Preparation method of cuprous sulfide powder, and cuprous sulfide powder

A technology of cuprous sulfide and cuprous oxide, applied in the direction of copper sulfide, etc., can solve the problems of low purity of cuprous sulfide powder, complicated preparation process, no specific shape, etc., and achieve rich and cheap raw materials, simple preparation process, disperse good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

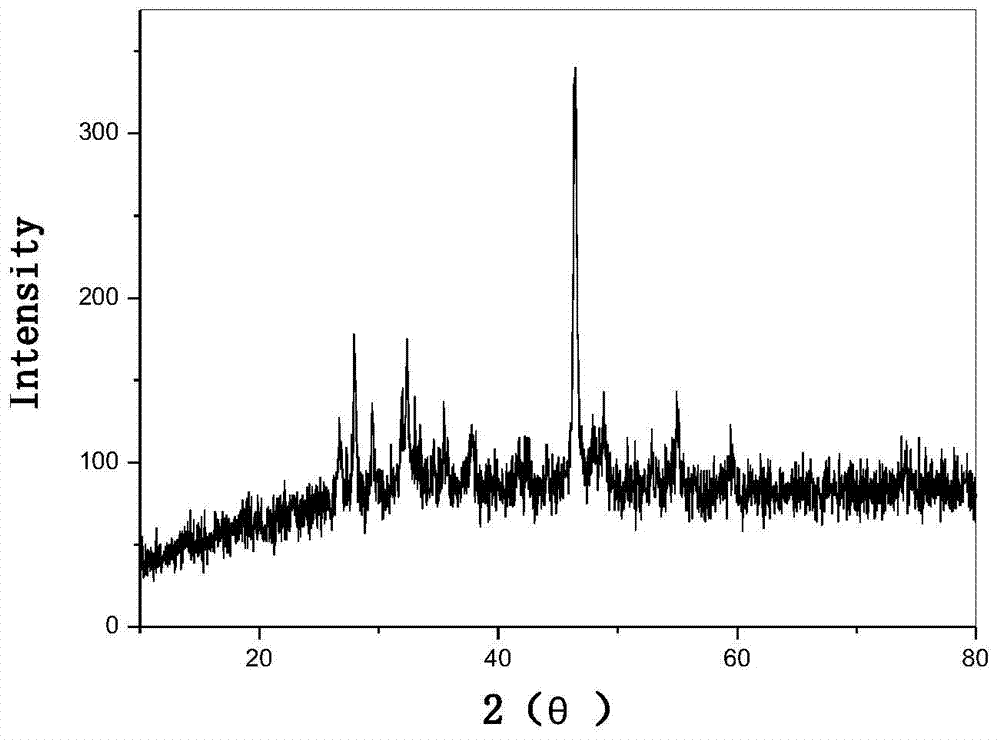

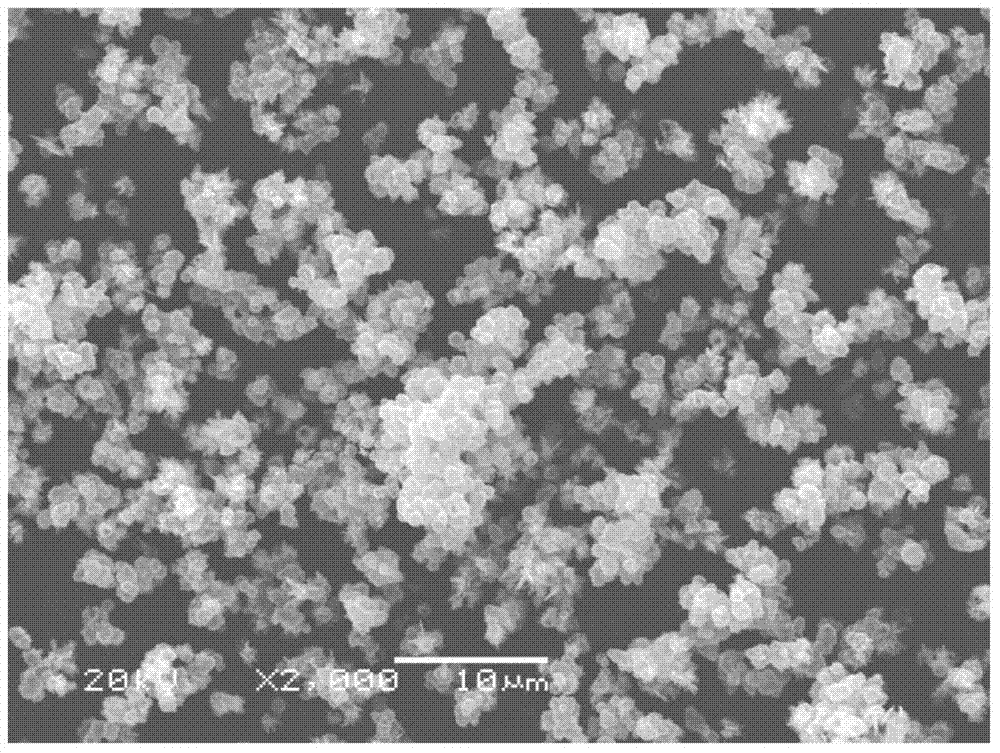

Image

Examples

preparation example Construction

[0025] A preparation method of cuprous sulfide powder, comprising the following steps:

[0026] Step S1: adding soluble divalent copper salt into the alkaline solution to obtain a mixed solution.

[0027] At room temperature, add the soluble divalent copper salt into the alkaline solution, stir and heat until the temperature is 60-80°C. Continue to stir at 60-80°C for 10-30 minutes at a speed of 300r / min.

[0028] Preferably, the soluble divalent copper salt is CuSO 4 and Cu(NO 3 ) 2 at least one of . More preferably, the soluble divalent copper salt is prepared into a solution, and Cu in the divalent copper salt solution 2+ The concentration is 0.5~2mol / L.

[0029] In particular, the alkaline solution is a hydroxide solution. More preferably, the hydroxide is at least one of NaOH and KOH, and OH in alkaline solution - The concentration is 1~4mol / L.

[0030] In particular, the pH of the mixed liquid is 9-14.

[0031] In this step, Cu 2+ React with alkaline solution ...

Embodiment 1

[0062] At room temperature, 25 g of CuSO 4 ﹒ 5H 2 Dissolve O in water to prepare a 0.5mol / L copper sulfate solution, add 4mol / L NaOH solution until the pH of the mixture is 14, and heat to 80°C for 30 minutes under stirring at a rotating speed of 300r / min to obtain a precipitate containing Mixed solution; continue to add 40g of glucose, and react for 1 hour under stirring at a rotating speed of 300r / min, then add 5ml of polyethylene glycol 2000 aqueous solution with a mass fraction of 10%, and react for 0.5 hour under stirring at a rotating speed of 300r / min, Centrifuge to obtain cuprous oxide slurry.

[0063] 20.4g of (NH 4 )SH was dissolved in 0.05 mol / L NaOH solution, 5 ml of hydrazine hydrate with a mass fraction of 1% was added, and stirred for 10 minutes to obtain a vulcanizing agent solution.

[0064] Mix the cuprous oxide slurry with the vulcanizing agent solution, and react for 1 hour under stirring at a rotating speed of 300 r / min to prepare a cuprous sulfide pre...

Embodiment 2

[0067] At room temperature, 25 g of CuSO 4 ﹒ 5H 2 O was dissolved in water to prepare a 1mol / L copper sulfate solution, and 3mol / L NaOH solution was added until the pH of the mixed solution was 12. Under stirring at a speed of 300r / min, it was heated to 80°C for 30 minutes to obtain a precipitate containing Mixed solution; continue to add 40g of glucose, and react for 1 hour under stirring at a rotating speed of 300r / min to obtain a mixed solution containing cuprous oxide; then add 5ml of a 5% polyethylene glycol 2000 aqueous solution with a mass fraction of 300r / min / min under stirring for 0.5 hours, centrifuged to obtain cuprous oxide slurry.

[0068] 20.4g of (NH 4 )SH was dissolved in 0.05 mol / L NaOH solution, 5 ml of hydrazine hydrate with a mass fraction of 1% was added, and stirred for 10 minutes to obtain a vulcanizing agent solution.

[0069] Mix the cuprous oxide slurry with the vulcanizing agent solution, and react for 1 hour under stirring at a rotation speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com