High temperature/pressure container

A high-pressure vessel, high-temperature technology, applied in the direction of pressure vessels, presses, and material forming presses used in chemical processes, can solve problems such as cost increase, and achieve the effect of reducing maintenance costs, improving performance, and shortening maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

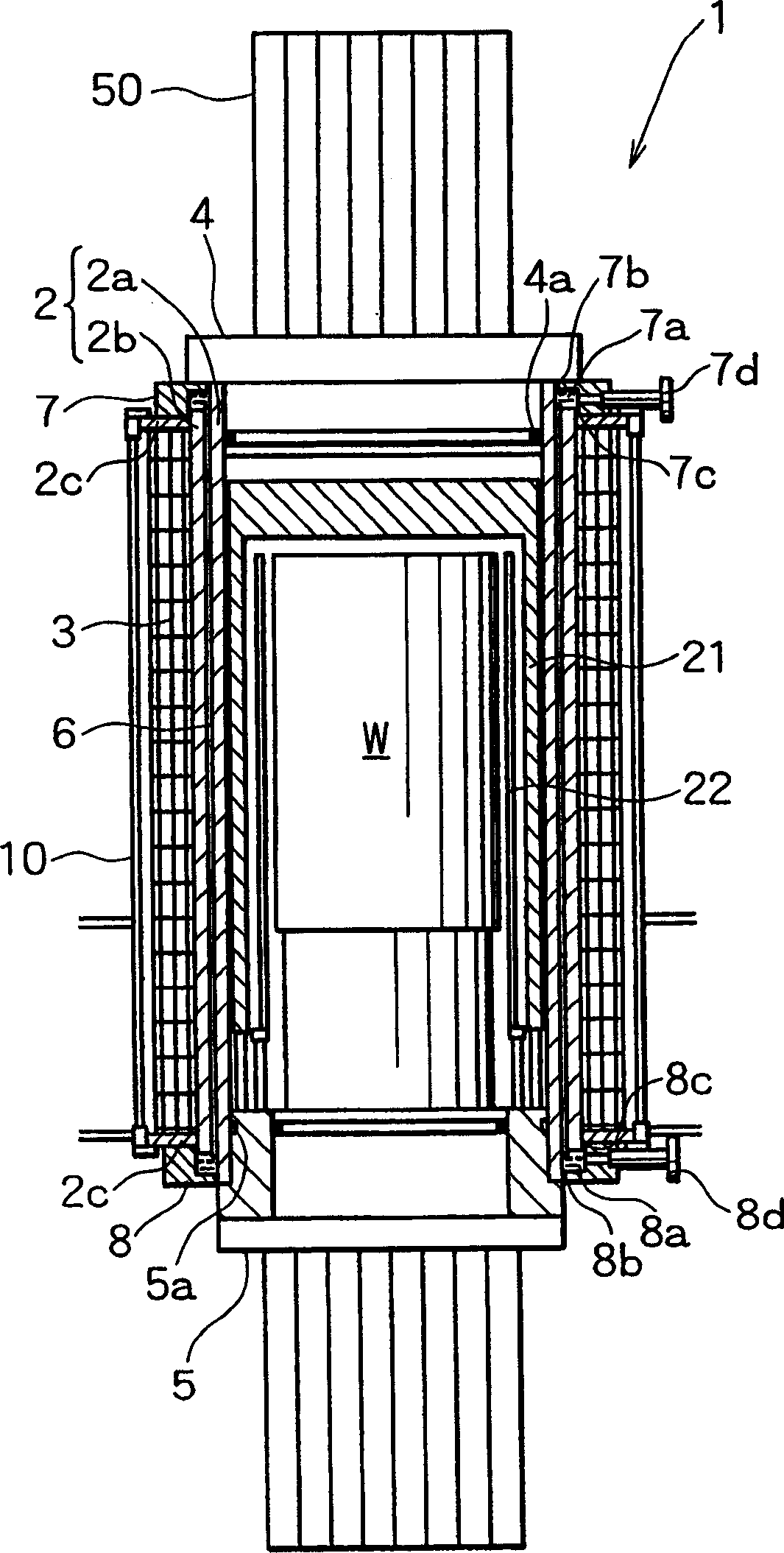

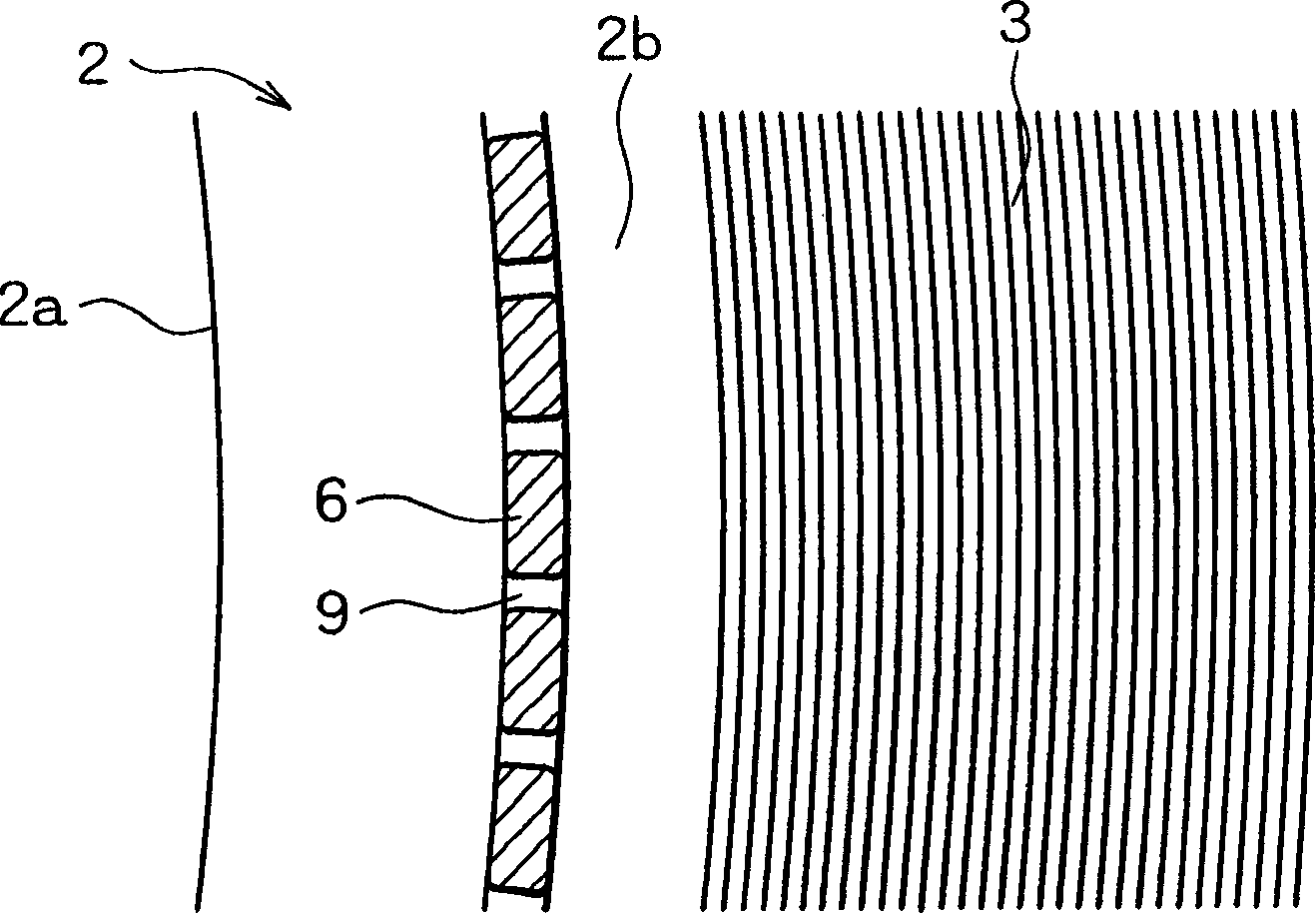

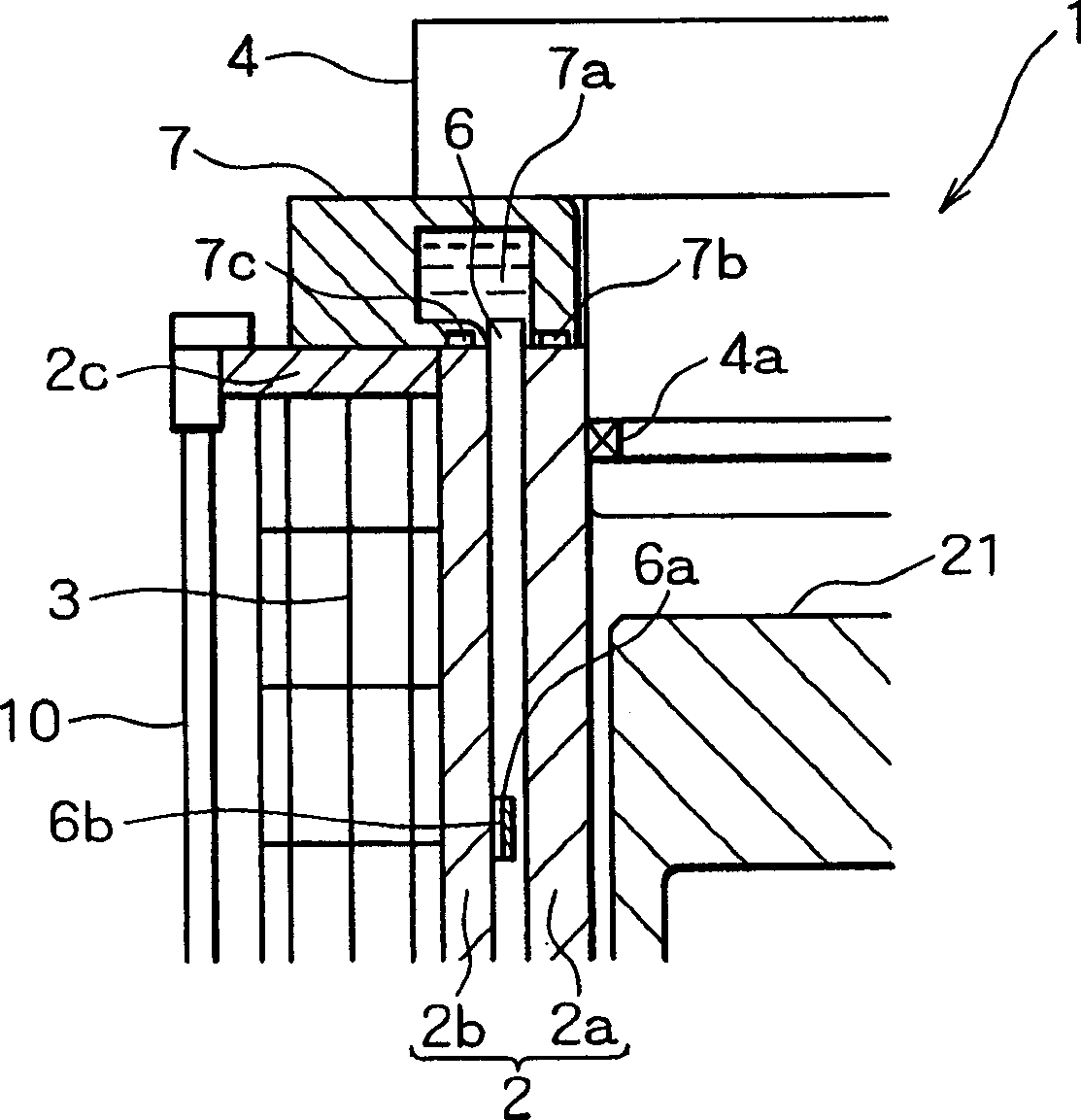

[0042]A high-temperature / high-pressure container according to Embodiment 1 of the present invention will be described here with reference to the accompanying drawings. figure 1 is a vertical cross-sectional view of a high-temperature / high-pressure vessel installed in a pressure-bearing frame; figure 2 Represents a portion of a cross-sectional view of a high temperature / high pressure vessel;

[0043] In these drawings, reference numeral 1 denotes a high-temperature / high-pressure vessel detachably installed in a pressure-receiving frame 50 . The high-temperature / high-pressure container 1 is provided with a cylindrical body 2 whose structure will be described later and a music wire wound around the outer peripheral surface of the cylindrical body 2 under a predetermined tension. The upper opening of the cylindrical main body 2 is airtightly sealed by the upper cover 4 installed thereon, and the upper cover 4 has a high-pressure sealing ring 4a as a high-pressure packing install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com