Hot plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

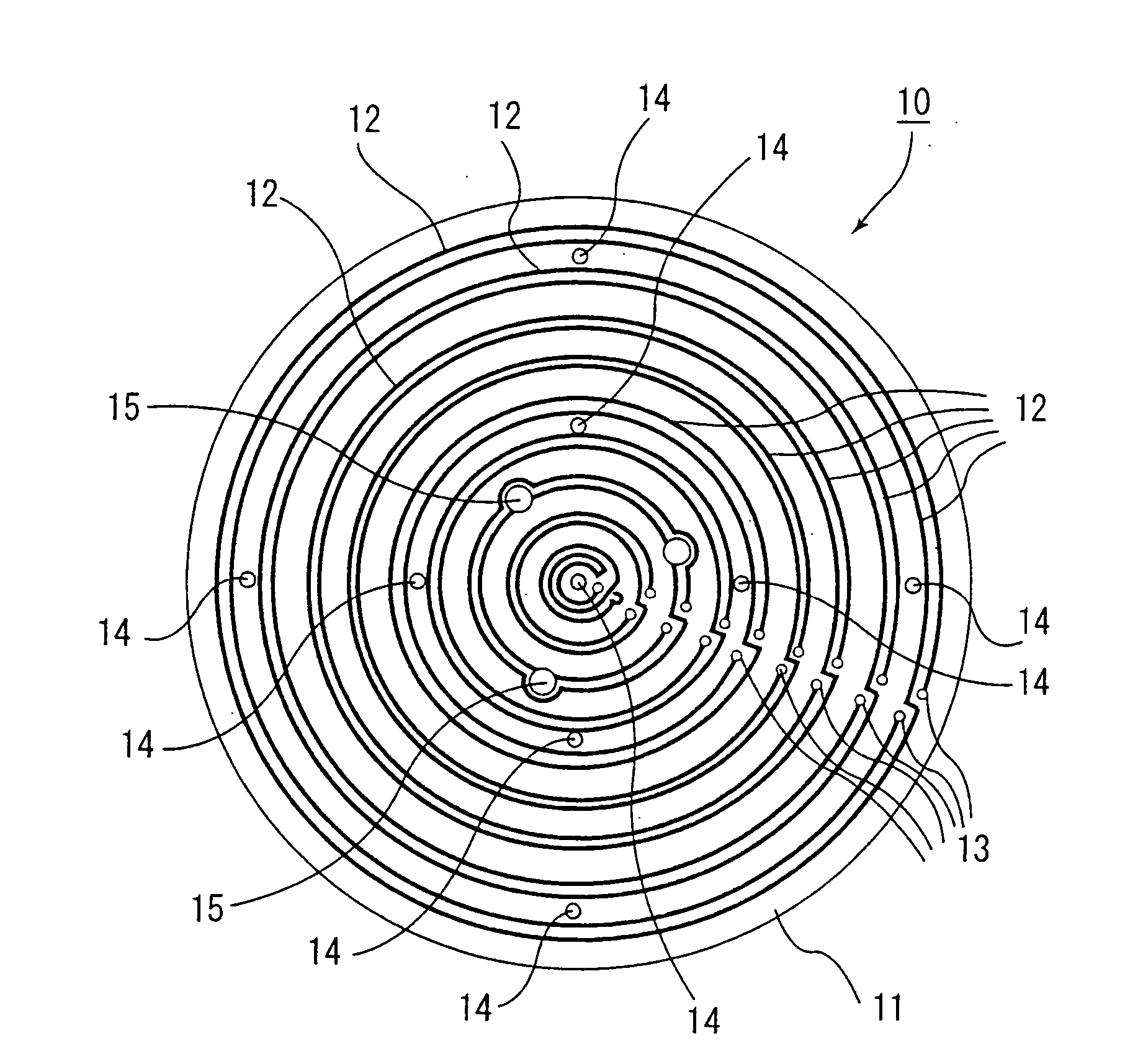

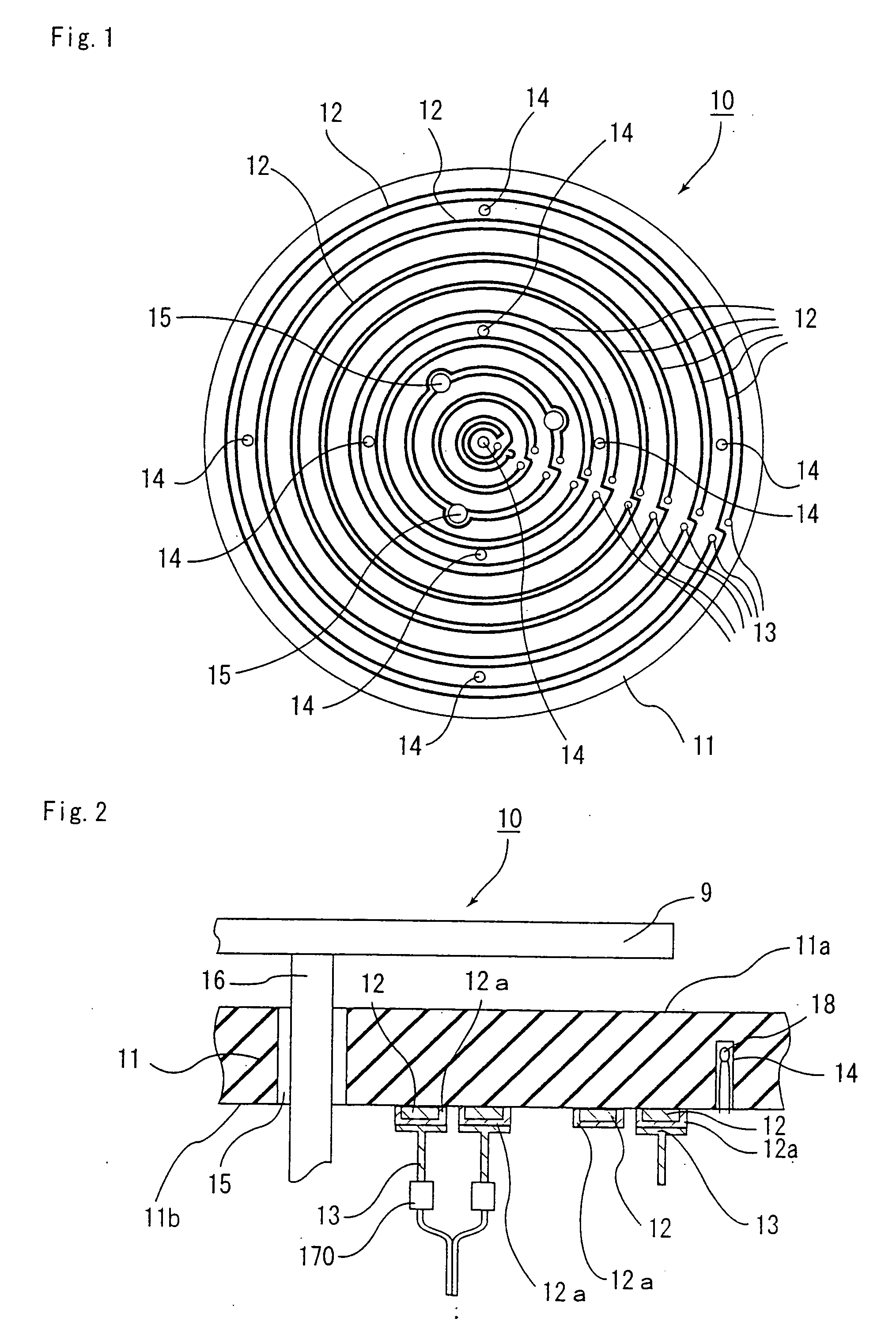

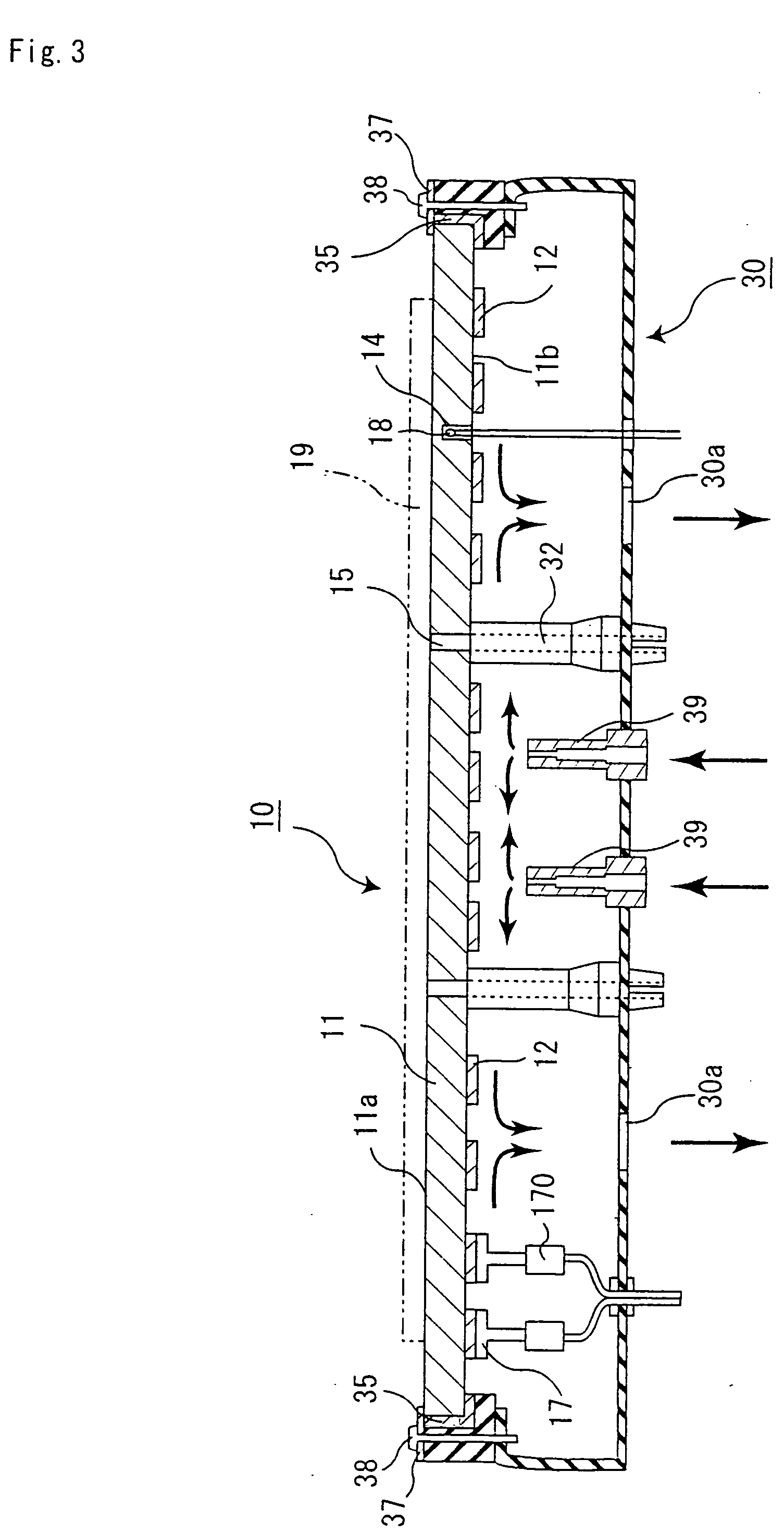

Image

Examples

examples 1 to 7

Manufacture of Hot Plates (Reference to FIG. 6)

[0167] (1) The following paste was used to conduct formation by a doctor blade method to obtain a green sheet 0.47 mm in thickness: a paste obtained by mixing 1000 parts by weight of aluminum nitride powder (made by Tokuyama Corp., average particle diameter: 0.6 μm) fired at 500° C. in the air for 1 hour, 40 parts by weight of yttria (average particle diameter: 0.4 μm), 115 parts by weight of an acrylic binder, 5 parts by weight of a dispersant and 530 parts by weight of alcohols composed of 1-butanol and ethanol.

[0168] (2) Next, this green sheet was dried at 80° C. for 5 hours, and subsequently portions for conductor-filled through holes for connection to external terminals 1.8 mm, 3.0 mm and 5.0 mm in diameter were made by punching.

[0169] (3) The following were mixed to prepare a conductor containing paste A: 100 parts by weight of tungsten carbide particles having an average particle diameter of 1 μm, 3.0 parts by weight of an acr...

example 8

Manufacture of a Hot Plate (Reference to FIG. 5)

[0179] (1) A composition made of 1000 parts by weight of aluminum nitride powder (made by Tokuyama Corp., average particle diameter: 0.6 μm) fired at 500° C. in the air for 1 hour, 40 parts by weight of yttria (Y2O3, average particle diameter: 0.4 μm), 115 parts by weight of an acrylic binder and an alcohol was subjected to spray-drying to make granular powder.

[0180] (2) Next, this granular powder was put into a mold and formed into a flat plate form to obtain a formed body (green). A cool isostatic press (CIP) made of Kobe Steel Ltd. was used to compress this formed body at 300 MPa (3 t / cm2) Thereafter, the surface thereof was ground.

[0181] (3) The raw formed body subjected to the above-mentioned working processing was hot-pressed at 1800° C. and a pressure of 20 MPa to obtain a nitride aluminum sintered body having a thickness of 3 mm.

[0182] Next, this plate was cut out into a disc having a diameter of 230 mm to prepare a plate (...

example 9

[0193] The following paste was used to conduct formation by a doctor blade method to obtain green sheets 0.50 mm in thickness: a paste obtained by mixing 100 parts by weight of silicone nitride powder (made by Tokuyama Corp., average particle diameter: 0.6 μm) fired at 500° C. in the air for 1 hour, 40 parts by weight of yttria (average particle diameter: 0.4 μm), 20 parts by weight of alumina, 40 parts by weight of silica, 11.5 parts by weight of an acrylic binder, 0.5 part by weight of a dispersant and 53 parts by weight of alcohols composed of 1-butanol and ethanol.

[0194] The green sheets were used to produce a lamination in the same way as in Example 1. The lamination was degreased at 600° C. and then compressed at a pressure of 300 MPa (3 t / cm2) by means of a cool isostatic press (CIP) made by Kobe Steel Ltd. Next, the same way as in Example 1 was performed except that firing conditions were made as follows: a temperature of 1900° C. and a pressure of 20 MPa (200 kg / cm2). In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com