Axial clearance adjustment method for pumping unit

A technology of axial clearance and adjustment method, applied in the direction of pump, pump control, pump components, etc., can solve the problems that the installation quality affects the operation, management and maintenance of the water pump unit, and affects the operation efficiency and service life of the water pump unit, so as to ensure the installation quality, The effect of speeding up the installation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Rotate the two couplings of the water pump and the motor at 0°, 90°, 180°, and 270°, and measure the axial clearance b values at 4 positions at the same time. The axial clearance is b 1 -b 3 or b 2 -b 4 . (SL317-2004) "Code for Installation and Acceptance of Pumping Stations" requires that the axial clearance of rigid couplings should not be greater than 0.05-0.08mm, and the axial clearance of elastic couplings should not be greater than 0.08-0.15mm. Otherwise, the axial clearance of the pump unit needs to be adjusted.

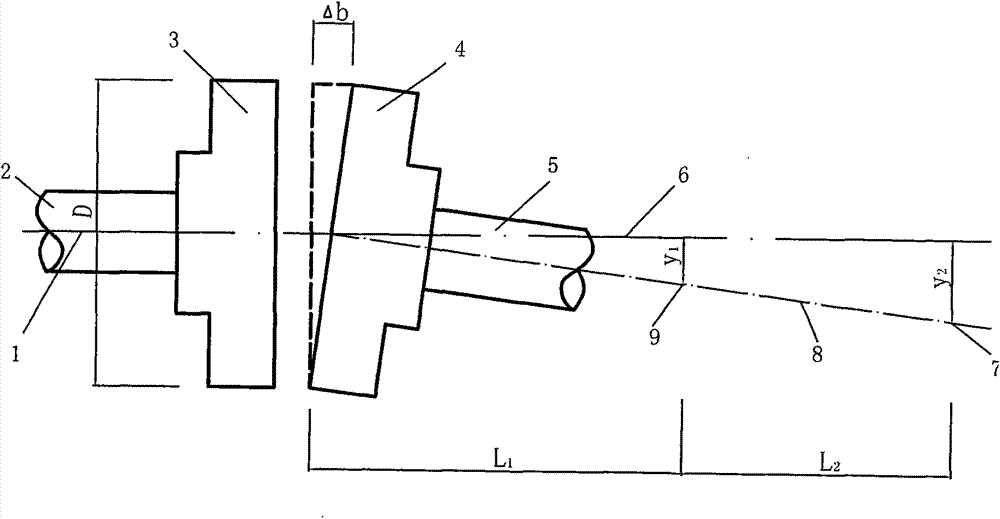

[0009] Such as figure 1 Add and subtract the thickness of the gasket at the front and rear anchor bolts of the shown motor, or the movement value of the left and right moving motors is calculated according to formula (1) and formula (2) according to the principle of similar triangles.

[0010] y 1 = L 1 Δb D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com