Assembling precision control method of single-body blades in blisk of electron beam welding structure

An electron beam welding and integral blisk technology, applied in the field of machining, can solve the problems of high precision requirements, difficult processing, complex structure, etc., and achieve the effects of controlling post-weld precision, reducing development cycle, and improving assembly precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

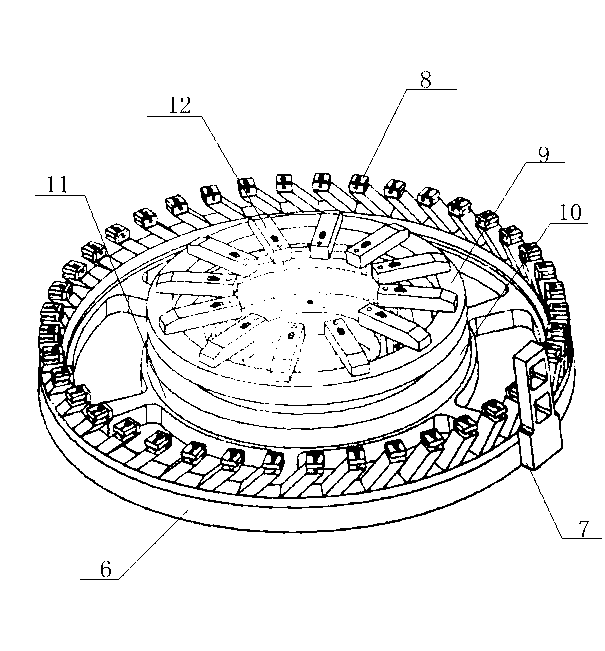

[0028] The technical scheme that realizes the object of the present invention is described further below in conjunction with accompanying drawing of description:

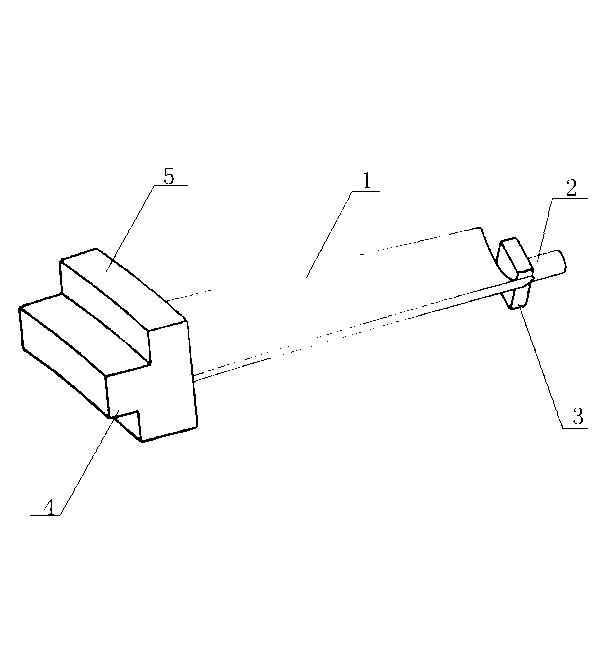

[0029] (1) Processing single blades with welded structure: select precision forging blanks to process blade blanks, input the three-dimensional space data of precision forging blanks into the computer, establish a three-dimensional data model of blade blanks in the computer, and design a as attached figure 1 The protruding process round table 2 shown, and the center of the process round table 2 coincides with the blade stacking axis, and a reinforced connection square platform 3 is added between the process circle 2 and the tip of the blade, and the upper part of the connection square table 3 is designed as a round table shape , the lower part remains in blank state;

[0030] Forge the blade blank according to the above-mentioned design structure model, adopt five-coordinate milling and add the center, take the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com