Low-resistivity spring-free jig and manufacturing method thereof

A technology without springs and fixtures, used in the manufacture of measuring instruments, measuring devices, instruments, etc., can solve the problems of high low resistance requirements, inability to meet the high density and low resistance requirements of printed circuit boards, etc., and reduce contact resistance. , The effect of solving the low resistance test of the fixture and improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

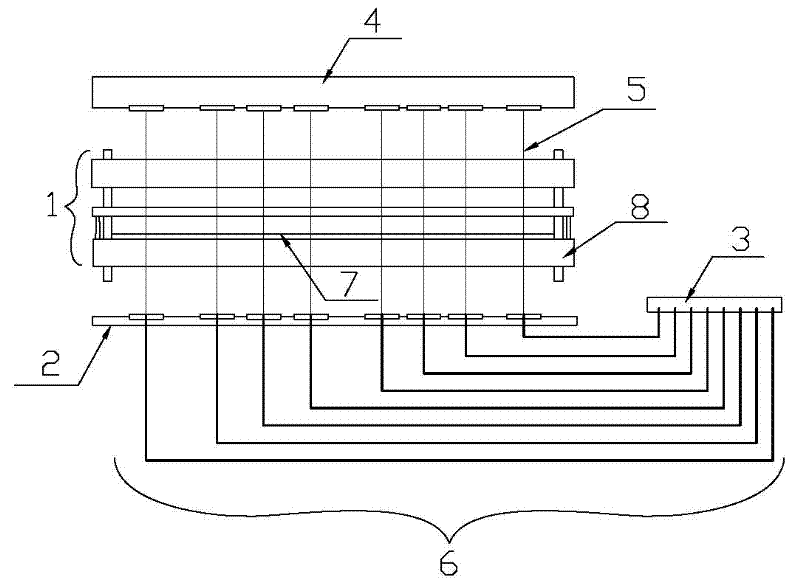

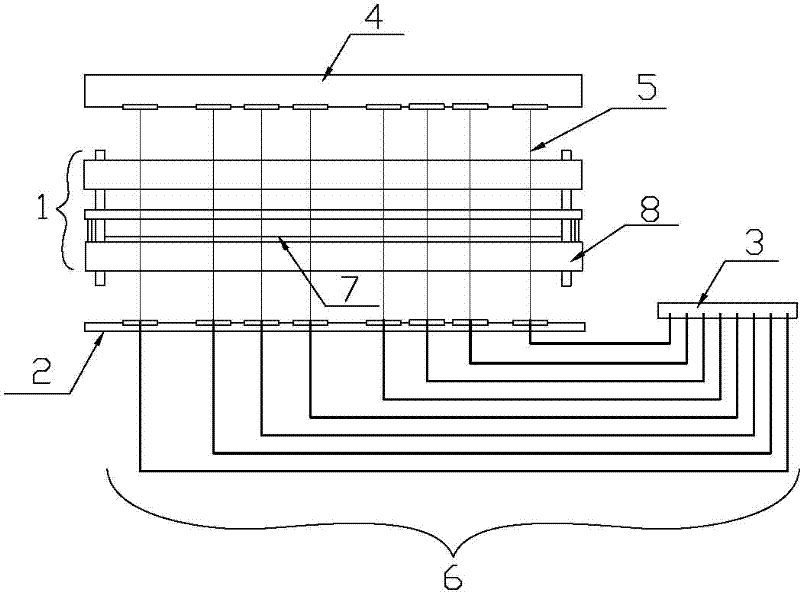

[0033] Implementation mode one: if figure 1 As shown, the low-resistance springless jig includes a needle plate 1, a wire plate 2 and a test interface 3. The needle plate 1 is composed of three insulating boards, and has through holes corresponding to the test points of the board 4 to be tested. The probe 5 is placed in the hole; the reel 2 is composed of an insulating plate, and a hole corresponding to the through hole on the lower surface of the needle disc is opened, and the wire 6 is placed in the hole, and the other end of the wire 6 is connected to the test interface 3 by welding superior. The diameter of the probe 5 is between 0.05mm and 0.15mm, and it is made of piano steel wire or rhenium tungsten wire.

[0034] The probe 5 is coated with insulating varnish or wrapped with an insulating layer except that both ends are exposed. The exposed parts of both ends of the probe 5 are electroplated with a layer of nickel, and the nickel is electroplated with a layer of gold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com