Installation construction process of honeycomb lightweight partition wall boards

A light-weight partition board and construction technology technology, applied to walls, building components, buildings, etc., can solve the problems of cumbersome construction procedures and high costs, and achieve the effect of simple installation and construction methods, low cost, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Construction method when there are no door and window openings in the body of wall

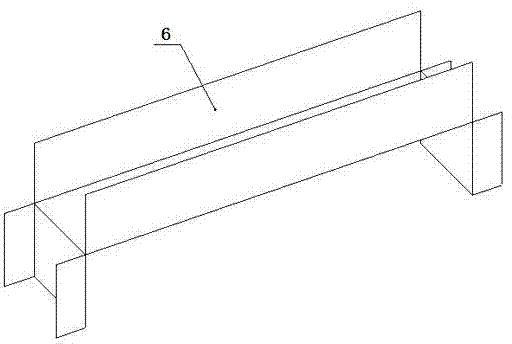

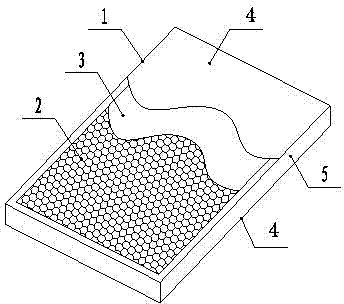

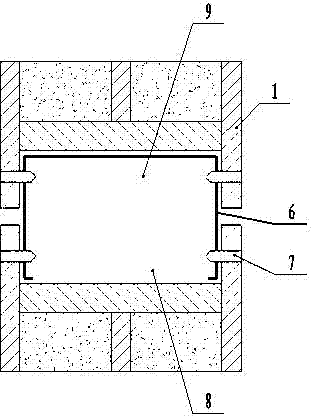

[0040] Such as figure 1 As shown in the honeycomb lightweight partition wall panel, the wall panel 1 includes more than two honeycomb paperboard filling core materials 2, several flexible composite panels 4 and sealing panels 5 for sandwiching the honeycomb paperboard filling core material 2, The honeycomb paperboard filling core material 2, the flexible composite panel 4 and the sealing panel 5 are firmly pasted together through the waterproof and heat-resistant adhesive layer 3 to form at least two closed boxes, each of which has an air cavity with a sound-insulating structure , wherein the length and width of the two flexible composite panels 4 located in the outermost layer are greater than the length and width of the flexible composite panel 4 located in the middle, forming four card slots 8, 9, upper, lower, front and rear. 10, 11;

[0041] The installation and cons...

Embodiment 2

[0057] Embodiment 2 Construction method when there are door and window openings in the body of wall

[0058] When there are door and window openings in the wall installation, the width of the edge of the wall panel 1 on the slots 8, 9, 10, 11 is equal to half of the width of the C-shaped keel flange. Compared with the construction method in the first embodiment above, The only difference is that the position of the door and window opening is marked when the wall position is laid out, and the door and window opening keel and the reinforcement structure are first erected during construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com