Hanging method of special-shaped reinforced concrete prefabricated column

A technology of reinforced concrete and hoisting method, which is applied in the processing of building materials, construction, building construction, etc., which can solve the problems of damage to the edges and corners of components, failure to guarantee the verticality of hoisting, and slippage of hoisting points, so as to avoid cracks and reduce labor costs. Positioning and correction time, avoiding the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

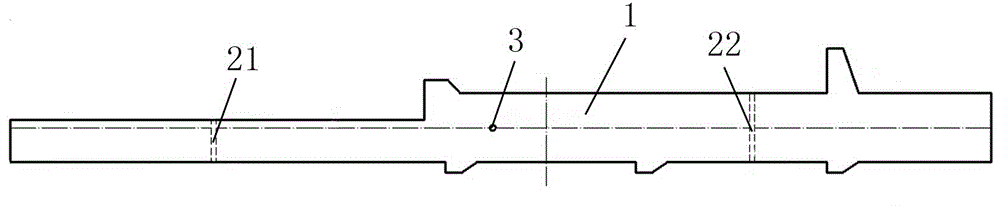

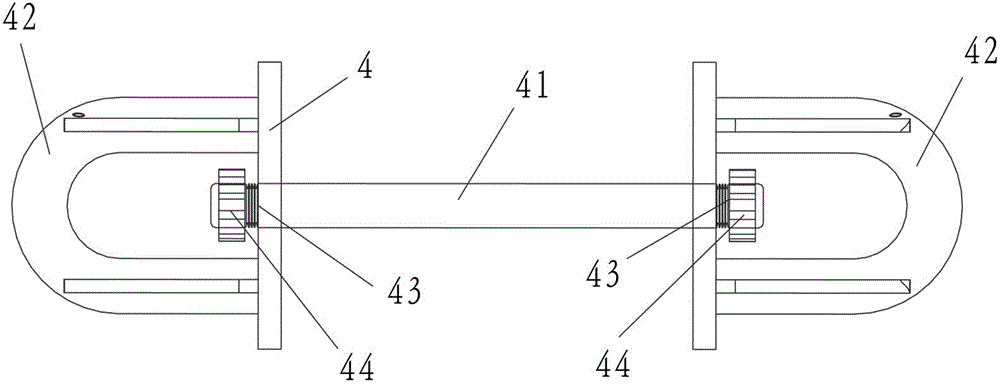

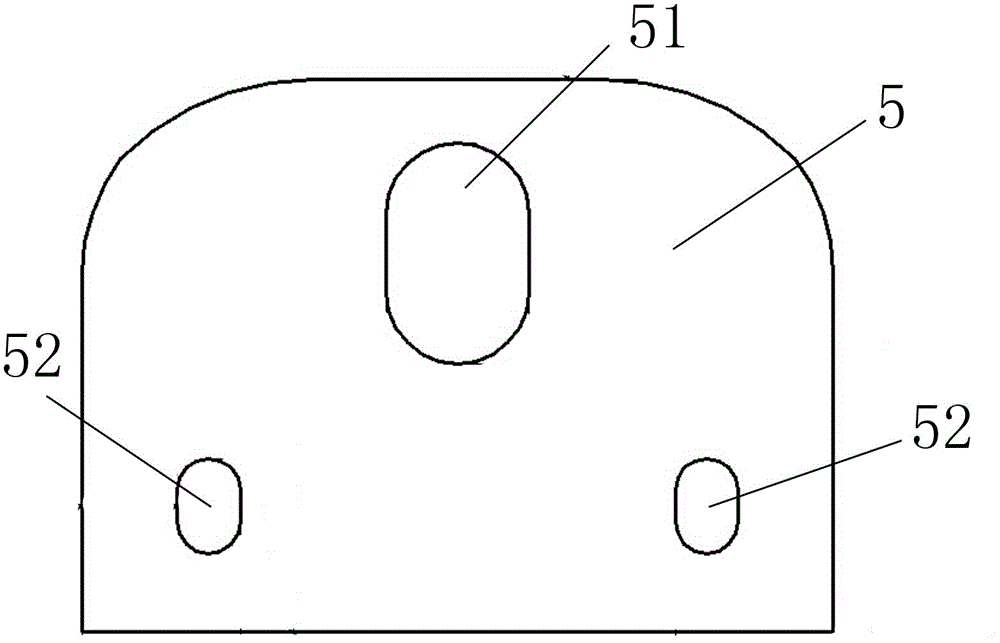

[0043] See attached picture. This embodiment takes the special-shaped column 1 with a single weight of 27t and a length of 18.45 m as an example, including the following steps:

[0044] 1) Calculate the position of the lifting point 3 on the special-shaped column 1; according to the principle of mechanical horizontality, the weight on both sides of the center of gravity of the special-shaped column 1 is equal, and the position of the center of gravity in the X-axis and Y-axis directions can be calculated; the position of the lifting point 3 should be selected in the X direction on the center of gravity line;

[0045] The lifting point 3 will cause shear damage to the reinforced concrete during the hoisting process. According to the calculation of the bearing capacity of the reinforced concrete structure, the shear strength of the stressed section at the lifting point 3 will be checked; due to the strong compressive capacity of concrete, the shearing capacity In the calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com