Copper conductive slurry and preparation method and application thereof

A technology of conductive paste and paste, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, conductive layers on insulating carriers, etc., can solve the problems of poor performance and high cost of electronic pastes, and achieve high conductivity, Ease of sintering and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

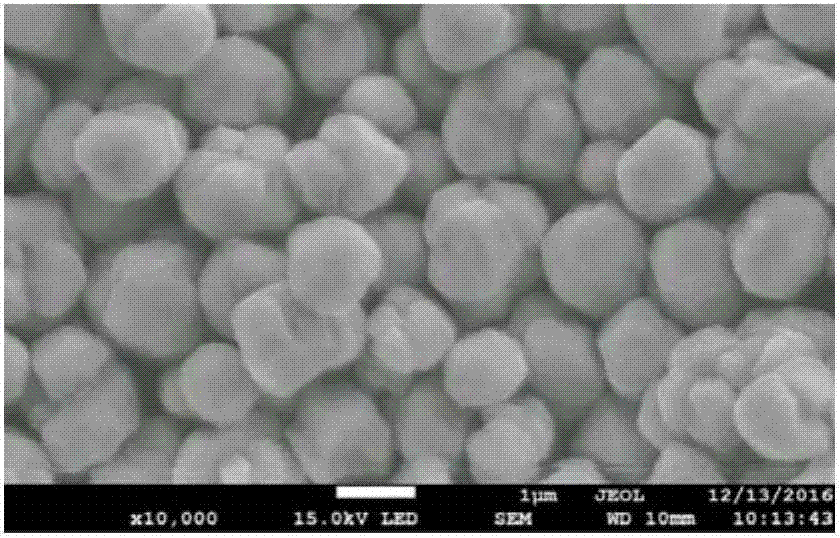

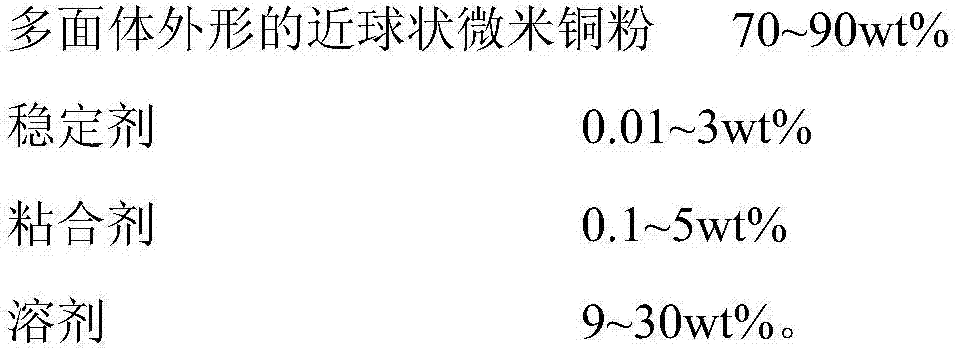

[0036] Weigh 2.5g, 3.5g, and 1g of ethylene glycol ether, diethylene glycol, and glycerin into a beaker, then weigh 0.85g of PVP, 0.8g of ascorbic acid, and stir for 60 minutes with a magnetic stirrer to obtain a uniform solution. Weigh micron copper powder (average particle size 1 μm, polyhedral shape nearly spherical structure) 35g, gradually added to the above solution and stirred, finally obtained a copper slurry with a certain viscosity. The obtained copper slurry was mixed and dispersed on a three-roll mill for 10 minutes to obtain a uniform copper slurry.

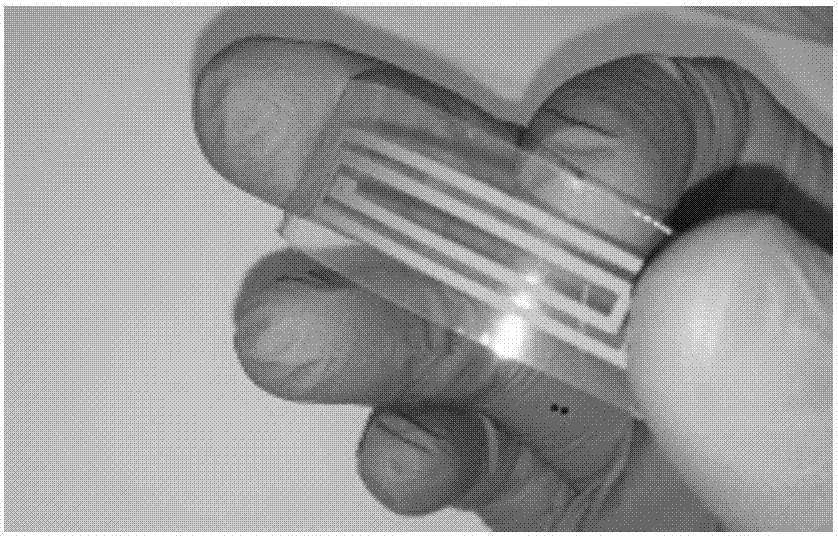

[0037] Copper paste was printed on ordinary copy paper and PET film (Novele TM On IJ-220), the printed pattern is 1mm wide and 150mm long, baked in an oven at 100°C for 20 minutes, and sintered with a pulse xenon lamp. The pulse width is 2ms, three pulses, and the sintering energy is 8J / cm 2 , the test resistance of the paper-based sample is 2.5Ω, the equivalent square resistance is 16.6mΩ / □, and the test resistanc...

Embodiment 2

[0039] Weigh 2.5g, 3.5g, and 1g of ethylene glycol ether, diethylene glycol, and glycerin into a beaker, then weigh 0.8g of PVP, 1.0g of ascorbic acid, and stir for 60 minutes with a magnetic stirrer to obtain a uniform solution. Weigh micron copper powder (average particle size 1 μm, polyhedral shape near spherical structure) 38g, nano copper powder (average particle size 80nm) 2g, after premixing, gradually add to the above solution and stir to finally obtain a copper slurry with a certain viscosity. The obtained copper slurry was mixed and dispersed on a three-roll mill for 10 minutes to obtain a uniform copper slurry.

[0040] Copper paste was printed on ordinary copy paper and PET film (Novele TM IJ-220), the printed pattern is 1mm wide and 150mm long, flash sintering is carried out by pulse xenon lamp, the pulse width is 2ms, three pulses, and the sintering energy is 7.5J / cm 2 , the test resistance of the paper-based sample is 3.2Ω, the equivalent square resistance is ...

Embodiment 3

[0042] Weigh 4.5g, 3.5g, and 1.5g of ethylene glycol ether, diethylene glycol, and glycerin into a beaker, then weigh 1.2g of PVP, 1.0g of ascorbic acid, and stir for 60 minutes with a magnetic stirrer to obtain a uniform solution. Weigh micron copper Powder (average particle size 1 μm, polyhedral shape near spherical structure) 32g, nanometer copper powder (average particle size 80nm) 8g, after premixing, gradually add to the above solution and stir to finally obtain a copper slurry with a certain viscosity. The obtained copper slurry was mixed and dispersed on a three-roll mill for 10 minutes to obtain a uniform copper slurry.

[0043] Copper paste was printed on ordinary copy paper and PET film (Novele TM IJ-220), the printed pattern is 1mm wide and 150mm long, flash sintering is carried out by pulse xenon lamp, the pulse width is 2ms, three pulses, and the sintering energy is 6.8J / cm 2 , the test resistance of the paper-based sample is 3.3Ω, the equivalent square resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com