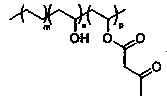

Acetoacetyl modified ethylene-vinyl alcohol copolymer and preparation method thereof

A vinyl alcohol copolymer and acetoacetyl group technology is applied in the field of polymer chemical materials to achieve the effects of improving processability, good fresh-keeping and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

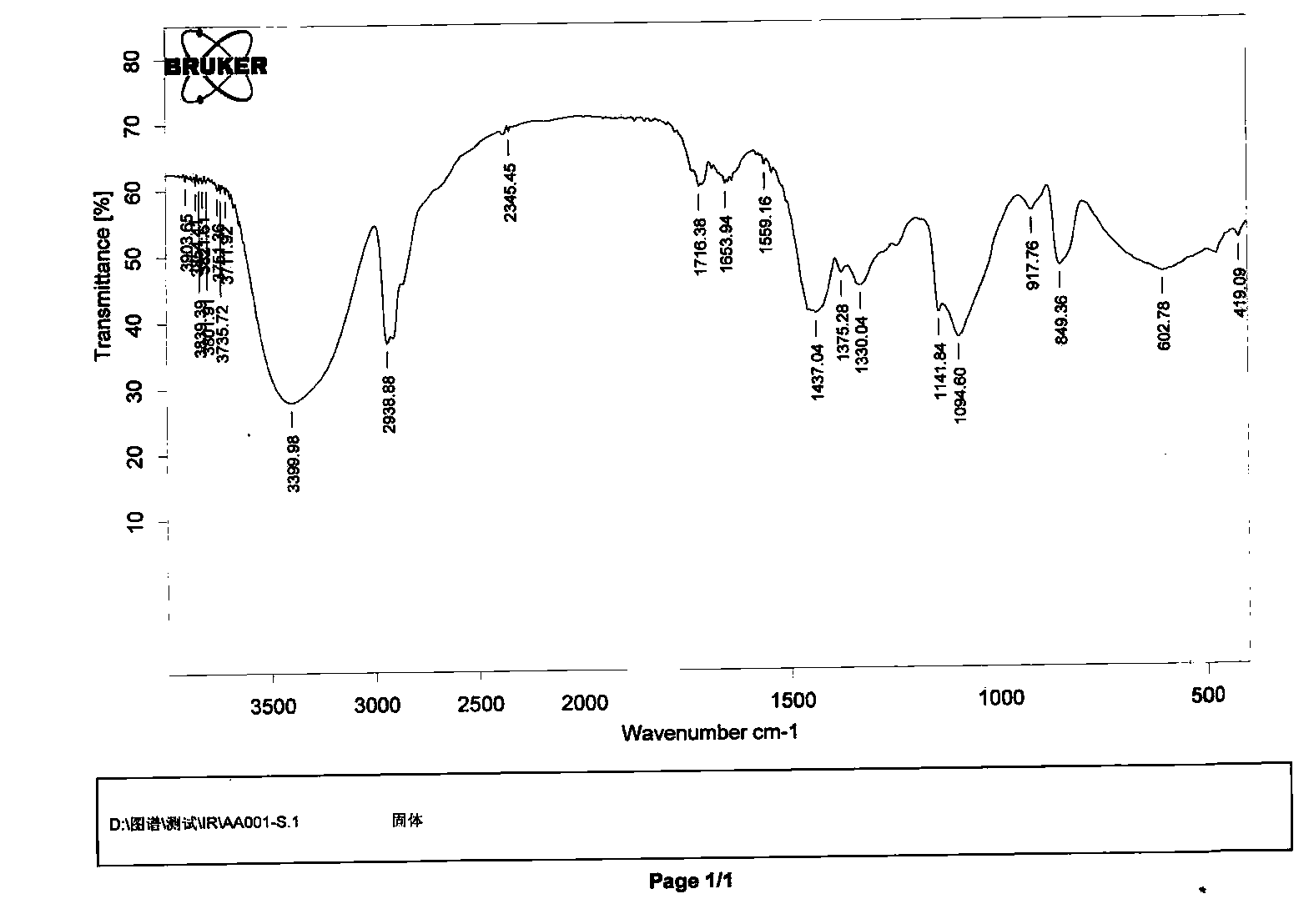

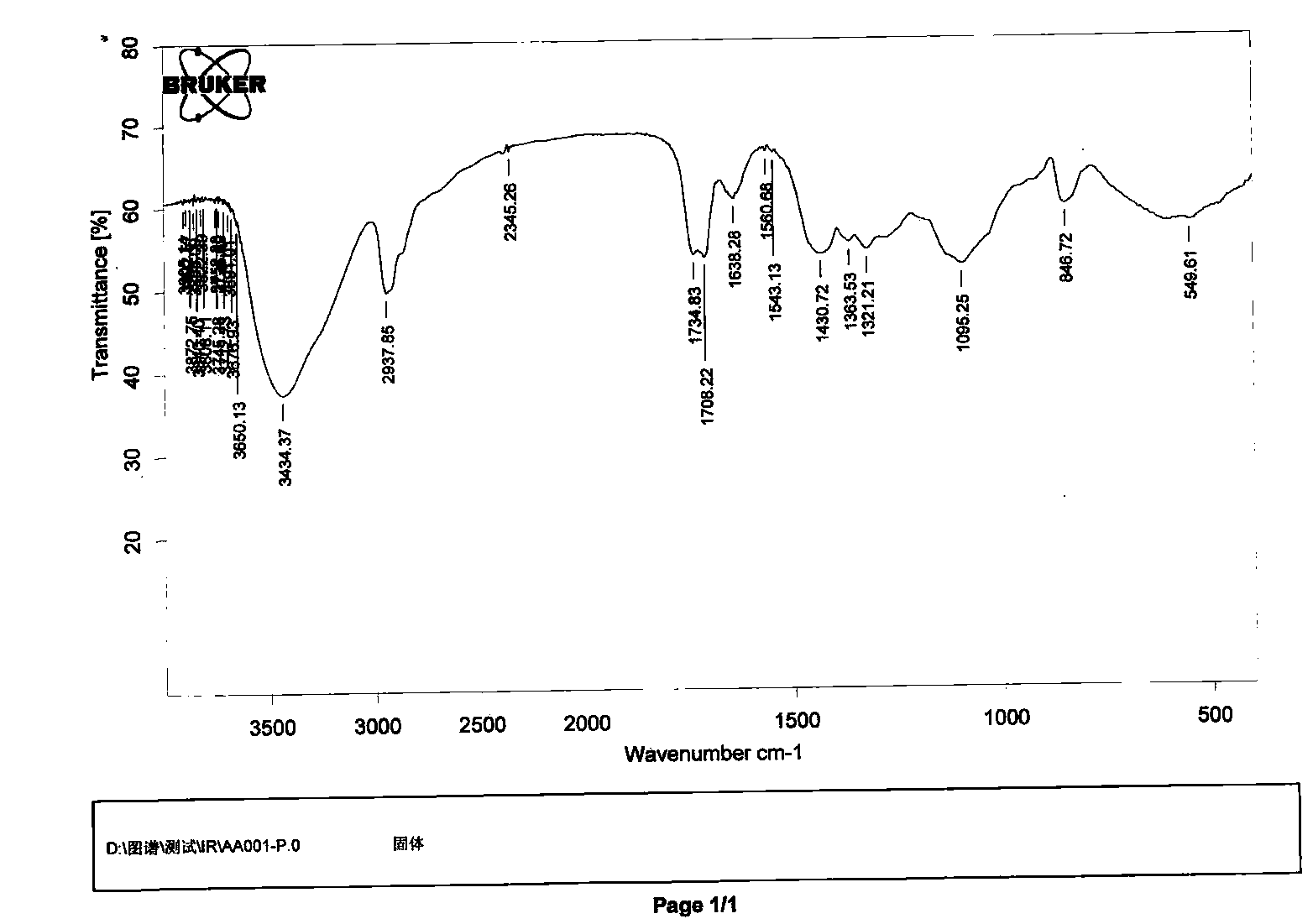

[0028] Add 50.0 g of ethylene-vinyl alcohol copolymer (EVOH) to 450 ml of dimethyl sulfoxide, heat and stir to dissolve. After the solution was cooled to room temperature, 0.1 ml of triethylamine was added dropwise to the reaction system, and then diketene (16 g, 0.190 mol) was added dropwise to the reaction system, and the dropwise was completed in 10 minutes. A large number of bubbles will be generated during the dropwise addition. After the dropwise addition, stir and react at room temperature for 8 hours. After the reaction, slowly add 3000ml butanone dropwise to the reaction solution, reflux for 2 hours after the dropwise addition, filter after cooling, and reflux the filter cake with butanone for 4 hours (400ml ×2), the resulting white powder was vacuum-dried at 80°C to obtain an acetoacetate-modified ethylene-vinyl alcohol copolymer with a mass of 49.6 g. Analysis by IR external standard method showed that the content of acetoacetyl group was 1.21mol / kg (the external s...

Embodiment 2

[0031]Add 50.0 g of ethylene-vinyl alcohol copolymer (EVOH) to 450 ml of dimethyl sulfoxide, heat and stir to dissolve. After dissolving, it was lowered to room temperature, and 0.1 ml of triethylamine was added dropwise to the reaction system, and then diketene (26 g, 0.309 mol) was added dropwise to the reaction system, and the dropwise was completed in 10 minutes. A large number of bubbles will be generated during the dropwise addition. After the dropwise addition, stir and react at room temperature for 8 hours. After the reaction, slowly add 3000ml butanone dropwise to the reaction solution, reflux for 2 hours after the dropwise addition, filter after cooling, and reflux the filter cake with butanone for 4 hours (400ml ×2), the resulting white powder was vacuum-dried at 80°C to obtain acetoacetyl-modified ethylene-vinyl alcohol copolymer with a mass of 53.6 g. According to IR external standard analysis, the content of acetoacetyl group was 2.20 mol / kg.

Embodiment 3

[0033] Add 50.0 g of ethylene-vinyl alcohol copolymer (EVOH) to 450 ml of dimethyl sulfoxide, heat and stir to dissolve. After the solution was cooled to room temperature, 0.1 ml of triethylamine was added dropwise to the reaction system, and then diketene (5.5 g, 0.065 mol) was added dropwise to the reaction system, and the dropwise was completed in 10 minutes. A large number of bubbles will be generated during the dropwise addition. After the dropwise addition, stir and react at room temperature for 8 hours. After the reaction, slowly add 3000ml butanone dropwise to the reaction solution, reflux for 2 hours after the dropwise addition, filter after cooling, and reflux the filter cake with butanone for 4 hours (400ml ×2), the resulting white powder was vacuum-dried at 80°C to obtain acetoacetyl-modified ethylene-vinyl alcohol copolymer with a mass of 46.2 g. The content of acetoacetyl group was 0.60 mol / kg by IR external standard analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com