Adjustment method for center line of rotary kiln cylinders

An adjustment method and centerline technology are applied in the field of adjustment of the centerline of the rotary kiln, which can solve the problems of large deviation of the centerline of the cylinder, and achieve the effects of reducing the deviation of the centerline, reducing the installation cost and improving the installation progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

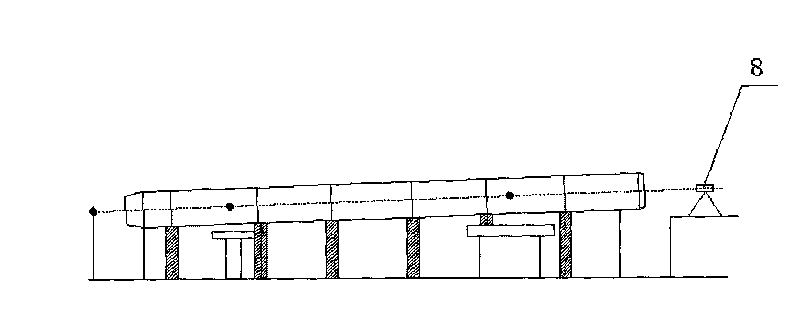

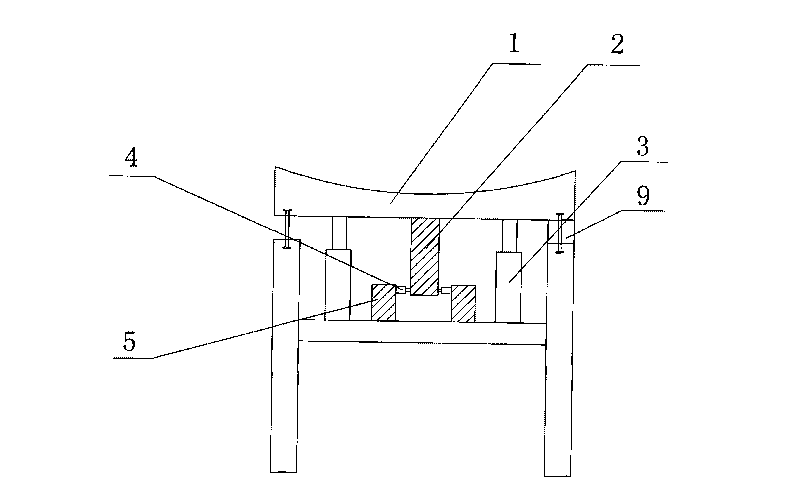

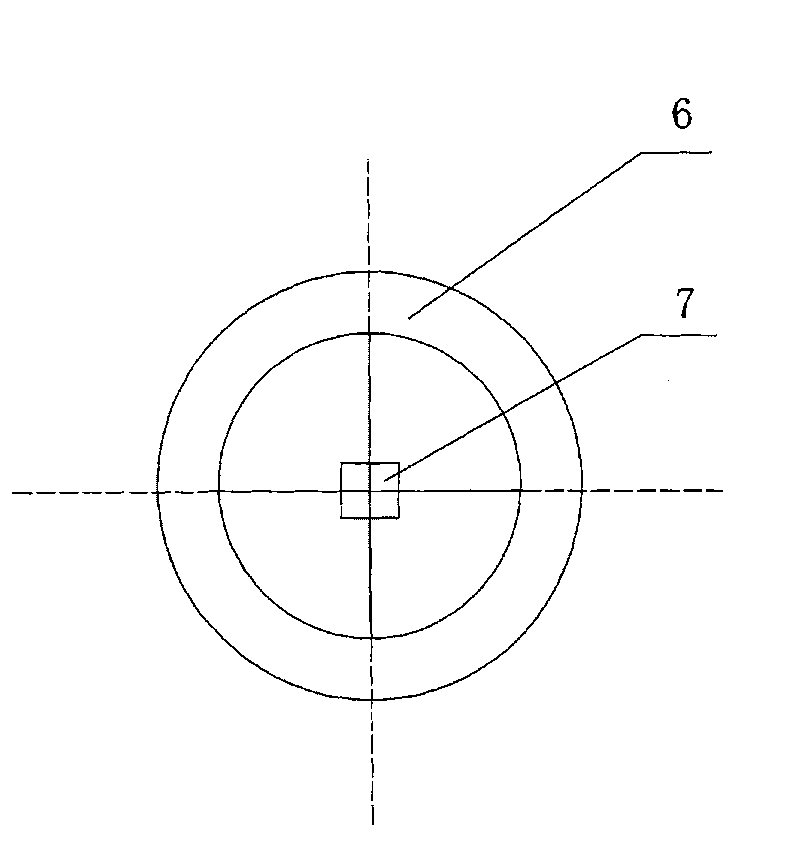

[0023] See figure 1 , figure 2 , image 3 , the adjustment method of the center line of the rotary kiln cylinder, the method includes the following steps:

[0024] 1. Coarse adjustment; connect the adjacent cylinders with bolts on the inner side of the cylinder, so that the connection ports of the adjacent cylinders are on the top;

[0025] 2. Fine adjustment;

[0026] 1) Mark the center line by the infrared measuring instrument, so that the center line of the cylinder body on the base seat of the active end and the base seat of the active end forms a line, and other cylinder bodies are adjusted based on this straight line;

[0027] 2) Adjust each cylinder by adjusting the crescent base 1, use the infrared measuring instrument 8 to measure the deviation between the center point of each cylinder and the reference line, and adjust each cylinder according to the deviation value, so that the two sides of each cylinder are The center points are all on the above reference line....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com