Welding deformation flatness correction method of finished steel crane beam

A welding deformation and flatness technology, applied in the field of welding, can solve problems such as long time-consuming, affecting installation progress and project quality, and high labor intensity of workers, so as to improve efficiency, reduce installation cost, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method for correcting the flatness of the welding deformation of the finished steel crane beam of the present invention comprises the following steps:

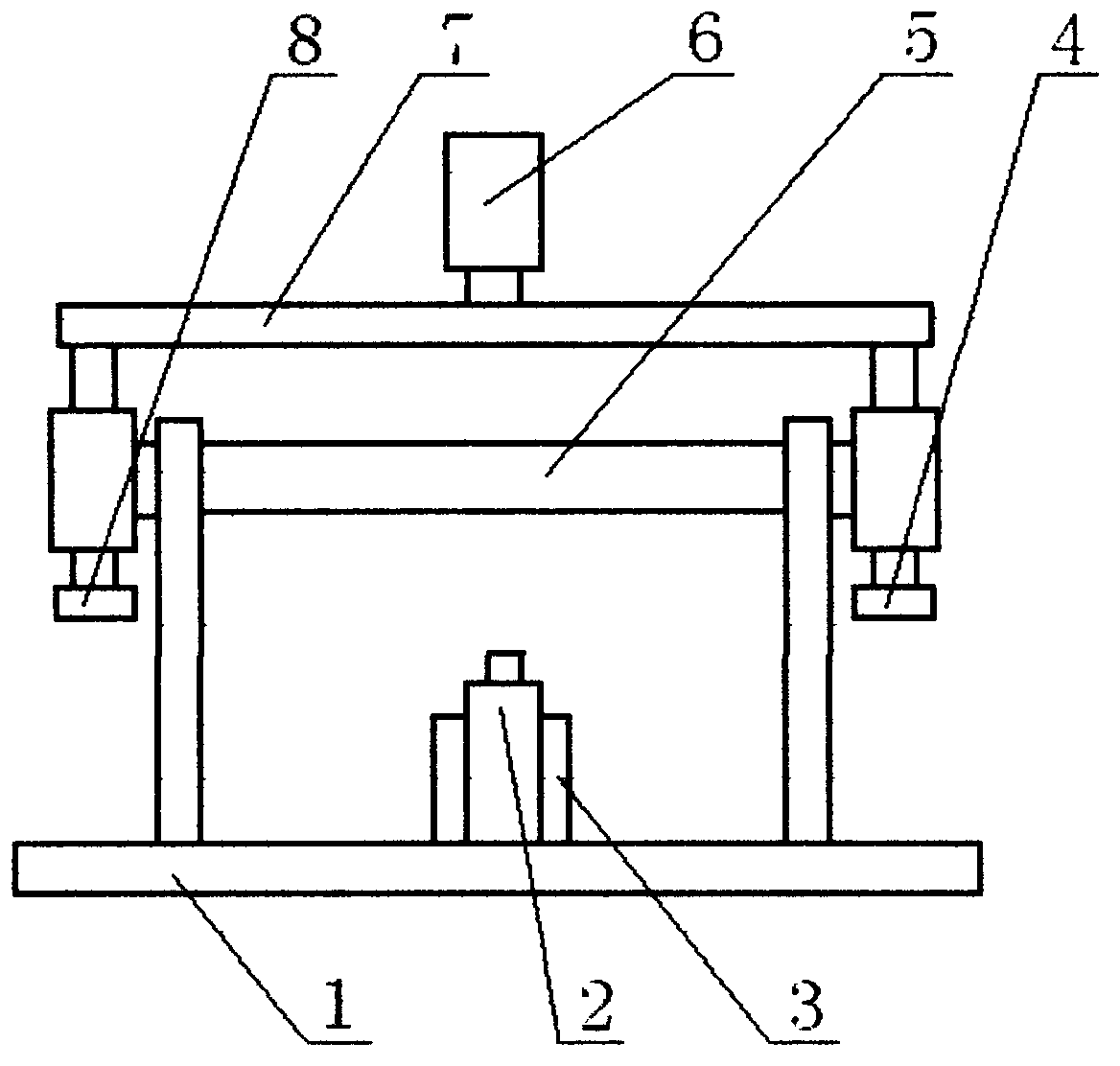

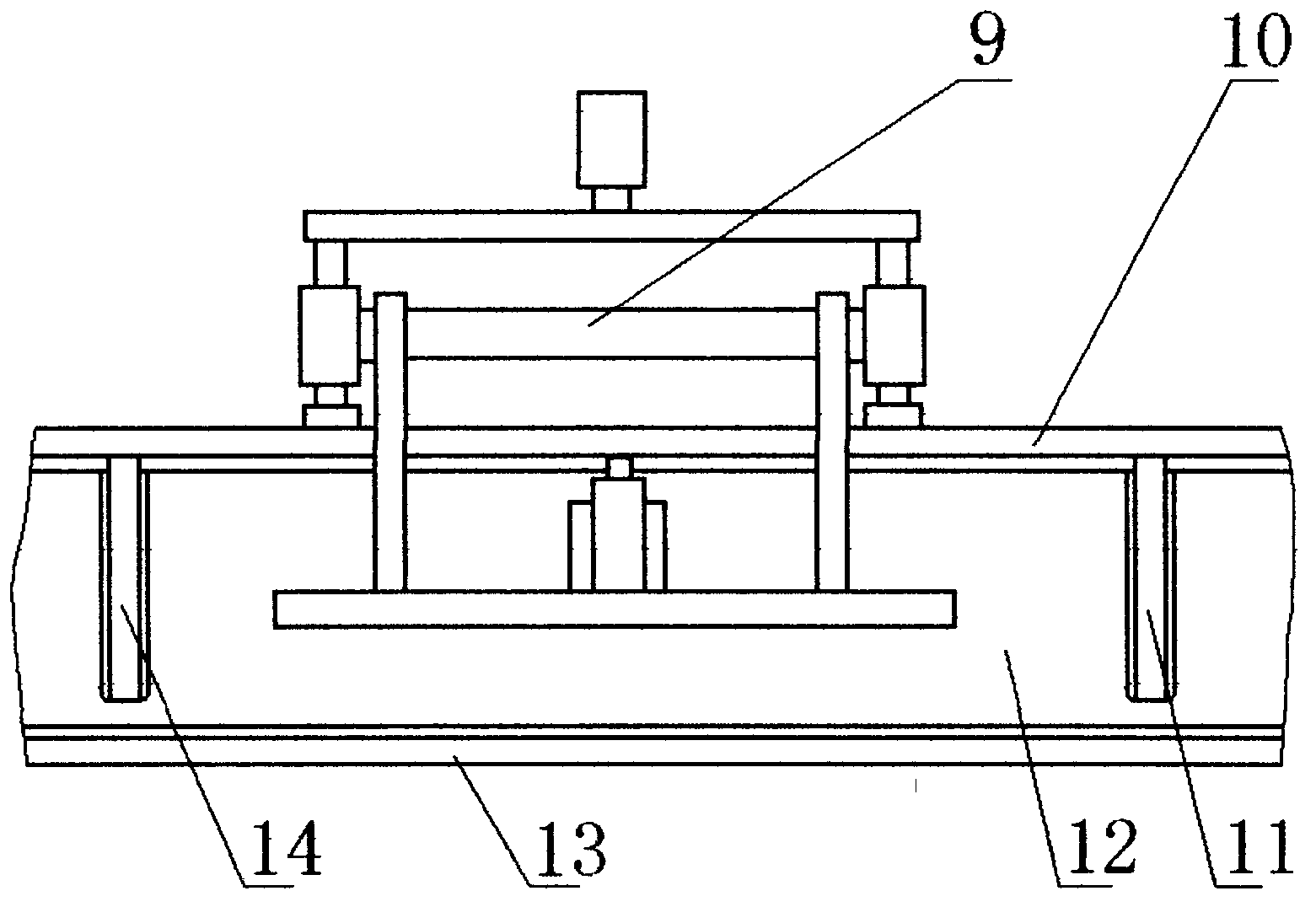

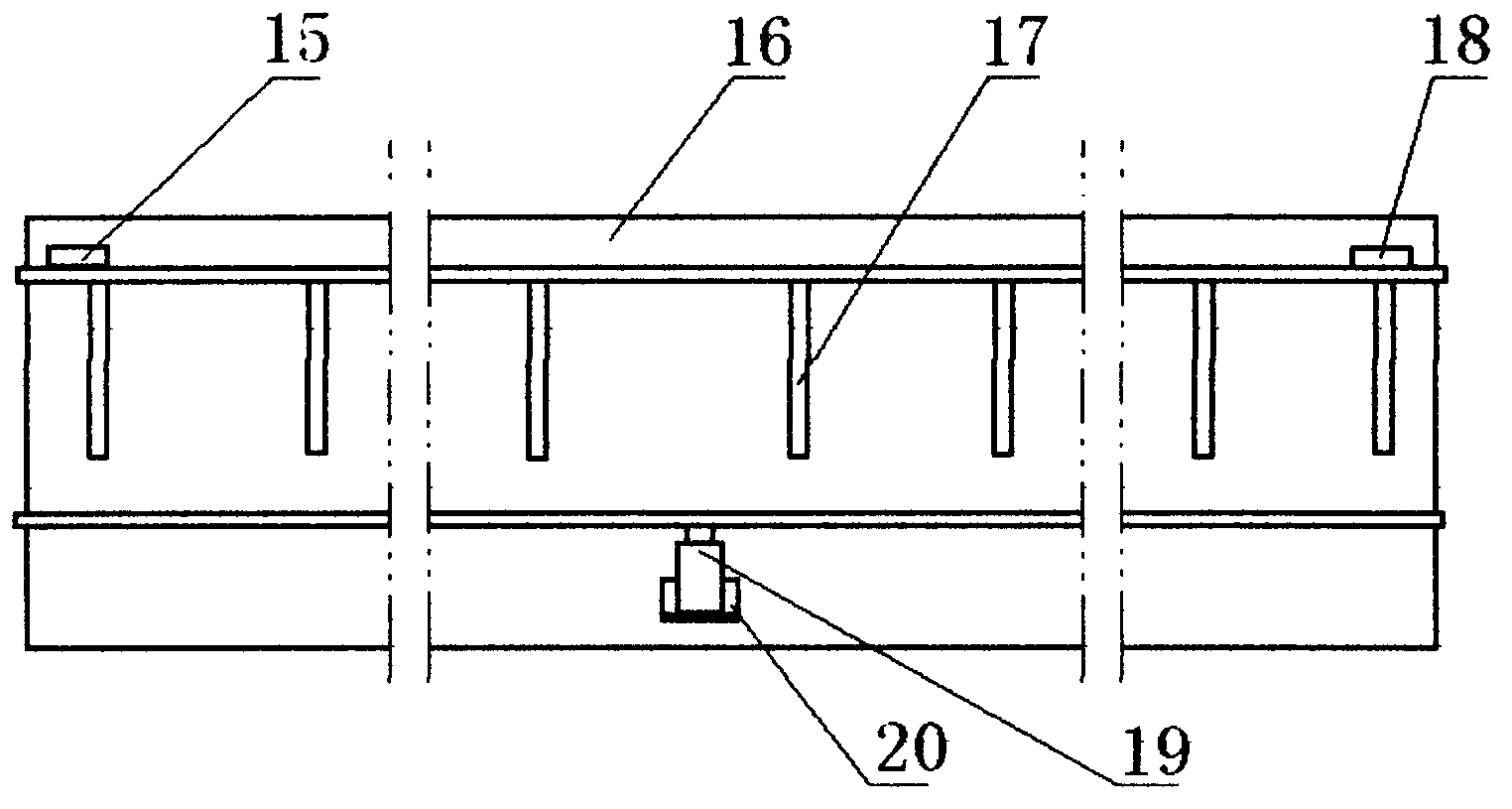

[0017] a. Make arc correction tooling and deflection control tooling, such as figure 1 , figure 2 , image 3 As shown, the arc correction tooling includes a bottom plate 1, an arc correction jack 2, a jack fixing frame 3, a curved arc correction bracket 5 and a pressing mechanism, the bottom plate 1 is located at the lower part of the curved arc correction bracket 5, and the jack fixing frame 3 is fixedly connected to On the base plate 1, the upper part of the arc-correcting bracket 5 is provided with a pressing mechanism. The pressing mechanism includes a cylinder 6, a cylinder connecting plate 7, a first pressing part 4 and a second pressing part 8. The two ends of the cylinder connecting plate 7 have a first pressing part 4 and a second pressing part 8, and the cylinder is connected The plate 7 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com