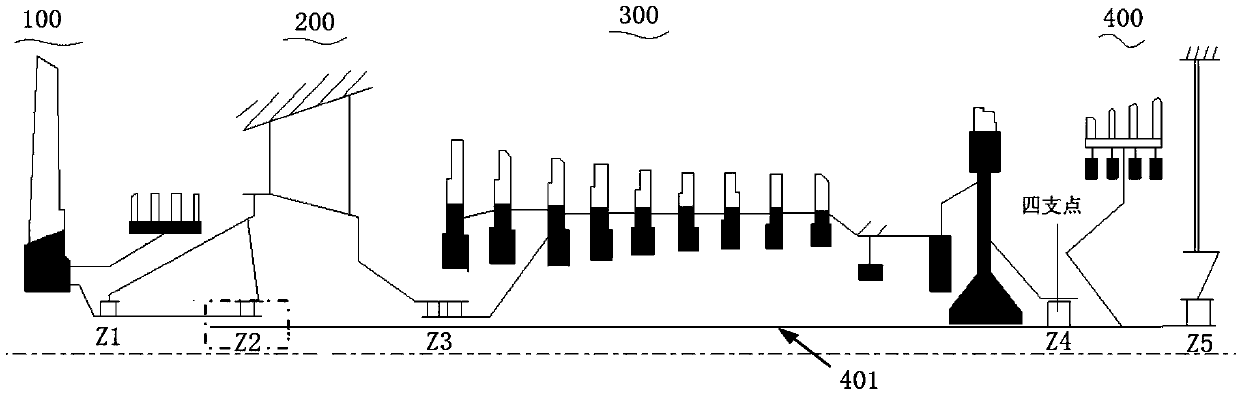

Aviation engine low-pressure turbine installation device

A technology for aero-engines and low-pressure turbines, applied in aircraft parts, transportation and packaging, metal processing, etc., can solve the problems of reduced bearing life, accelerated wear, and smaller diameter of rollers, so as to improve installation quality, reduce bearing damage, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

[0015] In order to solve the problem of damage to the four fulcrum bearings and reduce the service life of the bearings caused by the current installation method of the low-pressure turbine of the aero-engine, the application provides an installation device for the low-pressure turbine of the aero-engine that can effectively reduce the damage to the bearing during the installation process.

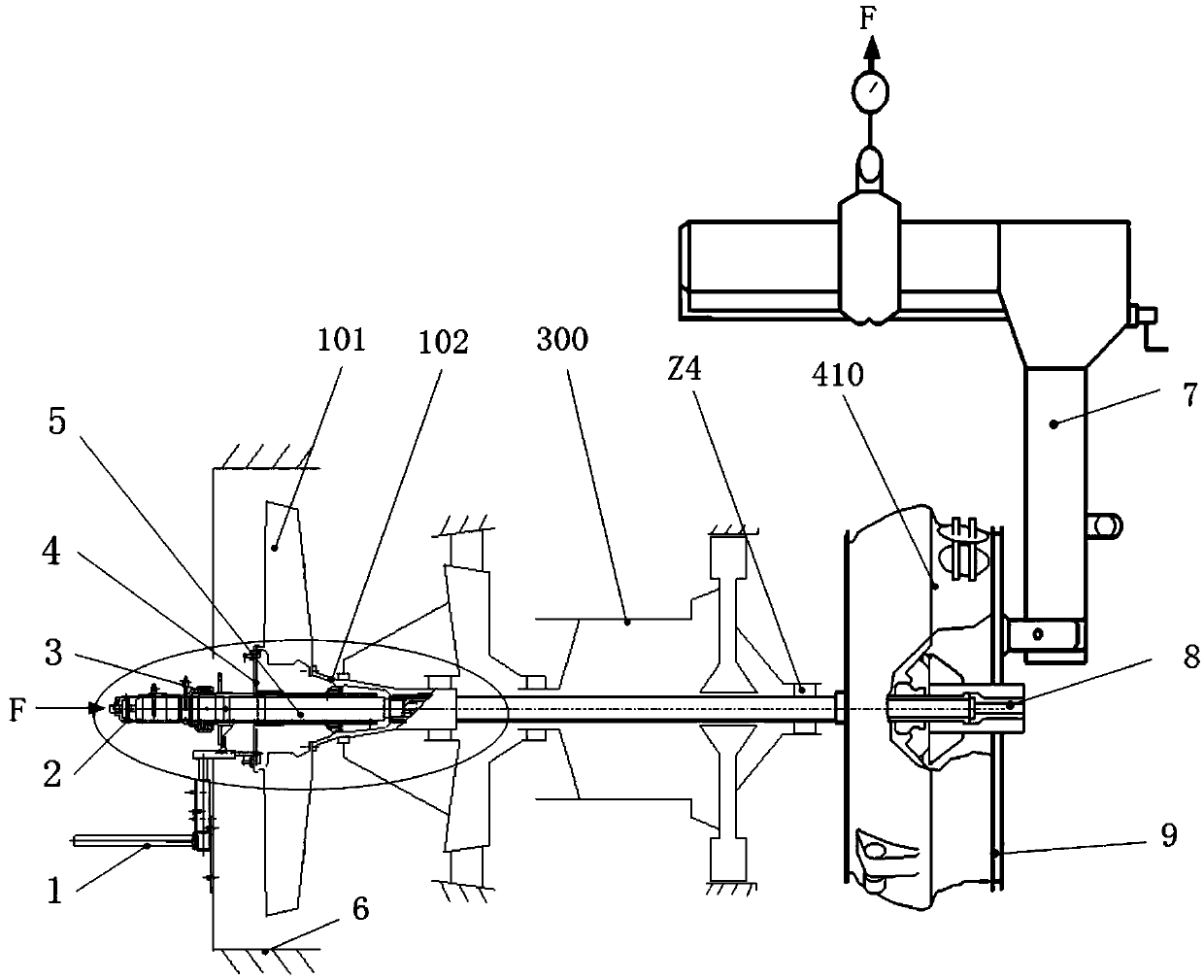

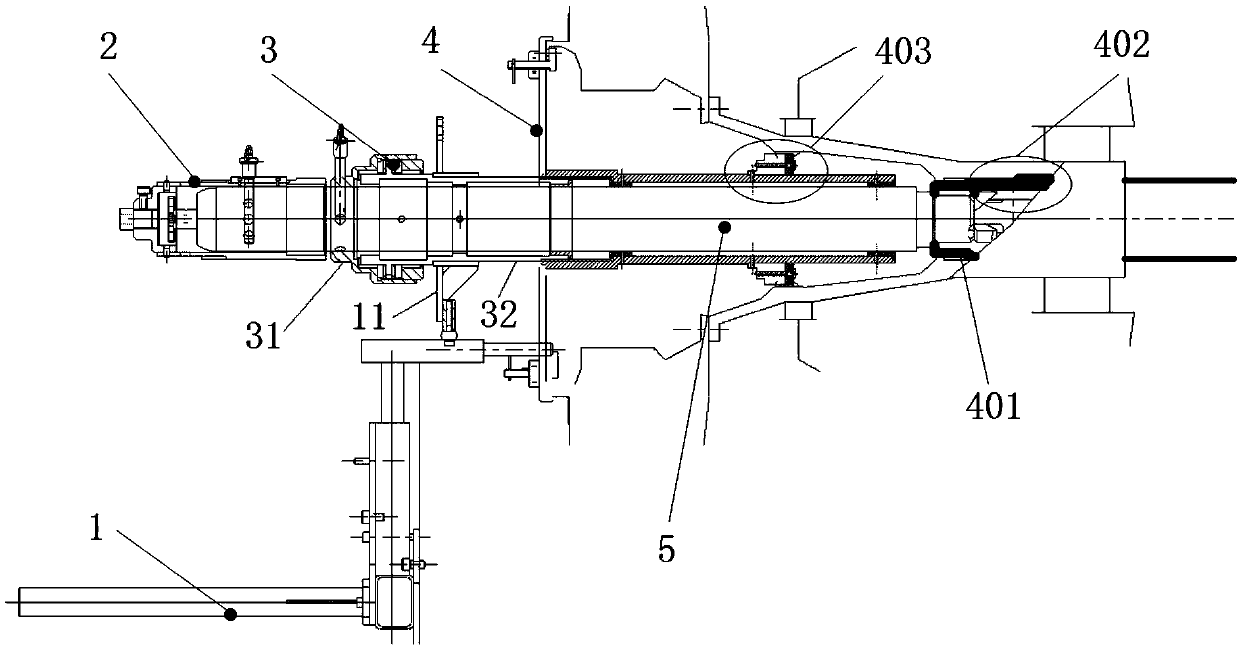

[0016] Figure 2 to Figure 4 As shown, the installation and rotation of the low-pressure turbine is realized by the low-pressure turbine installation device of the aero-engine of the present application, and is realized simultaneously with a crane and a torque wrench.

[0017] The aeroengine low-pressure turbine mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com