Q460 steel thick plate welding process

A welding process and workpiece technology, applied in the field of welding process of Q460 steel thick plate, can solve the problems of high requirements for preheating and interlayer temperature control, easy to produce welding cracks, large hardening tendency, etc., and achieve good mechanical properties of the workpiece, The effect of small welding residual stress and small heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0030] The invention proposes a welding process for Q460 steel thick plates.

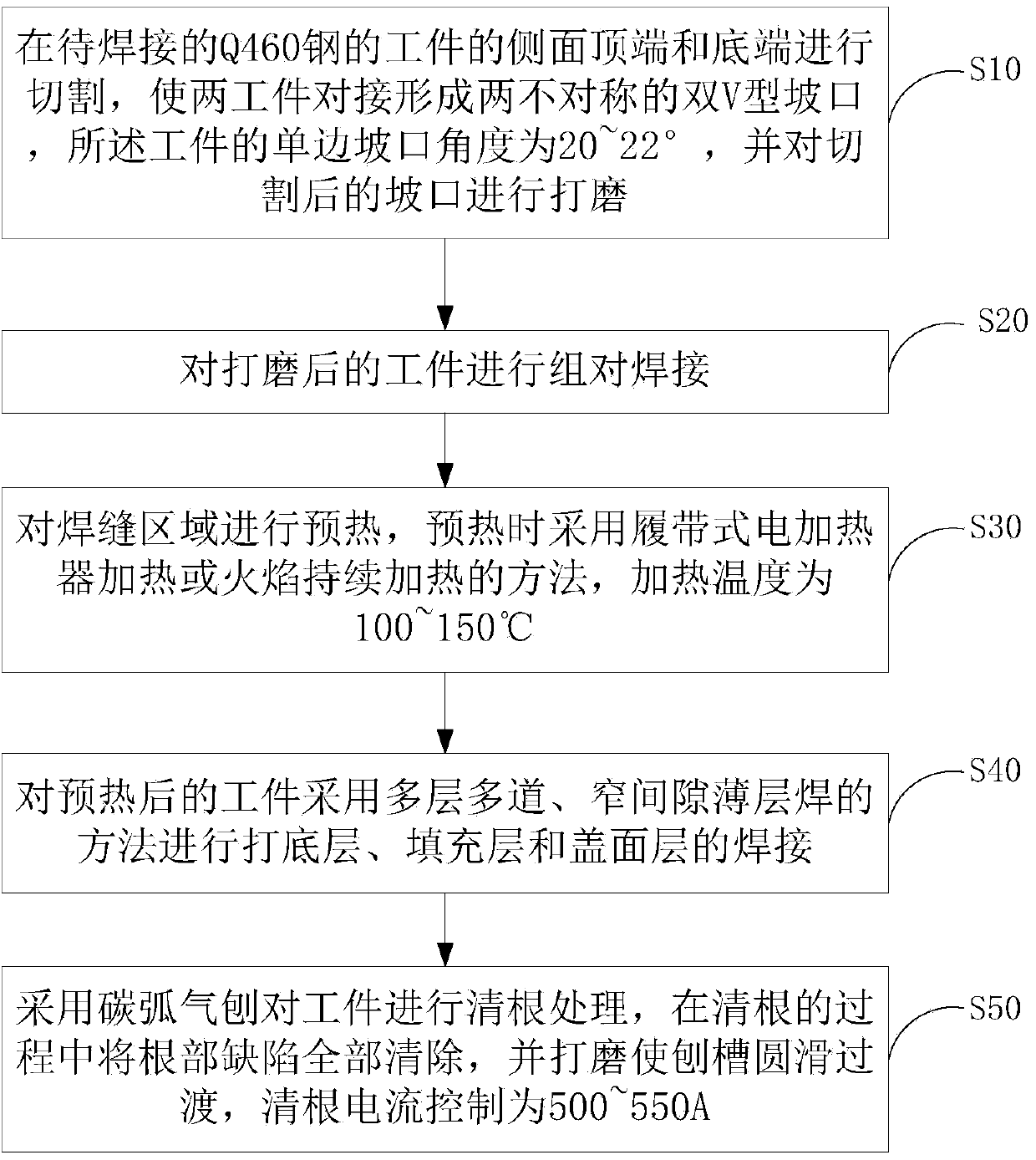

[0031] refer to figure 1 , figure 1 It is a schematic flow chart of a preferred embodiment of the welding process of Q460 steel thick plate in the present invention.

[0032] In this preferred embodiment, a welding process of Q460 steel thick plate comprises the following steps:

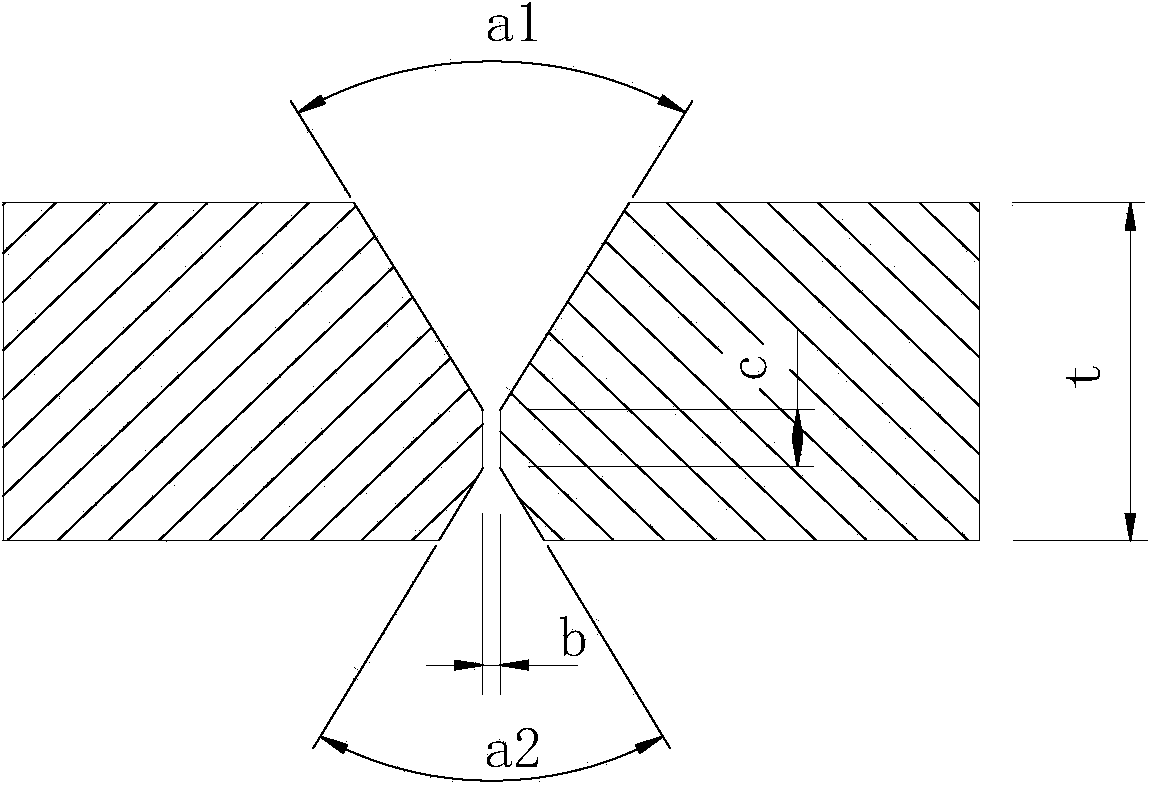

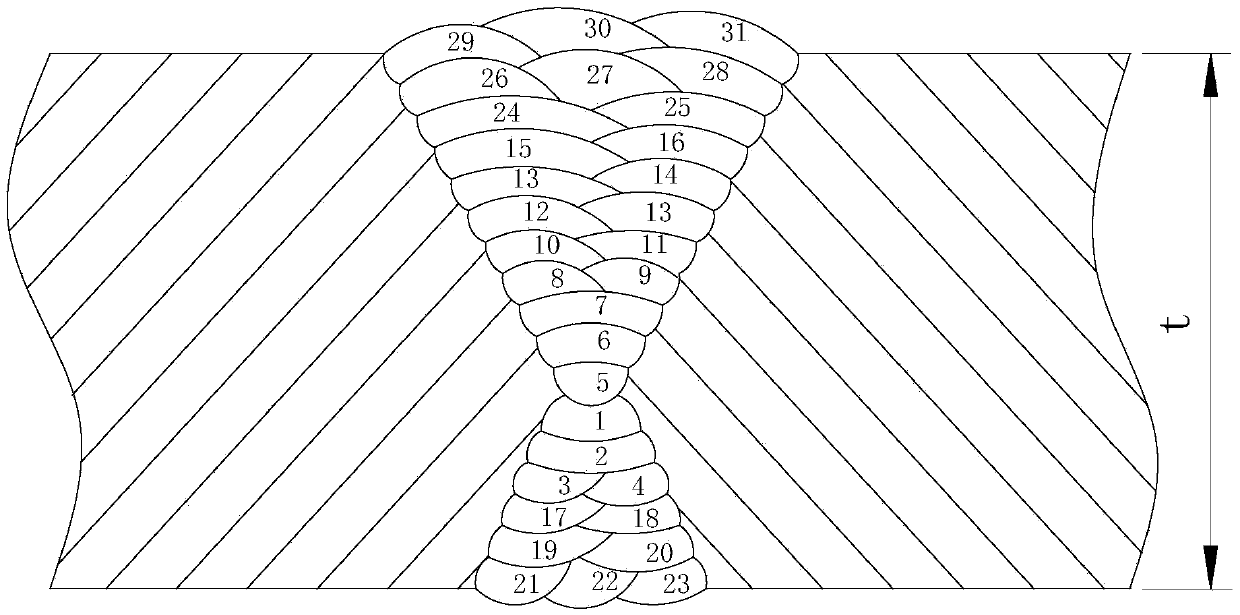

[0033] Step S10, cutting the top and bottom ends of the side surfaces of the Q460 steel workpieces to be welded, so that the paired two workpieces are butted to form two asymmetrical double V-shaped grooves [when the workpieces are pair-welded (that is, two to-be-welded Welded Q460 steel workpieces are aligned) to form asymmetric double V-shaped grooves], the single-side groove angle of the workpiece is 20~22°, and the cut grooves are polished;

[0034] Step S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com