Efficient screening distributor

A distributing device and screening technology, which is applied in the fields of filtering and sieving, solid separation, chemical instruments and methods, etc., can solve the problems of uneven distribution, material blockage, no iron removal parts, etc., and achieve low operating cost, reasonable structure, and easy maintenance. The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

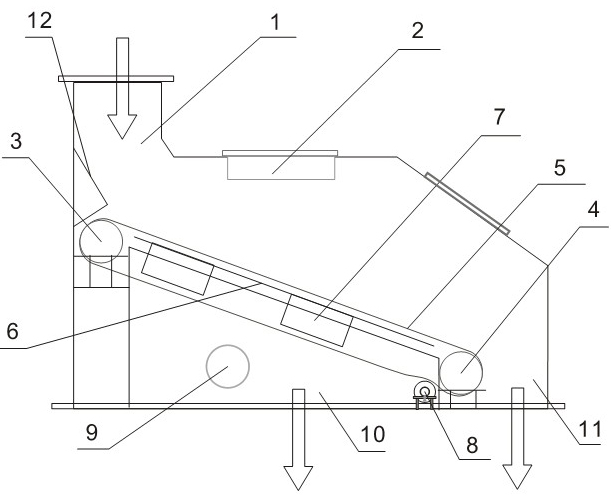

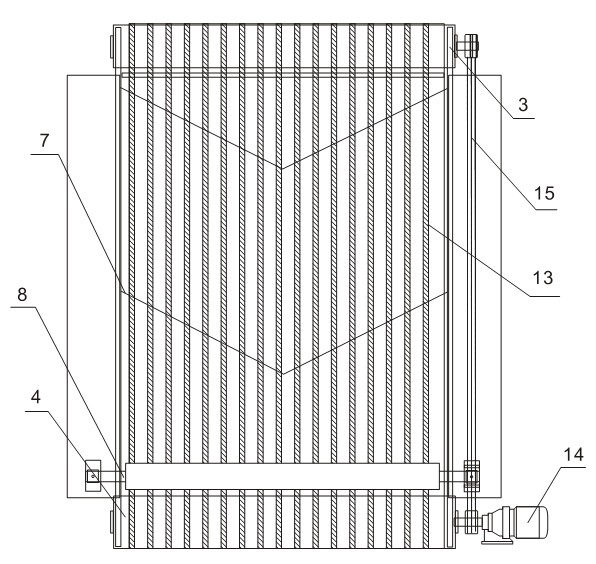

[0022] [Example 1]: as figure 1 and figure 2 , a high-efficiency screen distributor, which includes a feed port 1, an upper roller 3, a lower roller 4, a string screen surface 5, a fixed string screen 6, a coal scraping device 7, a tensioning device 8, a distribution plate 12 and The filter rope 13 and the distribution plate 12 are arranged on the inner wall below the feed port 1, the string screen surface 5 is composed of several filter ropes 13 arranged in parallel in the longitudinal direction consistent with the movement direction, and the string screen surface 5 surrounds the upper roller 3 , On the lower roller 4, two upper and lower sieve surfaces that are connected end to end and can be rotated are formed. The fixed string sieve 6 is also composed of several filter ropes arranged in parallel longitudinally, located below the upper sieve surface of the string sieve surface 5, The coal scraping device 7 is located between the upper and lower screen surfaces of the stri...

Embodiment 2

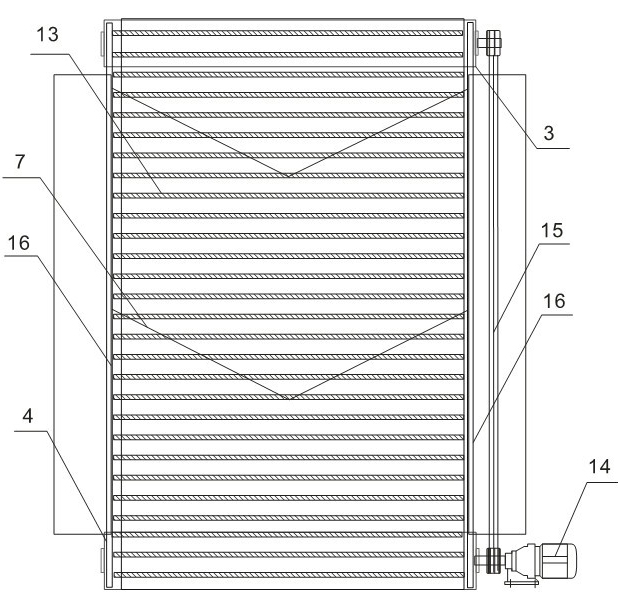

[0036] [Example 2]: as figure 1 and image 3 , a high-efficiency screen distributor, which includes a feed port 1, an upper roller 3, a lower roller 4, a string screen surface 5, a fixed string screen 6, a coal scraping device 7, a tensioning device 8, a distribution plate 12 and The filter rope 13 and the distribution plate 12 are arranged on the inner wall below the feed port 1, and the string screen surface 5 is composed of several filter ropes 13 arranged in parallel horizontally or perpendicularly to the direction of motion or at a certain angle, and the string screen surface 5 is surrounded by On the upper roller 3 and the lower roller 4, two upper and lower sieve surfaces connected end to end and can be rotated are formed. The fixed string sieve 6 is also composed of several filter ropes arranged in parallel, and is located on the upper sieve surface of the string sieve surface 5. Below, the coal scraping device 7 is located between the upper and lower screen surfaces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com