Inner diversion type self-tightening hanging part of heat exchange tube

A technology of heat exchange tubes and internal flow conduction, which is used in heat transfer modification, heat exchange equipment, cleaning heat transfer devices, etc. Heat transfer and anti-scaling and descaling, speeding up installation progress, saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

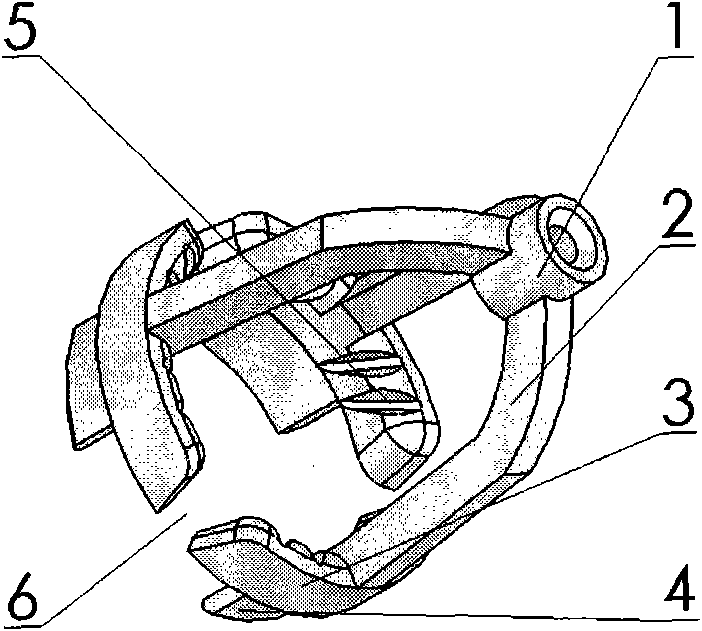

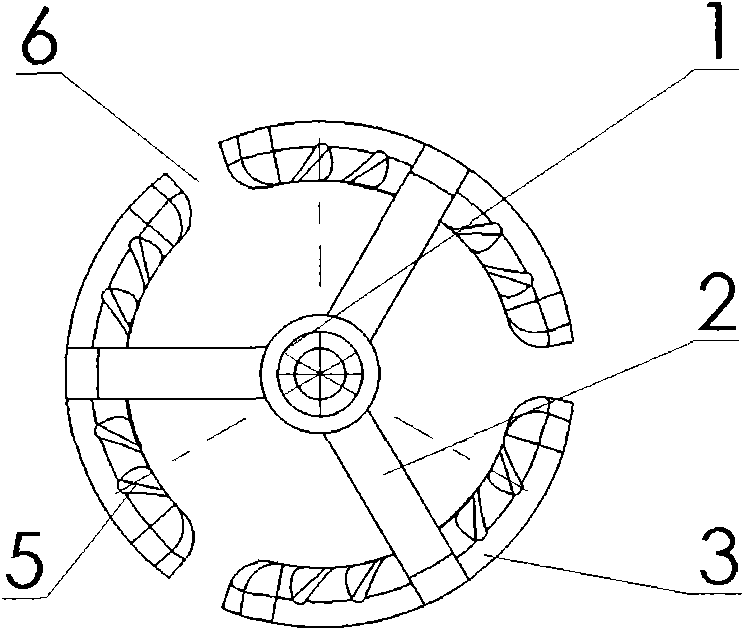

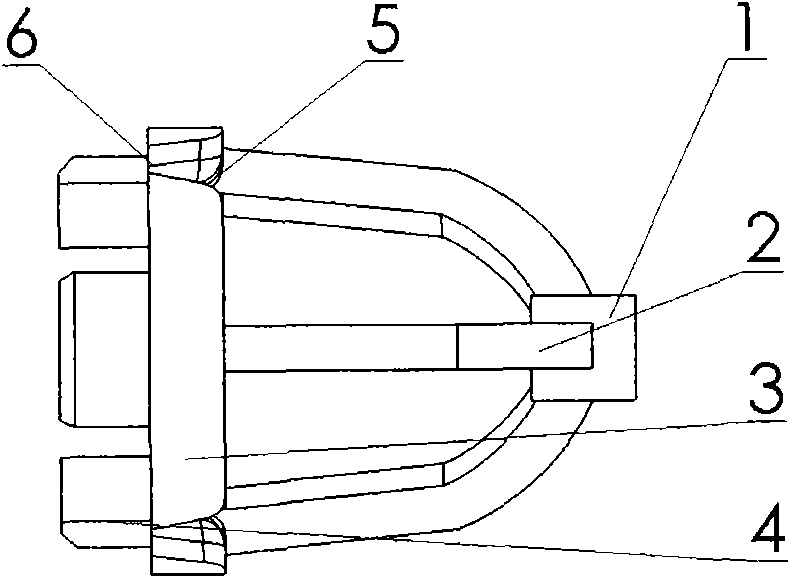

[0019] Figure 4 Shown is an implementation example of the application of the flow-guiding self-supporting hanger in the heat exchange tube of the present invention. In the figure, the flow-guiding self-supporting hanger in the heat exchange tube of the present invention is worn on both ends of the heat exchange tube 9, and the rotating shaft 7 The two ends of the pendant are respectively fixed on the pendant, and several rotors 8 are mounted on the rotating shaft 7 between the two pendants. The pendant mainly includes a hollow shaft 1, a connecting rod 2, a supporting platform 3, an extension end 4, and a connecting rod 2 is more than two. In the embodiment, there are three connecting rods 2 to ensure the stability of the support. The hollow shaft 1, the support platform 3 and the extension end 4 are concentric cylindrical bodies with inner holes. The diameter of the inner hole of the hollow shaft 1 is Slightly larger than the diameter of the rotating shaft 7, so that the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com