Prefabricated lattice beam structure for slope reinforcement and assembly overall construction method

A lattice beam and prefabricated lattice technology, applied in basic structure engineering, excavation, construction, etc., can solve problems such as formwork slippage, displacement of supporting structure quality, inability to use slope rescue engineering, and poor construction site conditions, etc. Conducive to early stabilization, compact and concise appearance, and guaranteed construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

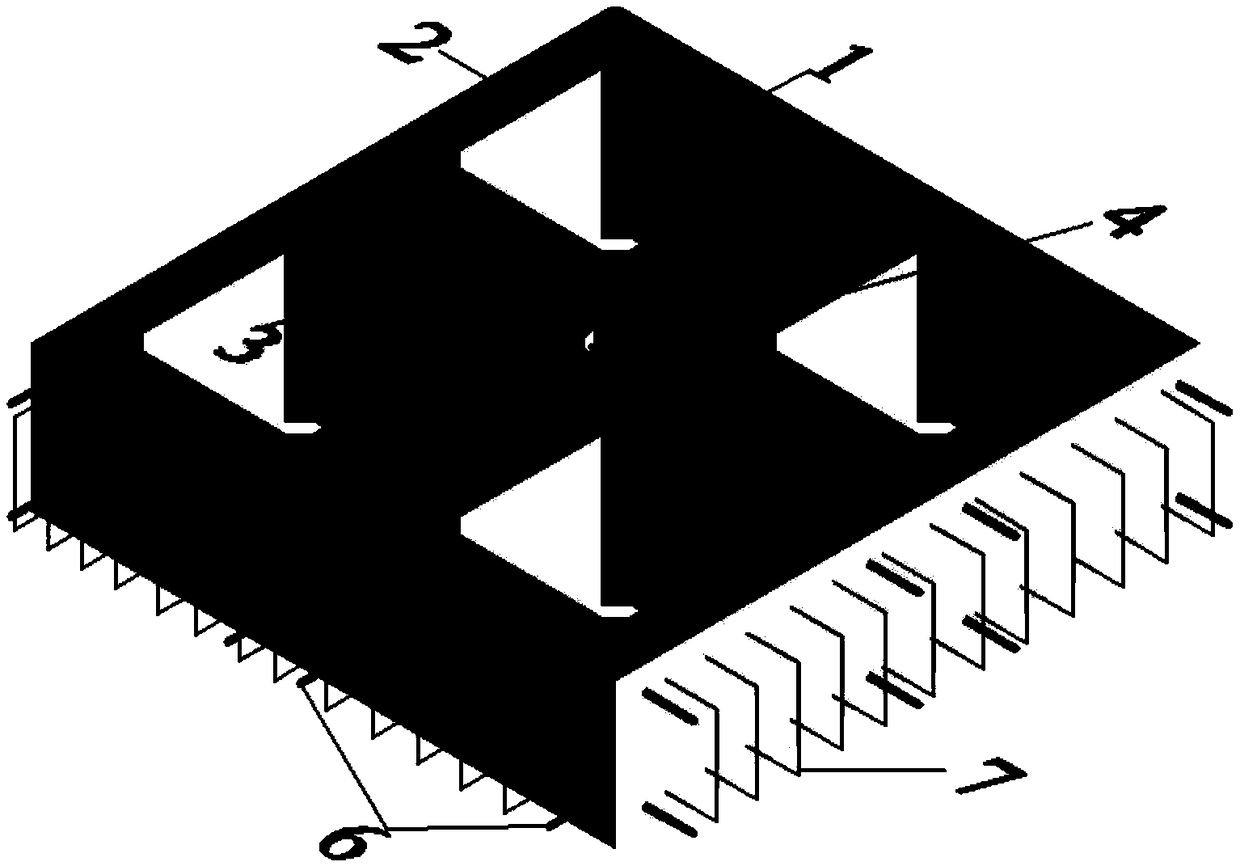

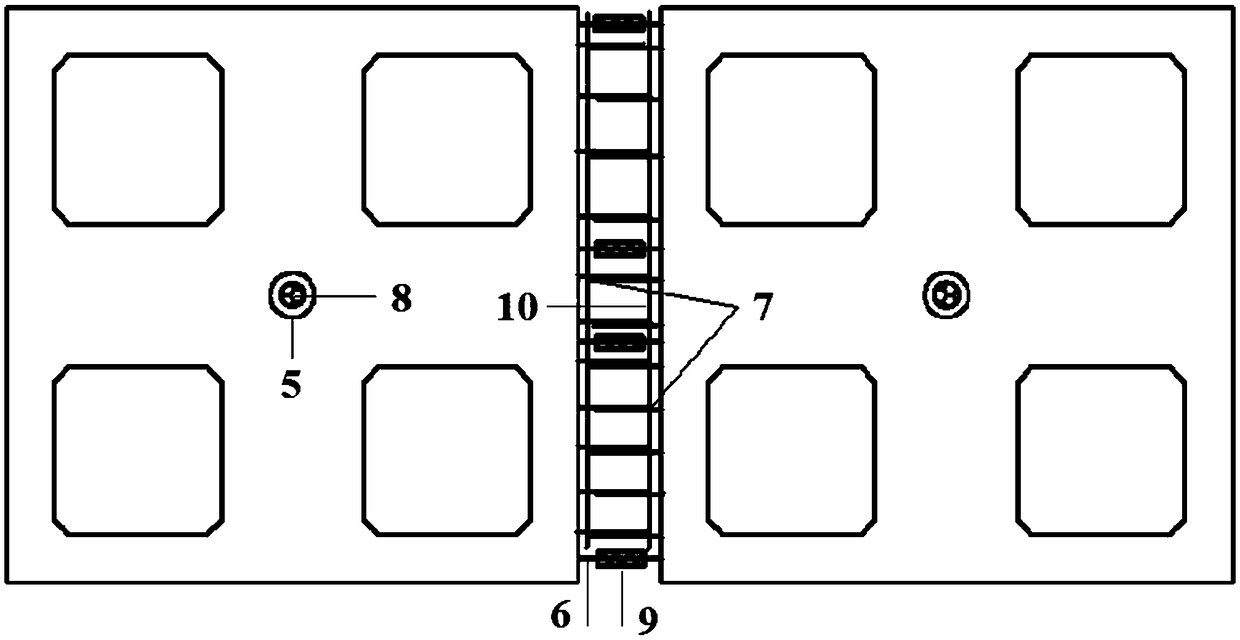

[0040] The invention provides a prefabricated lattice beam structure for slope reinforcement, see attached figure 1 , comprising: outer frame beams 1 and outer frame longitudinal beams 2; said outer frame beams 1 and said outer frame longitudinal beams 2 are orthogonally connected end to end to form a prefabricated lattice beam structure outer frame; said prefabricated lattice beam structure outer frame be square or rectangular in shape;

[0041] The inner frame beam 3 is connected to the inner side of the outer frame beam 2, and the inner frame beam 4 is connected to the inner side of the outer frame beam 1; the inner frame beam 3 is orthogonal to the inner frame beam 4;

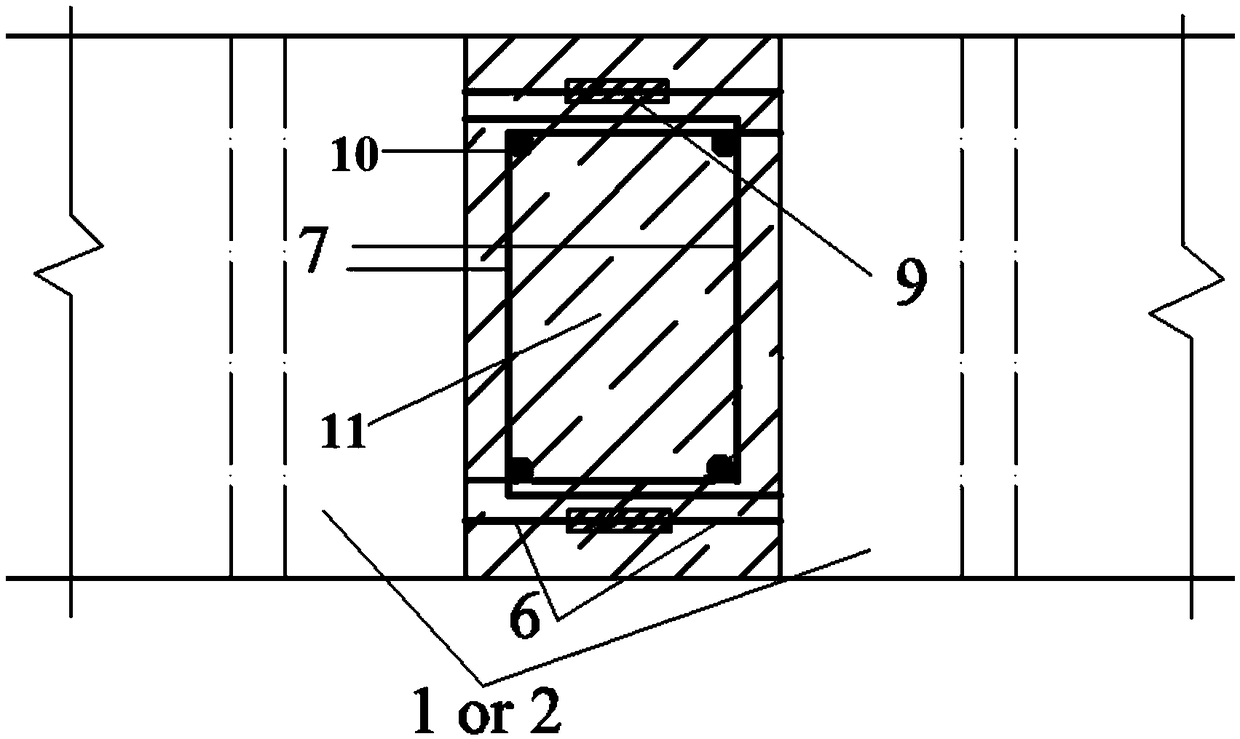

[0042]The outer side of the outer frame beam 1 and the outer frame longitudinal beam 2 is provided with a ring-shaped steel bar 7; the outer frame beam 1, the outer frame longitudinal beam 2, the inner frame beam 3 and the inner frame longitudinal beam 4 are provided with Double-layer two-way stressed main...

Embodiment 2

[0055] On the other hand, a prefabricated lattice beam structure for slope reinforcement and an overall construction method for assembly are provided. In this embodiment, a prefabricated lattice beam structure for slope reinforcement and an overall construction method for assembly is provided. An example to introduce the overall construction process of its assembly in detail. Before on-site construction, the entire slope should be pre-divided into several sections according to the needs of setting expansion joints or settlement joints in the retaining structure, and then excavated and supported in layers according to the pre-defined sections. This embodiment only introduces the overall installation process of prefabricated lattice beams for a segmented slope, and repeating this process can realize the installation process of other segmented lattice beams for the entire slope. In a segmented lattice beam assembly construction process, the prefabricated lattice beam is assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com