Homogenizing stock bin and detecting method for material level of materials in homogenizing stock bin

A technology of homogenizing silo and detection method, which is applied in the direction of measuring device, engine lubrication, liquid/fluid solid measurement, etc., can solve the problems of high purchase cost of weighing instrument, complicated installation and maintenance, etc. The effect of saving time and effort and speeding up the installation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described below with reference to the drawings.

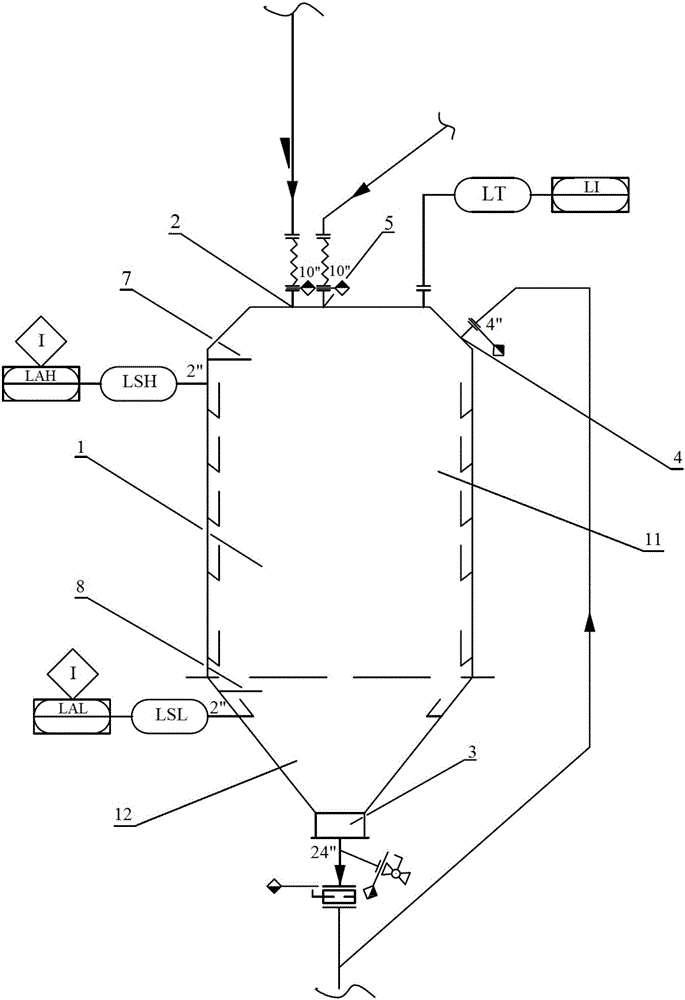

[0022] refer to figure 1 , an embodiment of the homogenization silo of the present invention, specifically, a polyethylene homogenization silo. It includes a bin body 1 for materials to be mixed therein and an ultrasonic level gauge LT for measuring the level of the materials. The ultrasonic level gauge LT is arranged on the top of the bin body 1 . In the present invention, with figure 1 The orientation shown shall prevail, and the direction from top to bottom is the direction from the top to the bottom of the warehouse body 1 .

[0023] Among them, the volume of the bin body 1 of the homogenizing silo is 910m 3 , the height is 23m. The bin body 1 has a first feed port 2 for the material from the extrusion granulator to enter the bin body 1, and the nozzle size of the first feed port 2 is 10". The bin body 1 has a discharge port 3 for feeding The material in the bin body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com