An extractant for purifying wet-process phosphoric acid and method for extracting wet-process phosphoric acid with it

A wet-process phosphoric acid and extractant technology, applied in chemical instruments and methods, solid solvent extraction, phosphorus compounds, etc., can solve problems such as inappropriate boiling point of extractant, large loss of product solvent, complicated process, etc., and achieve good chemistry and physics The effects of stability, simplified production process, and stable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

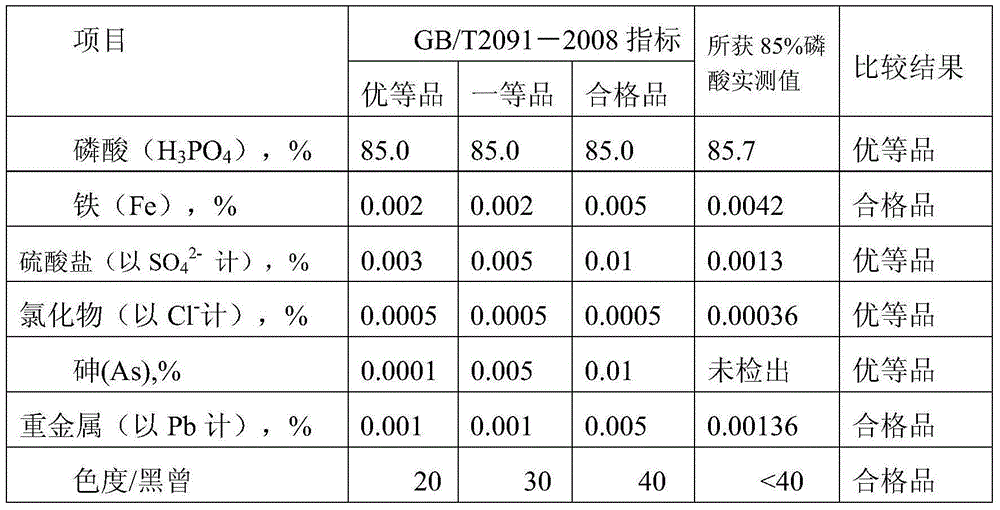

Examples

Embodiment 1

[0038] Embodiment 1: select more representative middle and low-grade phosphate rock leaching acid in Hubei Province as raw material, and the thick phosphoric acid composition of the raw material after concentration and clarification is shown in Table 1:

[0039] Table 1 raw material crude phosphoric acid composition

[0040] composition

Fe 3+

Mg 2+

Al 3+

Ca 2+

SO 4 2-

F -

SiO 2

Cl -

P 2 o 5

Quality score (%)

0.37

1.64

0.78

0.06

6.43

1.64

0.18

0.006

42.14%

[0041] (1) Rough purification: concentrate the clarified wet-process crude phosphoric acid to P 2 o 5 The mass fraction is 48%, measure the fluoride ion concentration in crude phosphoric acid, press n(F - ): n(Na 2 CO 3 )=1:1.3 Add sodium carbonate for defluorination, react at 70°C for 2 hours, settle, take the supernatant liquid and add activated carbon for decolorization, filter to obtain a crude purified pho...

Embodiment 2

[0049] Embodiment 2, with embodiment 1, difference is:

[0050] (1) Rough purification: concentrate the clarified wet-process crude phosphoric acid to P 2 o 5 The mass fraction is 30%. After reacting at 50°C for 3 hours, decolorize with activated carbon and filter to obtain a rough purified phosphoric acid solution; the defluorination rate is 78.2%.

[0051] (2) Extraction and purification: the thick purified phosphoric acid solution of step (1) gained is countercurrently added to extractant, extractant: the volume ratio=3: 1 of rough purified phosphoric acid, carry out 7 grades of extractions at normal temperature, at the entrance of rough purified phosphoric acid Sulfuric acid is added in the sixth stage to make the concentration of sulfuric acid in the raffinate phase reach 9.2mol / L; the mass fractions of the components of the extractant are: n-butanol 79%, iso-octanol 21%.

[0052] Extraction phase: washing phase volume ratio=20: 1, carry out six-stage countercurrent was...

Embodiment 3

[0054] Embodiment 3, with embodiment 1, difference is:

[0055] (1) Rough purification: concentrate the clarified wet-process crude phosphoric acid to P 2 o 5 The mass fraction is 42%. After reacting at 60°C for 3 hours, decolorize with activated carbon and filter to obtain a rough purified phosphoric acid solution; the defluorination rate is 76.7%.

[0056] (2) Extraction and purification: the thick purified phosphoric acid solution of step (1) gained is countercurrently added to extractant, extractant: the volume ratio=2: 1 of rough purified phosphoric acid, carry out 7 grades of extractions at normal temperature, at the entrance of rough purified phosphoric acid Sulfuric acid is added in the sixth stage to make the concentration of sulfuric acid in the raffinate phase reach 4.0mol / L; the mass fractions of the components of the extractant are: 50% n-butanol and 50% n-butyl ether.

[0057] Extraction phase: washing phase volume ratio=15: 1; According to the extraction phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com