A overflow type material rolling and chipping conveyor that separates cutting scrap with cutting lubricant

A technology of cutting oil and conveyor, which is applied in the direction of conveyor objects, transportation and packaging, metal processing machinery parts, etc. It can solve the problems of low oil separation capacity, inability to transport, and insufficient durability of screw and screw to achieve high-performance separation , excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

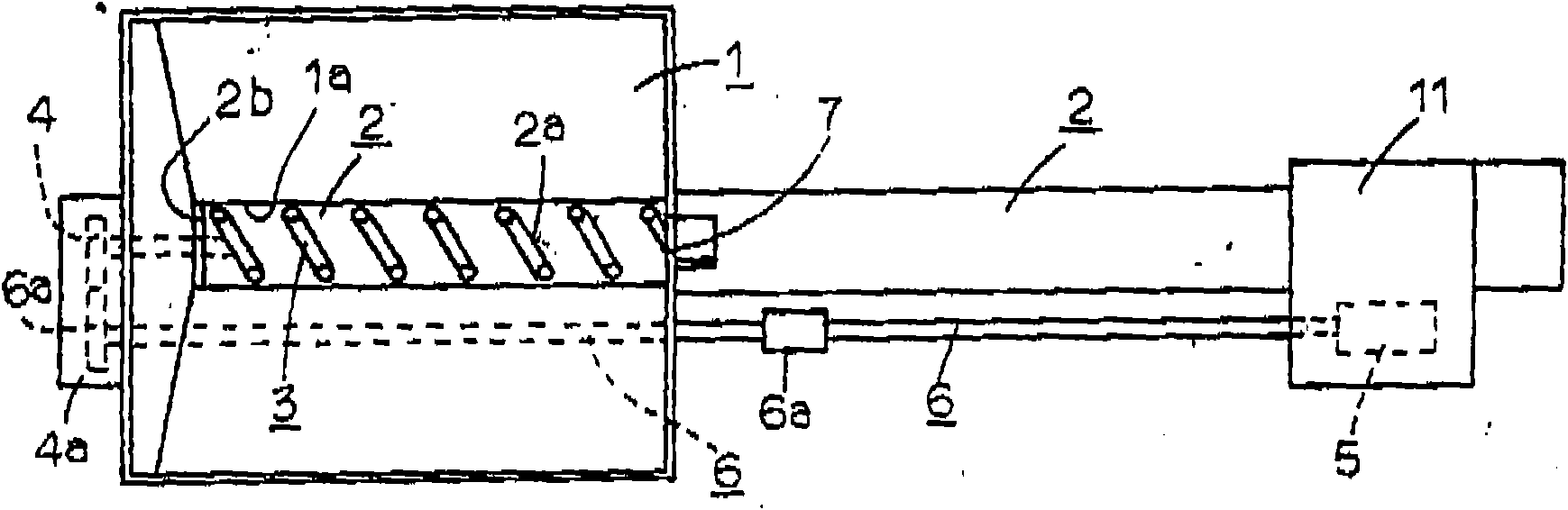

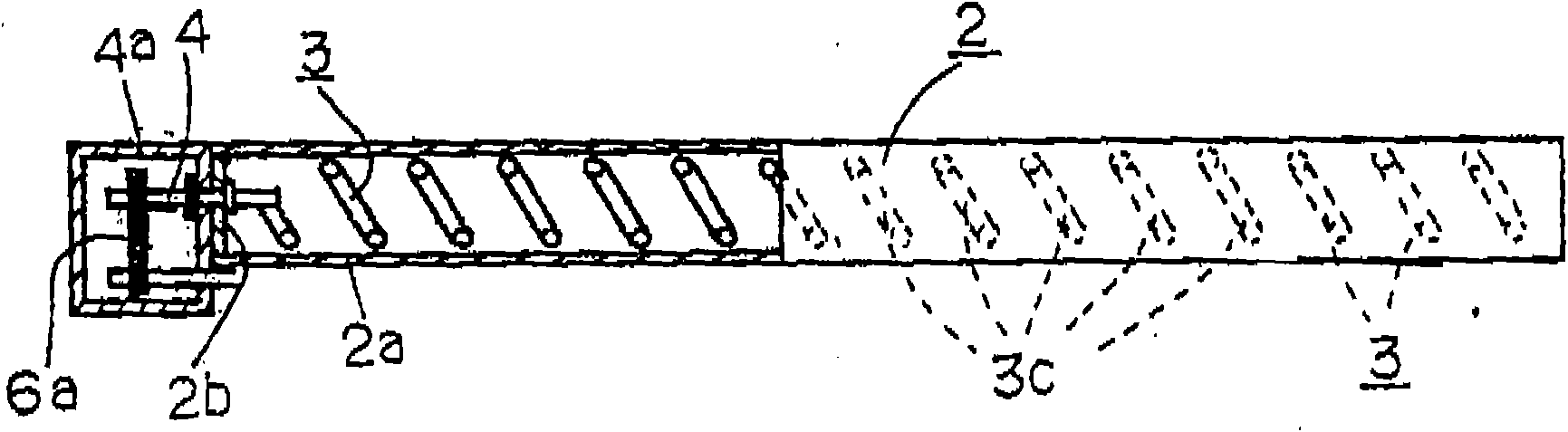

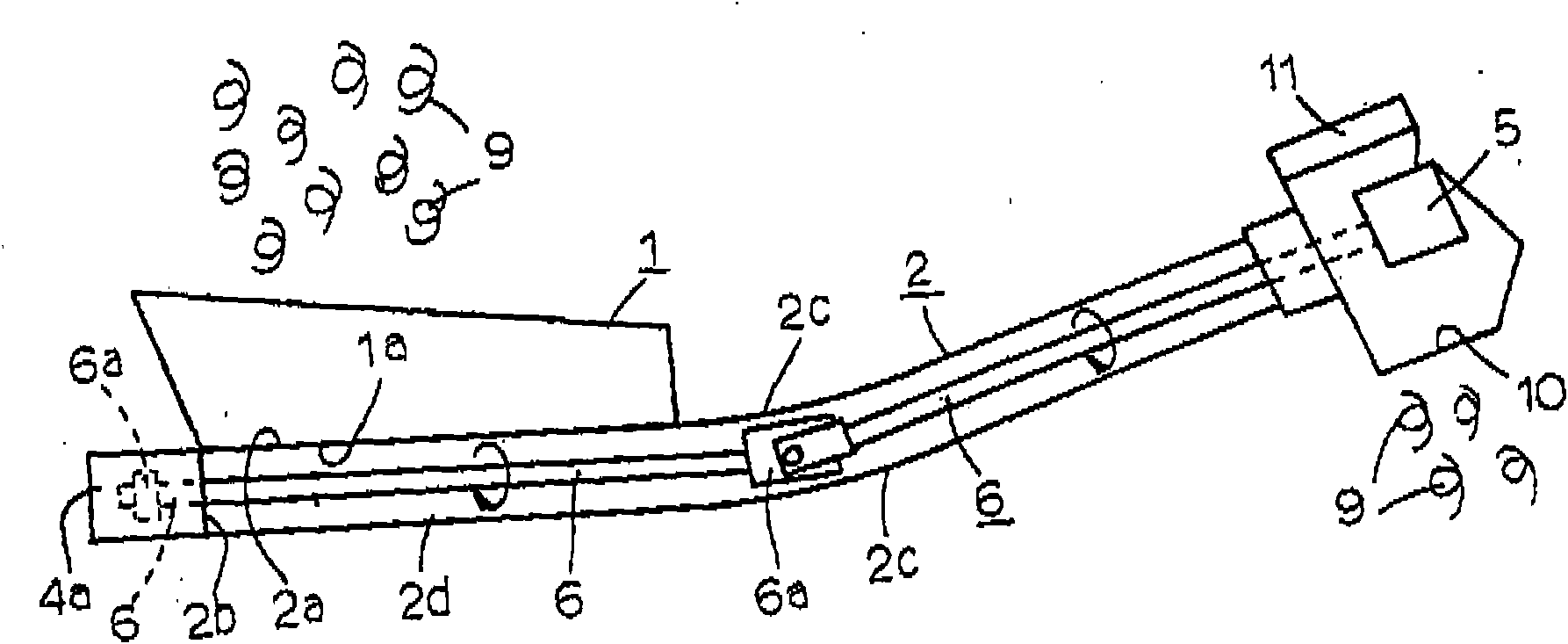

[0023] Next, a more specific embodiment of the overflow coil chip conveyor for separating chips and cutting oil according to the present invention will be described in detail with reference to the accompanying drawings. First, there is a bucket 1 . Next, there is the pipe 2 for the conveyor main body. The pipe 2 has a chip and cutting oil inlet 2a, which is in close contact with the lower opening 1a of the bucket 1, and the vicinity of the chip and cutting oil inlet 2a is horizontal. Furthermore, the front end direction of the pipe 2 is bent upward by 10° to 30°, and the bending radius R thereof is configured to be 500 mm to 1000 mm. In addition, there is a coil 3 for the conveyor main body. The coiled material 3 is accommodated in the tube 2 and extends over the entire length of the tube 2, and the material of the coiled material 3 is composed of piano wire of SWP-B in JIS standard.

[0024] Furthermore, it has the universal joint 4 for coils. One end of the web universal...

Embodiment 2

[0027] In addition, an overflow coil chip conveyor for separating chips and cutting oil according to the present invention will be described in detail using more specific embodiments with reference to the drawings. First, chips 9 and cutting oil 8 generated during the manufacture of mechanical parts (refer to image 3 ) is received and concentrated by bucket 1. The cutting oil 8 in the bucket 1 forms a pool shape, the chips 9 settle, and only the upper layer of the cutting oil 8 exits the cutting oil outlet 7 (refer to figure 1 with 3)overflow. The deposited chips 9 are conveyed by the rotation of the coil 3 , and the coil 3 is rotated by the motor 5 via the spindle 6 . In the control box 11, continuous operation and intermittent operation can be selected. Equipped with a torque limiter unit, the push needle presses the micro switch every time the motor 5 rotates once, and if it is not pressed within a predetermined time, it reverses to remove the overload. If the overloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com