Plate dry-hanging and mounting robot

A robot and dry hanging technology, applied in the direction of lifting devices, buildings, building structures, etc., can solve the problems of high labor intensity of workers, slow construction speed, poor safety, etc., to optimize the construction environment, improve construction safety, and improve installation. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in combination with the embodiments and accompanying drawings, the specific implementation, structure, features and effects provided by the panel dry-hanging process installation robot of the present invention are described in detail as follows:

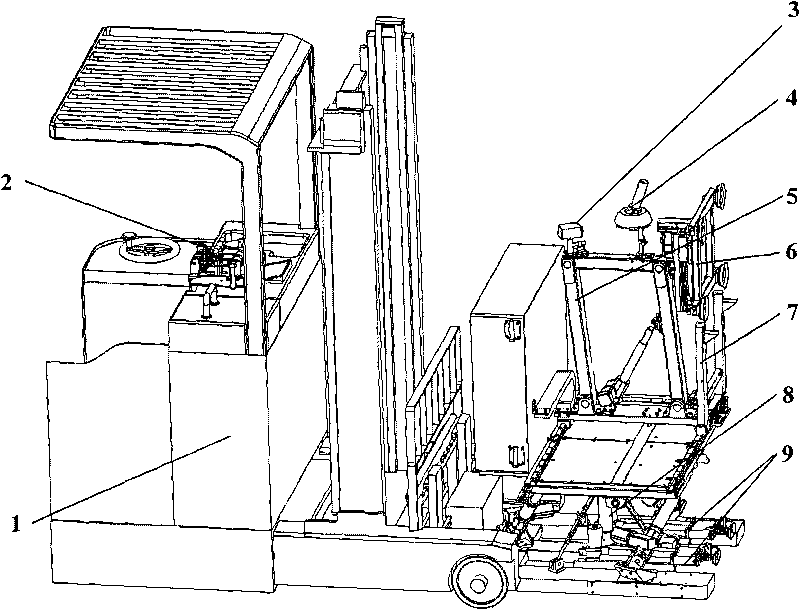

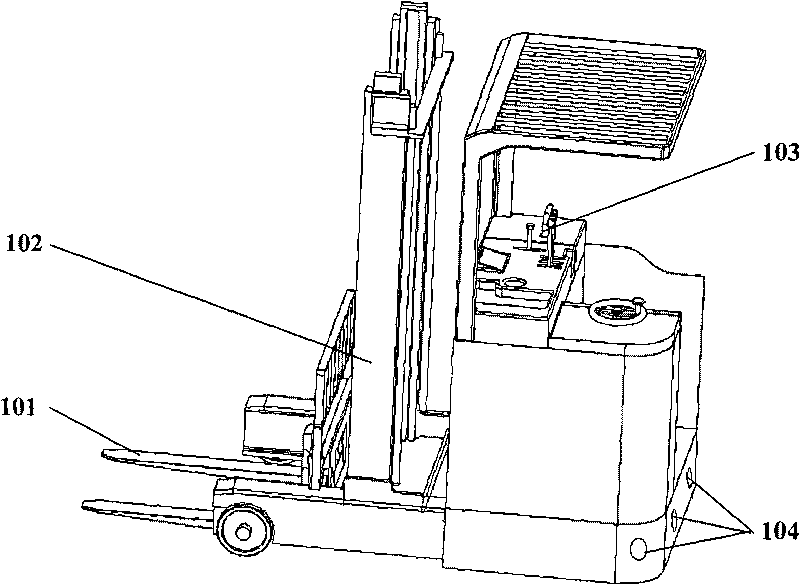

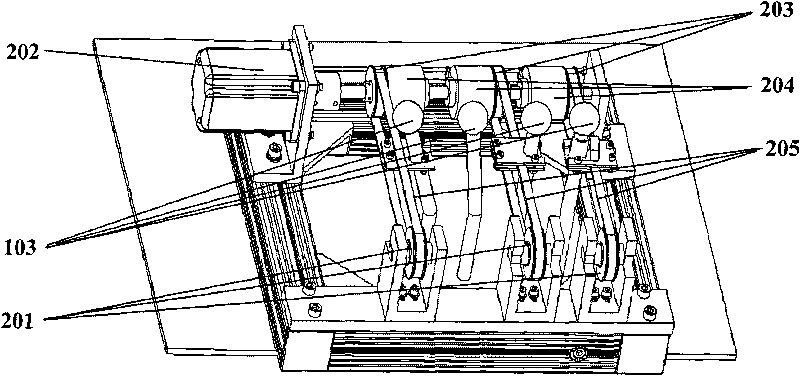

[0021] Plate dry-hanging technology installation robot (being called for short installation robot, see Figure 1-8 ), adopts a modular structure, including a mobile body module, an installation operation module, a vision-guided installation positioning system module and a motion control system module. The various modules are combined or used together in practical applications to effectively realize the purpose of panel automation and mechanized installation.

[0022] The mobile body module of the present invention mainly enables the installation robot to walk freely on the indoor rough cement floor and move flexibly in the operation space, and can lift the installation operation module (installation manipulator) to a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com