Porous body, its producing process & foaming apparatus used for the same production

A manufacturing method and a foaming device technology, which can be applied to other household appliances, applications, ceramic products, etc., and can solve the problem that other coal ash cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] embodiment of the invention

[0043] Embodiments of the manufacturing method of the porous body of the present invention and the foaming apparatus used for the manufacturing thereof will be described below using the drawings, but the present invention is not limited to the following embodiments.

[0044] [First embodiment]

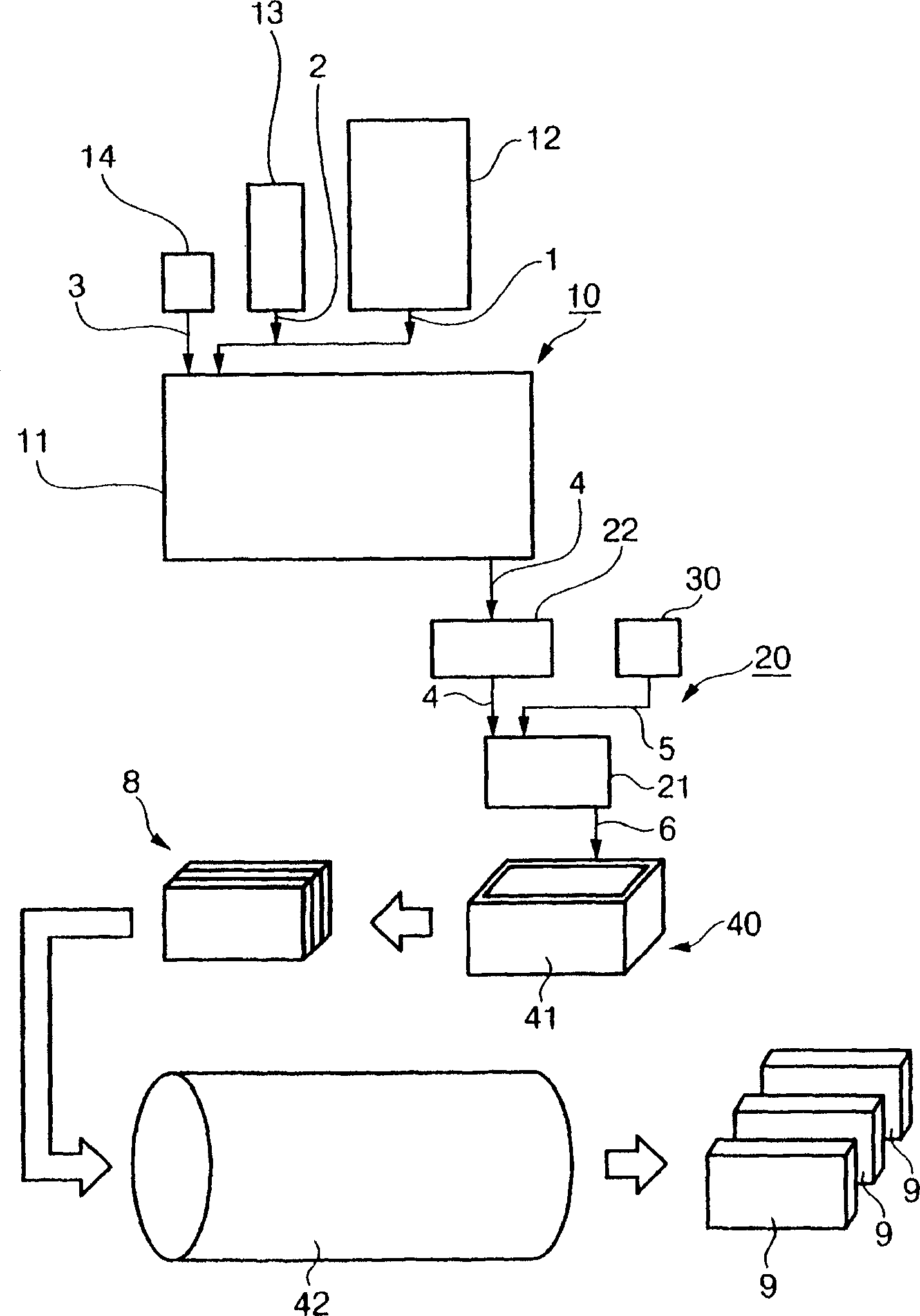

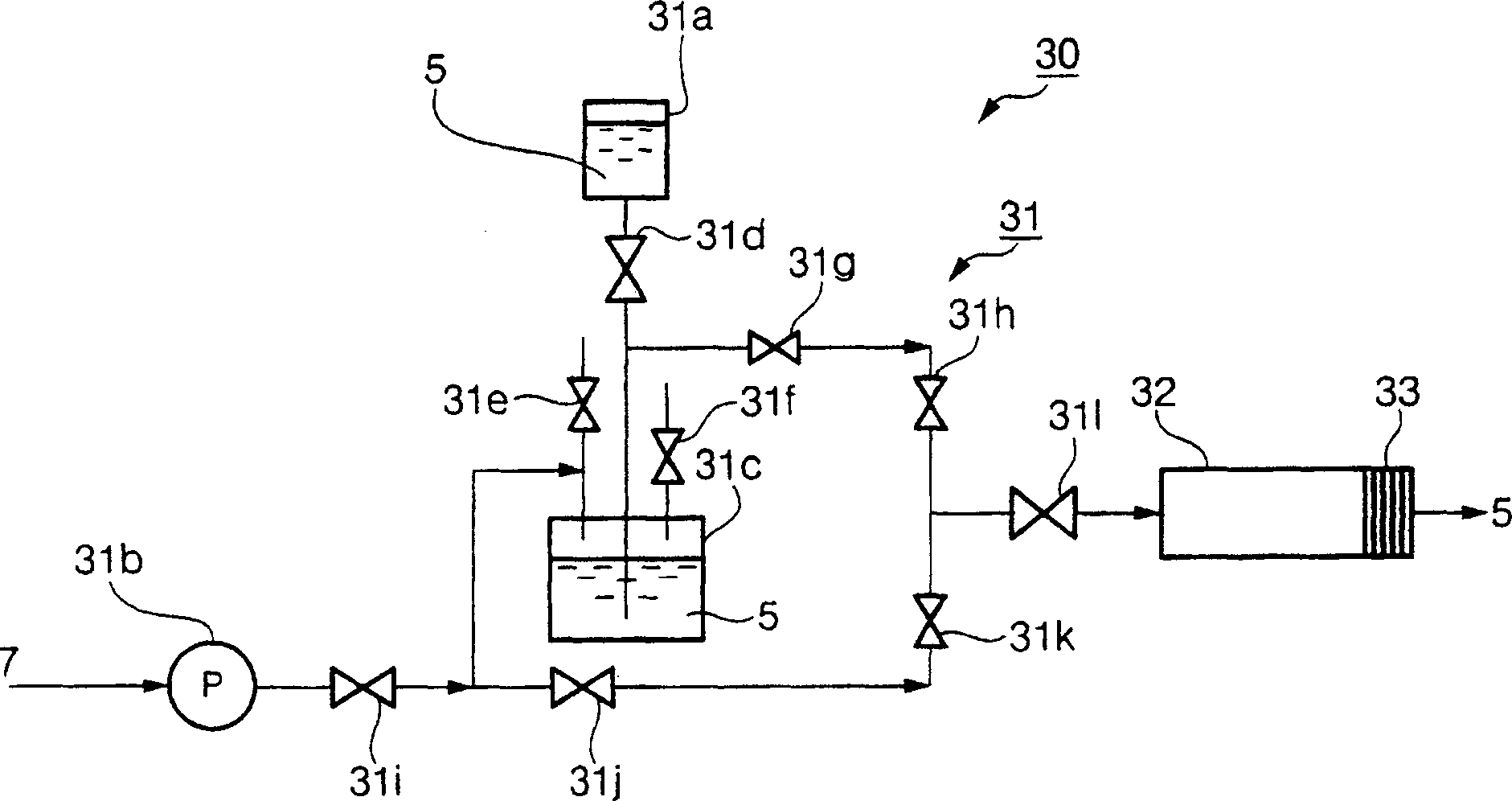

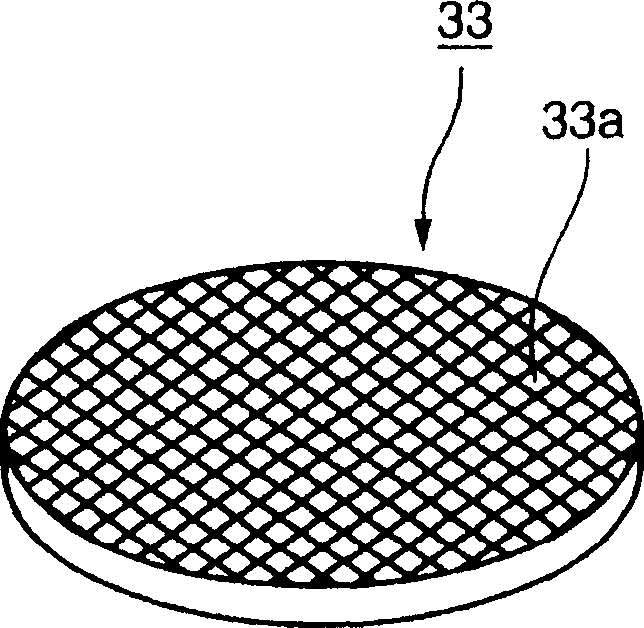

[0045] The first embodiment of the manufacturing method of the porous body of the present invention and the foaming device used in the manufacturing adopts Figure 1~3 Be explained.figure 1 It is a schematic diagram of the overall configuration of the porous body manufacturing device, figure 2 It is a schematic diagram of the composition of the foaming device, image 3 It is a schematic diagram of the structure of the mesh body.

[0046]

[0047] Such as figure 1 As shown, the porous body manufacturing apparatus of this embodiment has: a main raw material slurry manufacturing apparatus 10 that mixes the main raw materials of fly ash 1 and cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com