Coating material diluent containing solvent not participating in photochemical reaction, and preparation method and application thereof

A photochemical reaction, diluent technology, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

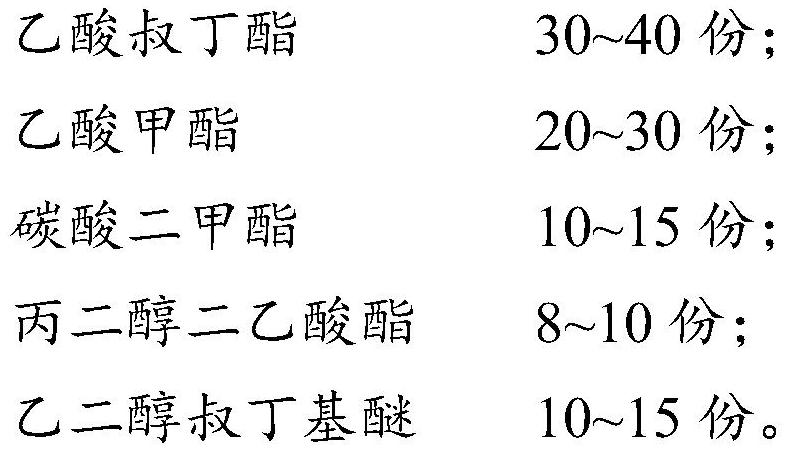

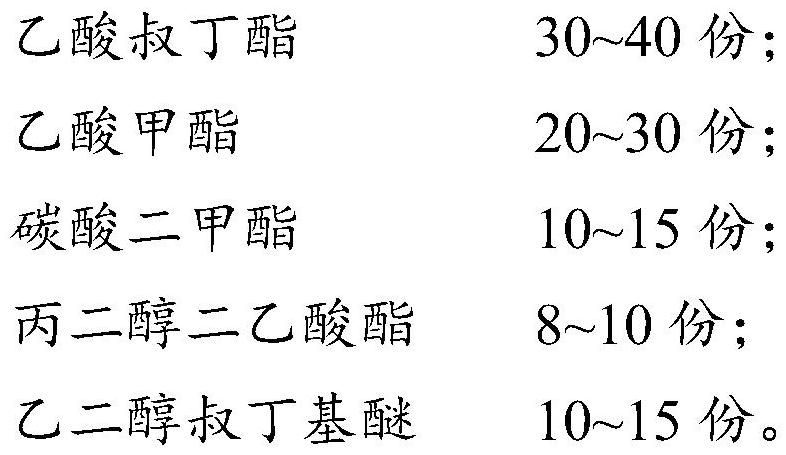

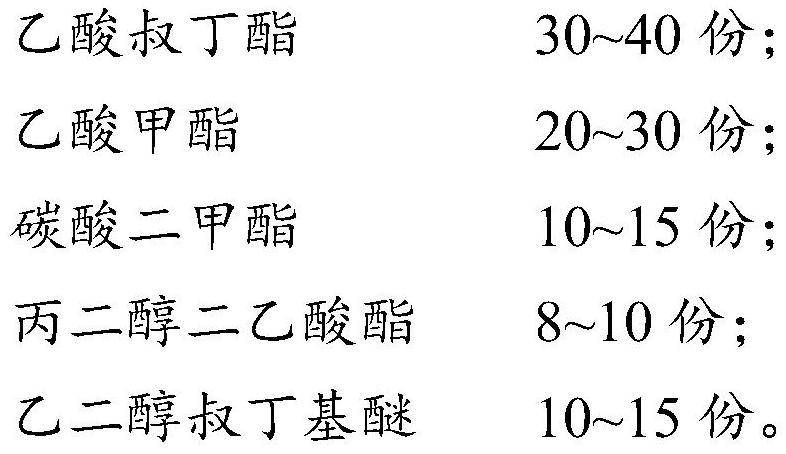

[0048] 35kg of tert-butyl acetate with a boiling point of 90°C, 28kg of methyl acetate with a boiling point of 50°C, 14kg of dimethyl carbonate with a boiling point of 85°C, 9kg of dimethyl carbonate with a flash point of 70, and a distillation range of 192 to 194 14kg of propylene glycol diacetate and 14kg of ethylene glycol tert-butyl ether with a distillation range of 152-154°C were added to the stirring tank in sequence, and stirred at a speed of 450 rpm for 30 minutes to obtain Paint thinners that participate in photochemical reaction solvents.

Embodiment 2

[0050] 570kg of tert-butyl acetate with a boiling point of 92°C, 405kg of methyl acetate with a boiling point of 52°C, 225kg of dimethyl carbonate with a boiling point of 80°C, and 150kg of dimethyl carbonate with a flash point of 72 and a distillation range of 193 to 197 150kg of propylene glycol diacetate and 150kg of ethylene glycol tert-butyl ether with a distillation range of 152-154°C were added to the stirring tank in sequence, and stirred at a speed of 500 rpm for 25 minutes to obtain Paint thinners that participate in photochemical reaction solvents.

Embodiment 3

[0052] 600kg of tert-butyl acetate with a boiling point of 90°C, 450kg of methyl acetate with a boiling point of 52°C, 150kg of dimethyl carbonate with a boiling point of 85°C, 120kg with a flash point of 72, and a distillation range of 193 to 195 150kg of propylene glycol diacetate and 150kg of ethylene glycol tert-butyl ether with a distillation range of 152-154°C were added to the stirring tank in sequence, and stirred at a speed of 600 rpm for 20 minutes to obtain Paint thinners that participate in photochemical reaction solvents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com