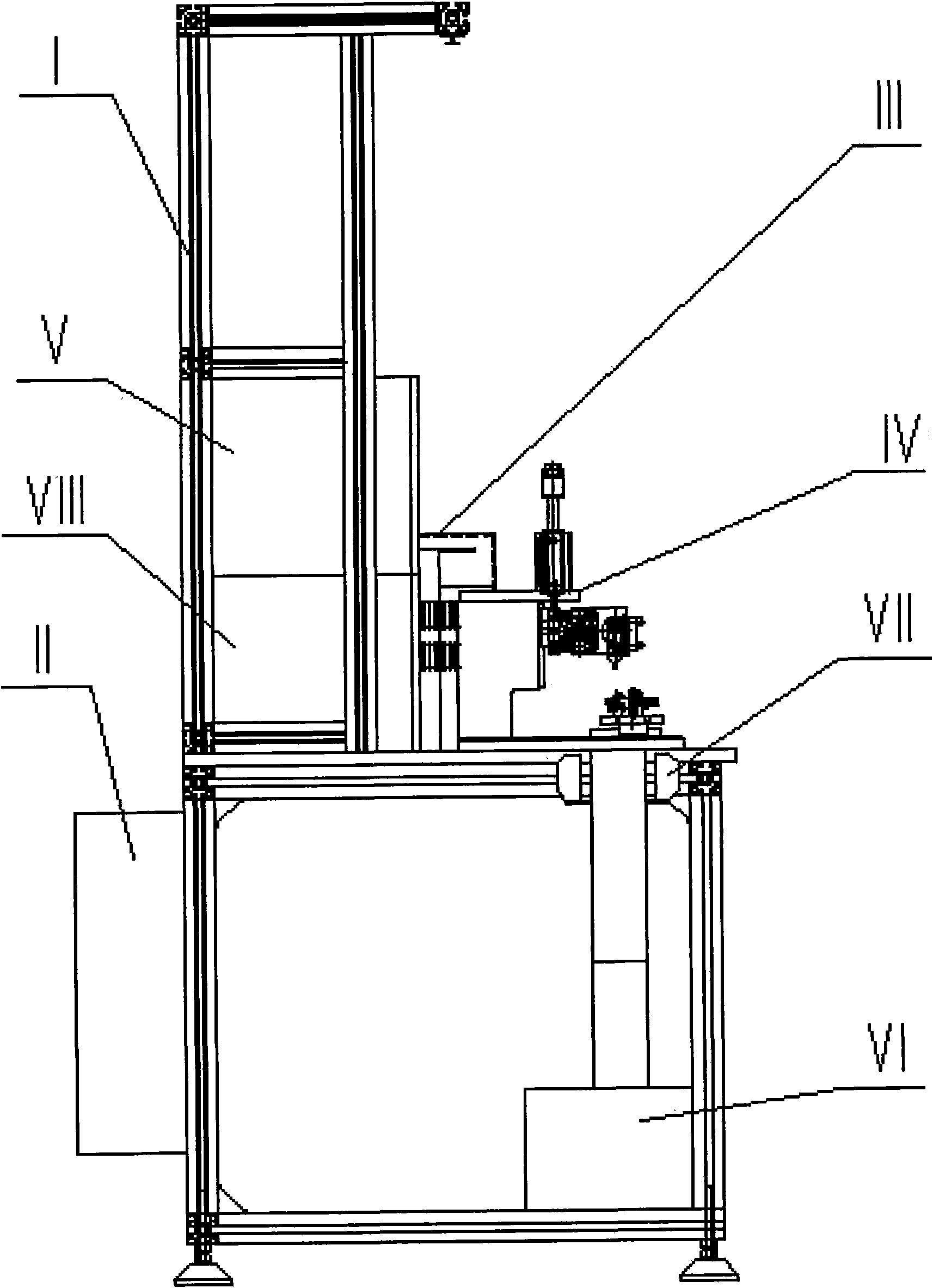

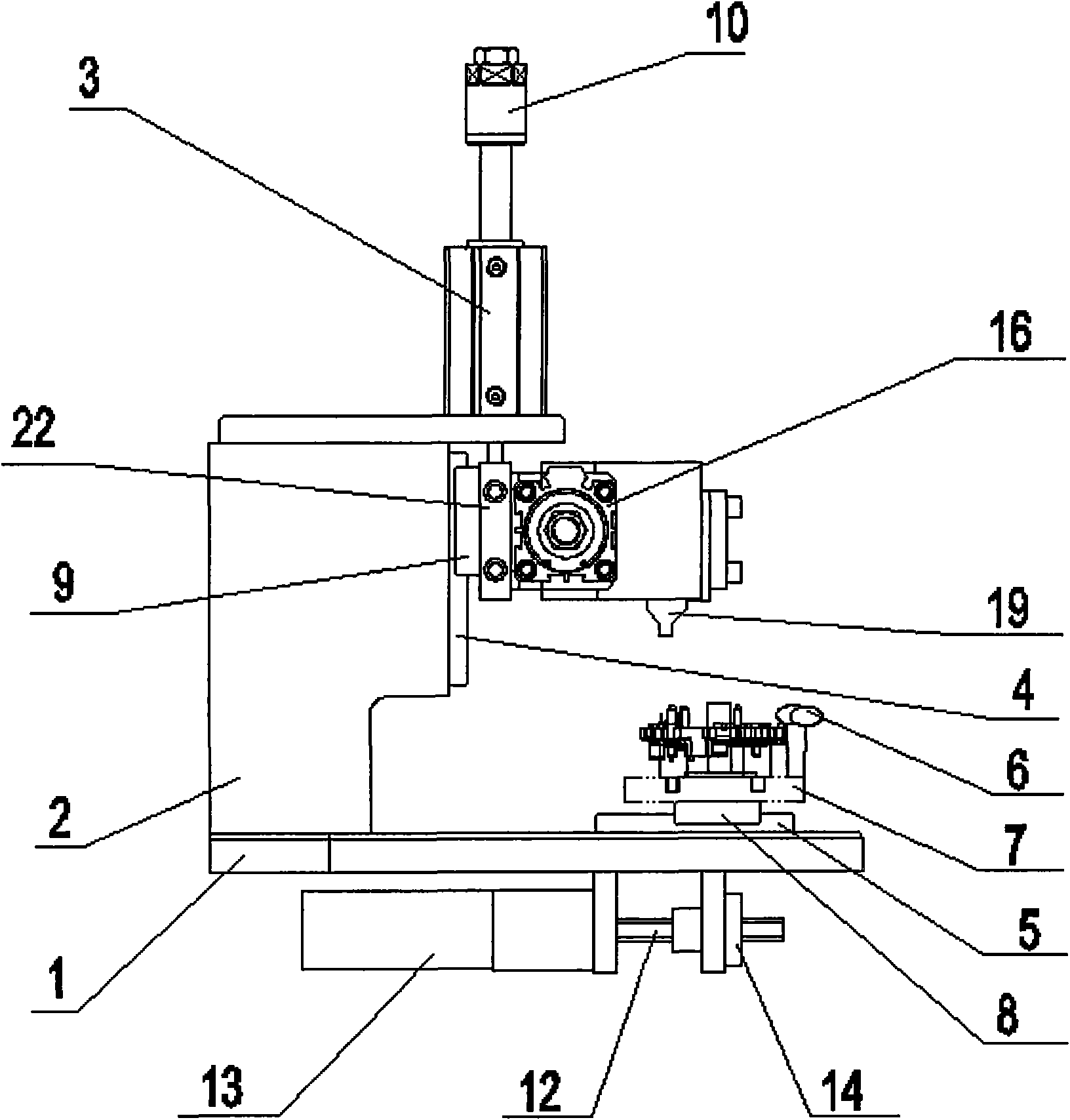

[0021] The resistance welding equipment with the structure of the invention is used to weld the metal insert and the metal spring piece on the gear cover of the automobile windshield wiper system. Referring to the accompanying drawings, the resistance welding equipment is composed of a frame I, an electric control box and a PLC system II, a welding transformer III, an action mechanism IV, a welding machine controller V, a waste box VI, an optical fiber sensor VII and a sensor controller VIII. The box and PLC system II are located at the lower part of the frame I, the welding transformer III is located at the right side of the middle workbench of the frame I, the welding machine controller V and the sensor controller VIII are located at the left side of the middle workbench of the frame I, and the waste box VI One foot is located at the bottom of the frame I, the optical fiber sensor VII i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com