High viscosity high elasticity asphalt modifier and preparation method thereof

An asphalt modifier and a high-elasticity technology, applied in the field of asphalt modifiers, can solve the problems of difficulty in meeting the stress absorbing intermediate layer, poor low-temperature crack resistance, poor elastic recovery ability, and poor grain shape, so as to improve the fatigue resistance of pavement. performance, improve bonding properties, and improve the effect of elastic recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

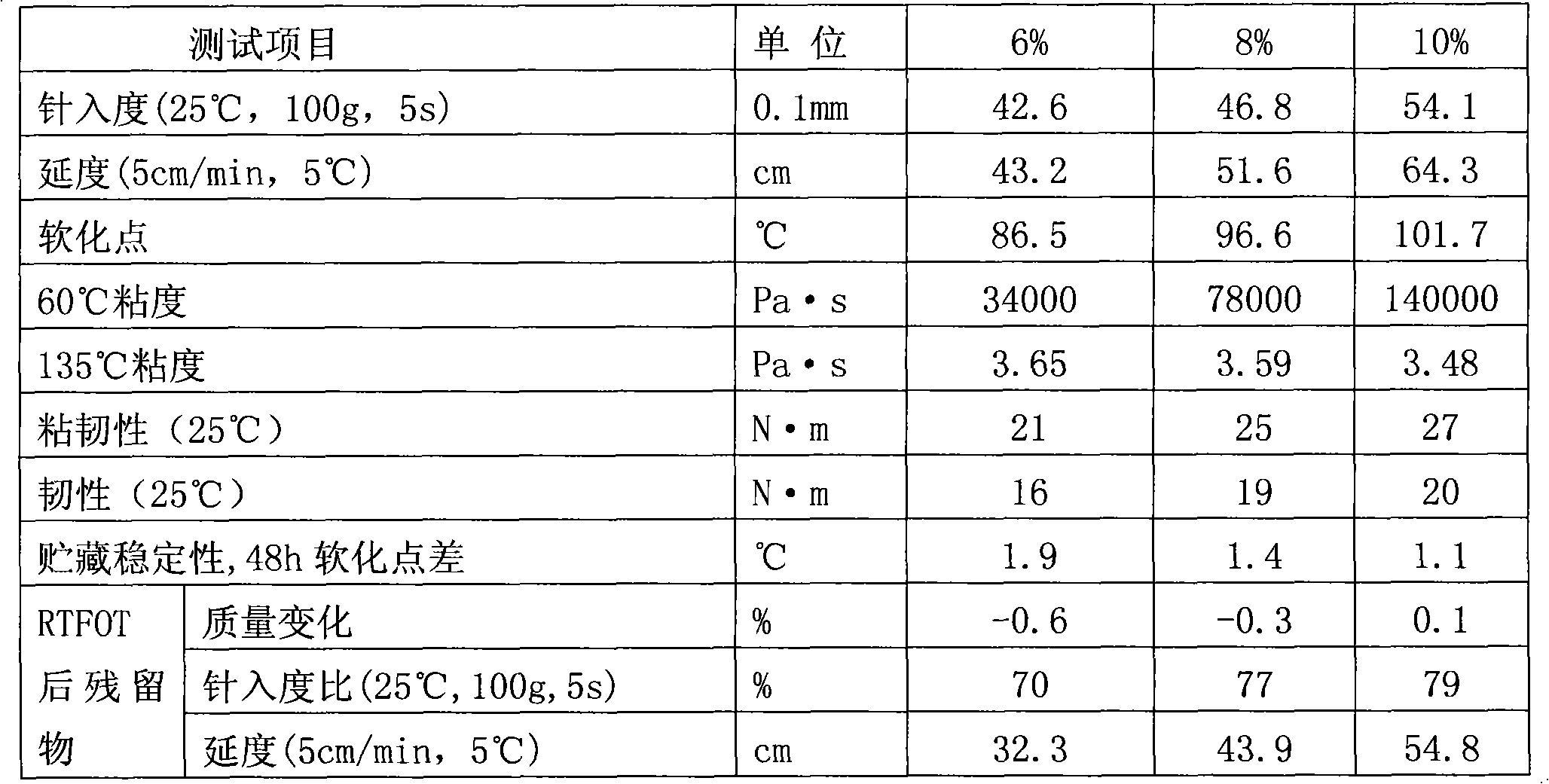

Embodiment 1

[0023] A high-viscosity and high-elasticity asphalt modifier, which is prepared from modified main agent, tackifier, anti-aging component, plasticizing component and stabilizer raw materials. The mass ratio of each raw material is: modified main agent : tackifier: anti-aging component: plasticizing component: stabilizer=100:20:18:15:2;

[0024] The modified main agent is linear styrene-butadiene-styrene block copolymer; the tackifier is petroleum resin; the anti-aging component is activated rubber powder; the The plasticizing component is dioctyl phthalate; the stabilizer is sulfur.

[0025] The preparation method of above-mentioned a kind of high-viscosity high-elasticity asphalt modifier, it comprises the steps:

[0026] 1) Selection of raw materials: according to the mass ratio of each raw material: modified main agent: tackifier: anti-aging component: plasticizing component: stabilizer = 100:20:18:15:2, select modified main Agents, tackifiers, anti-aging components, plas...

Embodiment 2

[0034] A high-viscosity and high-elasticity asphalt modifier, which is prepared from modified main agent, tackifier, anti-aging component, plasticizing component and stabilizer raw materials. The mass ratio of each raw material is: modified main agent : tackifier: anti-aging component: plasticizing component: stabilizer=100:25:20:18:3;

[0035] The modified main agent is star-shaped styrene-butadiene-styrene block copolymer; the tackifier is rosin resin; the anti-aging component is activated rubber powder; the The plasticizing component is dibutyl phthalate; the stabilizer is sulfur.

[0036] The preparation method of above-mentioned a kind of high-viscosity high-elasticity asphalt modifier, it comprises the steps:

[0037] 1) Selection of raw materials: According to the mass ratio of each raw material: modified main agent: tackifier: anti-aging component: plasticizing component: stabilizer = 100:25:20:18:3, select modified main agent Agents, tackifiers, anti-aging component...

Embodiment 3

[0043] A high-viscosity and high-elasticity asphalt modifier, which is prepared from modified main agent, tackifier, anti-aging component, plasticizing component and stabilizer raw materials. The mass ratio of each raw material is: modified main agent : tackifier: anti-aging component: plasticizing component: stabilizer=100:30:20:25:3;

[0044] The modified main agent is star-shaped styrene-butadiene-styrene block copolymer; the tackifier is petroleum resin; the anti-aging component is activated rubber powder; the The plasticizing component is dibutyl phthalate; the stabilizer is sulfur.

[0045] The preparation method of above-mentioned a kind of high-viscosity high-elasticity asphalt modifier, it comprises the steps:

[0046] 1) Selection of raw materials: according to the mass ratio of each raw material: modified main agent: tackifier: anti-aging component: plasticizing component: stabilizer = 100:30:20:25:3, select modified main agent Agents, tackifiers, anti-aging compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com