Automatic location apparatus of benchmark template for elevator and method thereof

A reference template and automatic positioning technology, which is applied in the direction of measuring devices, transportation and packaging, elevators, etc., can solve the problem of not considering the reduction of operators, and achieve the effect of saving manpower and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

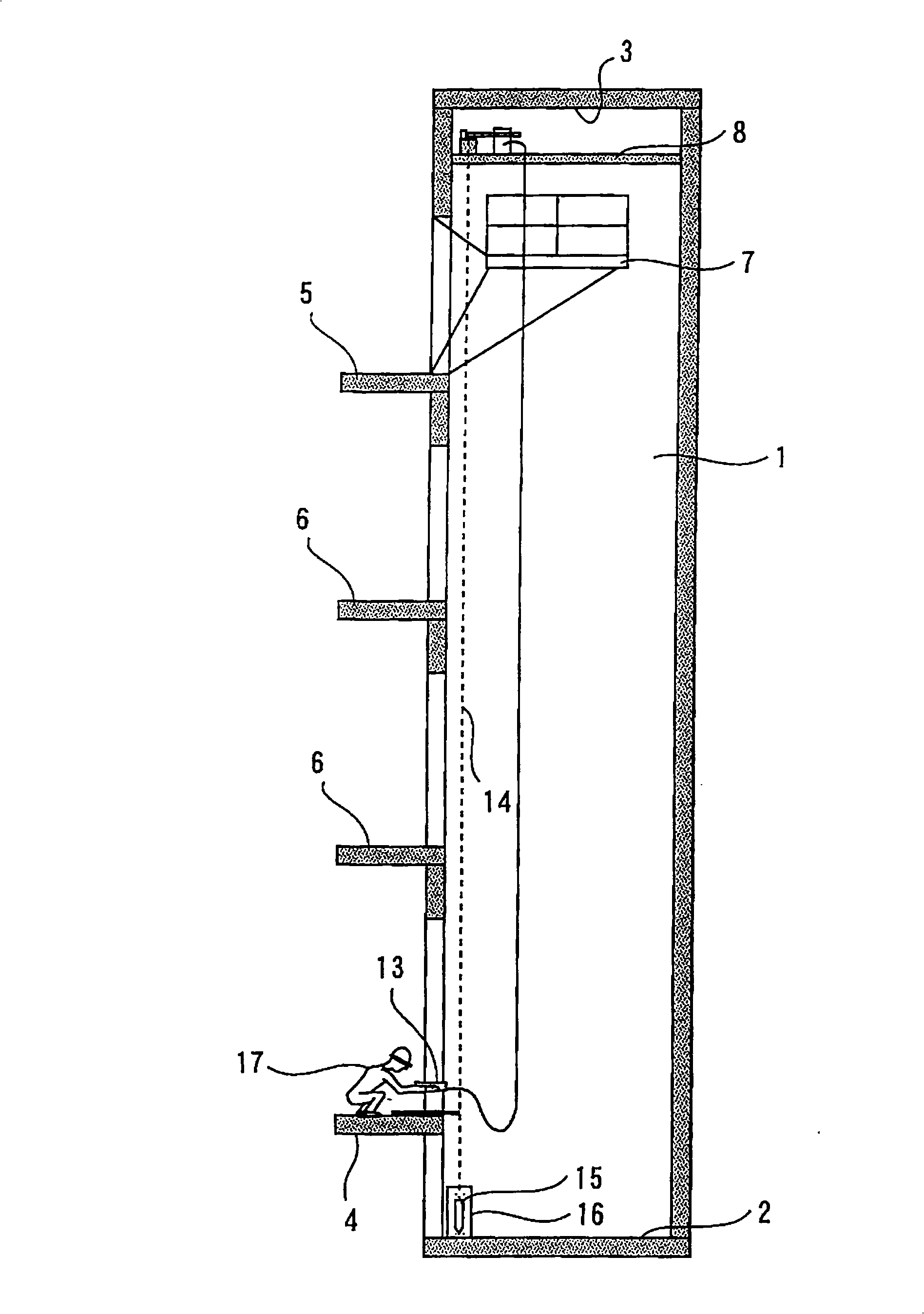

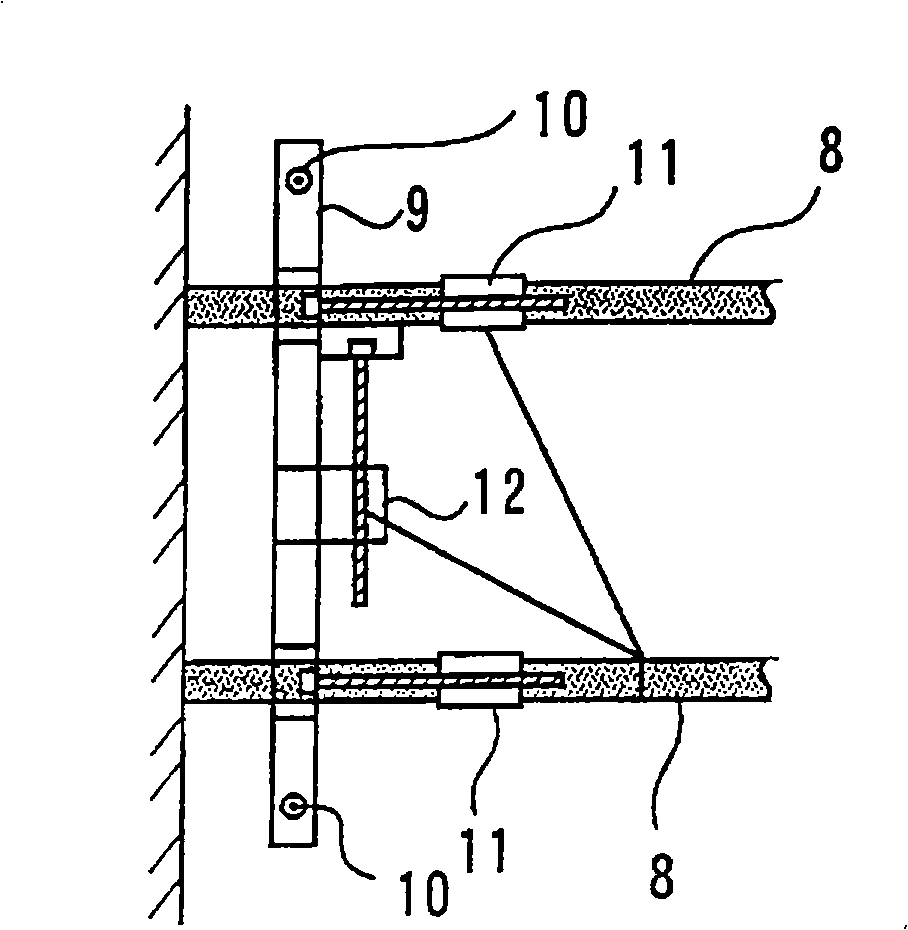

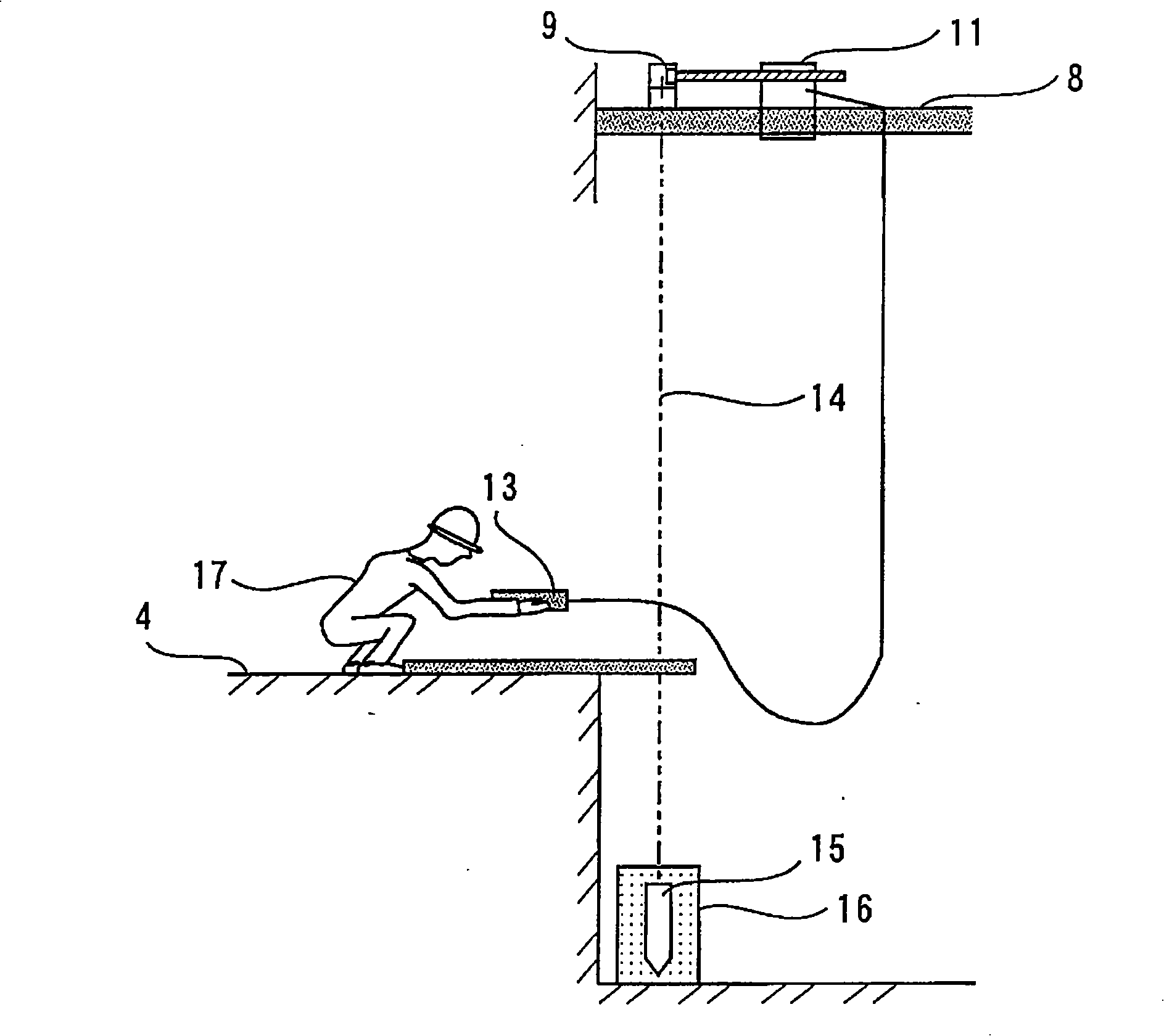

[0036] figure 1 It is an overall configuration diagram of an automatic positioning device for an elevator reference template and its method in Embodiment 1 of the present invention, figure 2 It is a partial plan view of the main part of the automatic positioning device used in the automatic positioning method of the elevator reference template in Embodiment 1 of the present invention, image 3 It is a main part side view which shows the implementation state of the automatic positioning method of the reference template for elevators in Embodiment 1 of this invention.

[0037]In the figure, 1 is the lifting path, 2 is the bottom pit of the lifting path 1, 3 is the top of the lifting path 1, 4 is the lowermost layer of the elevator room, 5 is the uppermost layer of the elevator room, and 6 is set on the lowermost layer. 4 and the middle layer formed by the multi-storey elevator room between the uppermost layer 5, 7 is the uppermost workbench arranged in the lifting path 1, and...

Embodiment approach 2

[0040] In the above-mentioned Embodiment 1, it has been explained that in the automatic positioning device and method of the reference template for elevators, the time spent on positioning the bottom piano wire becomes a problem, and most of the time spent on positioning is spent on The pendant 15 of the piano wire 14 is put into the water injection container 16 to shorten the rest time because the swing of the piano wire pendant caused by moving the template is stopped. However, in Embodiment 2, the water injection container 16 The washing agent that is made of soapy water, neutral detergent etc. replaces water, and the pendant 15 of piano wire 14 is submerged in this washing agent.

[0041] In the case of Embodiment 2, in the state where the pendant 15 is completely submerged in the detergent (100%) in the water injection container 16, the rest time is about 50 seconds, which shows the best effect of suppressing the swing of the pendant, and at the same time , Cleaning up wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com