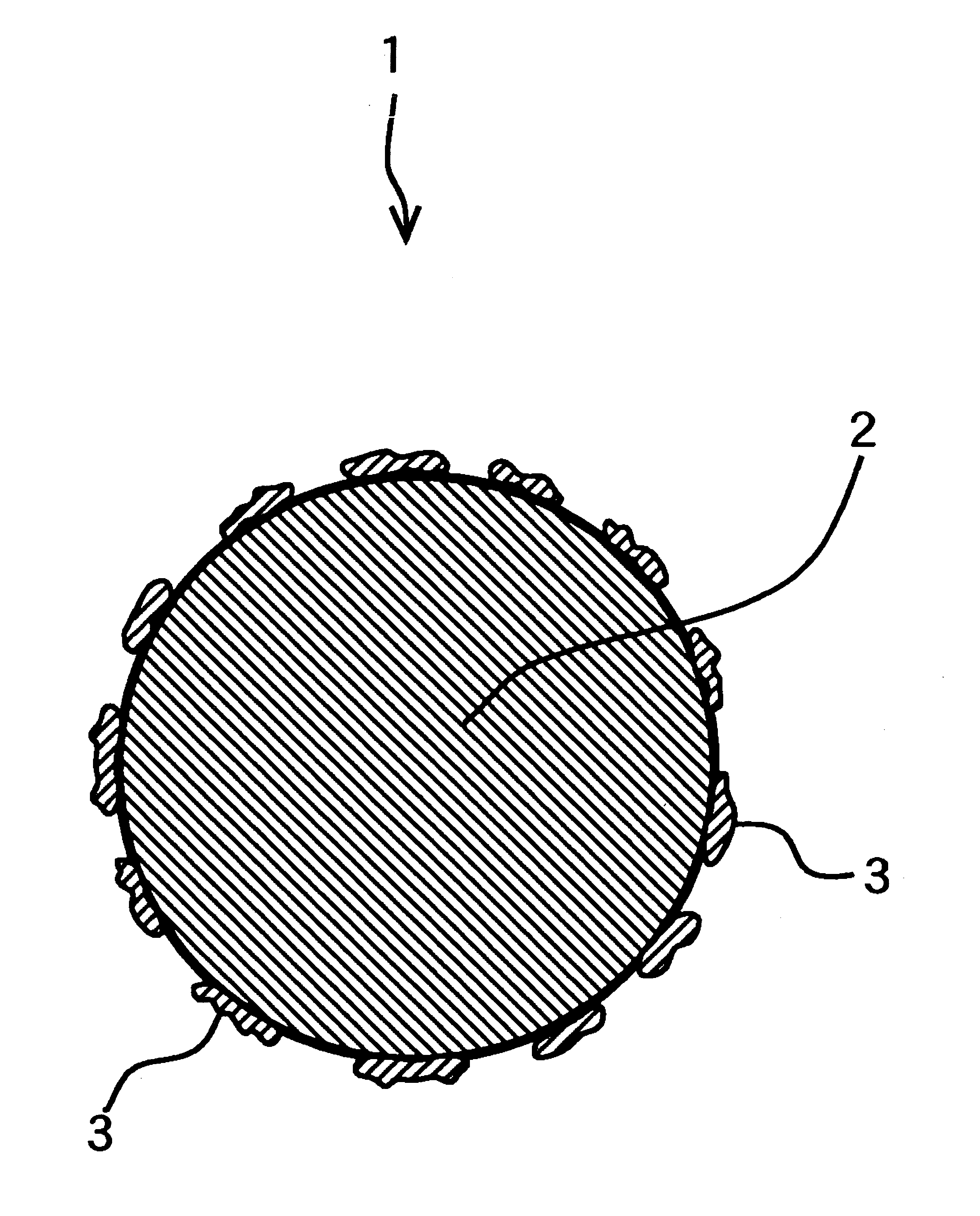

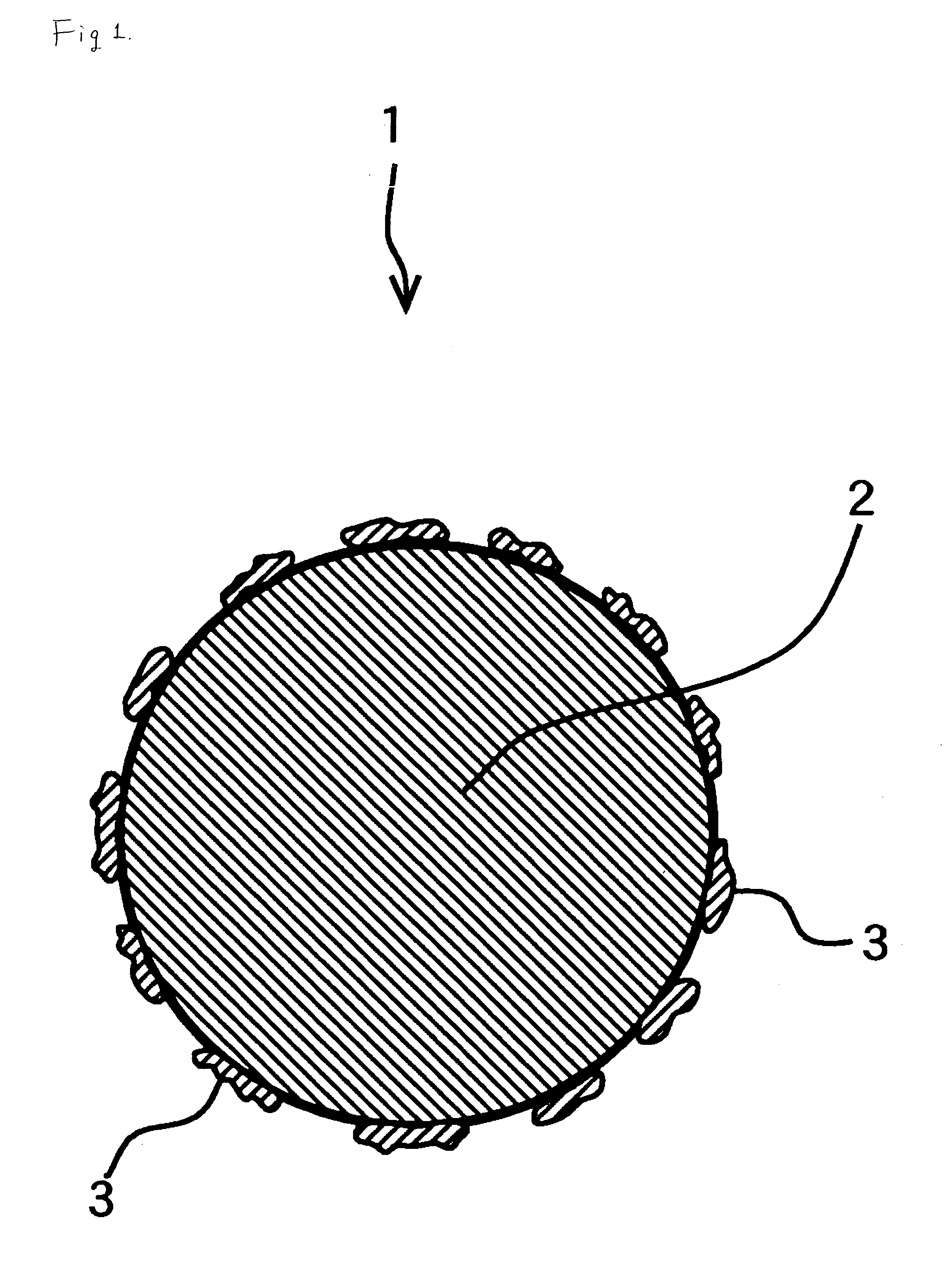

Silver powder made of silver particles, each to which fine silver particles adhere and process of producing the same

a silver nanoparticle and silver powder technology, applied in the direction of printed circuit aspects, semiconductor/solid-state device details, transportation and packaging, etc., can solve the problem of difficult to meet the size-refinement of powder particles and the dispersibility meant by powder particles nearly in a mono-disperse state, and the low-temperature sintering performance of silver nanoparticles cannot be used to the full, so as to reduce the amount of impurities contained, improve the effect of low-temperature sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Process for Producing Silver Powder Used as a Core Material:

[0068] In this example, first silver powder (whose particle is spherical) used as a core material was produced. The production process was as follows.

[0069] First, 63.3 g of silver nitrate was dissolved in 9.7 liter of deionized water to prepare an aqueous solution of silver nitrate. Then, 235 ml of 25% by weight aqueous ammonia was added for a very short time to the aqueous solution of silver nitrate and stirred to give an aqueous solution of a silver ammine complex.

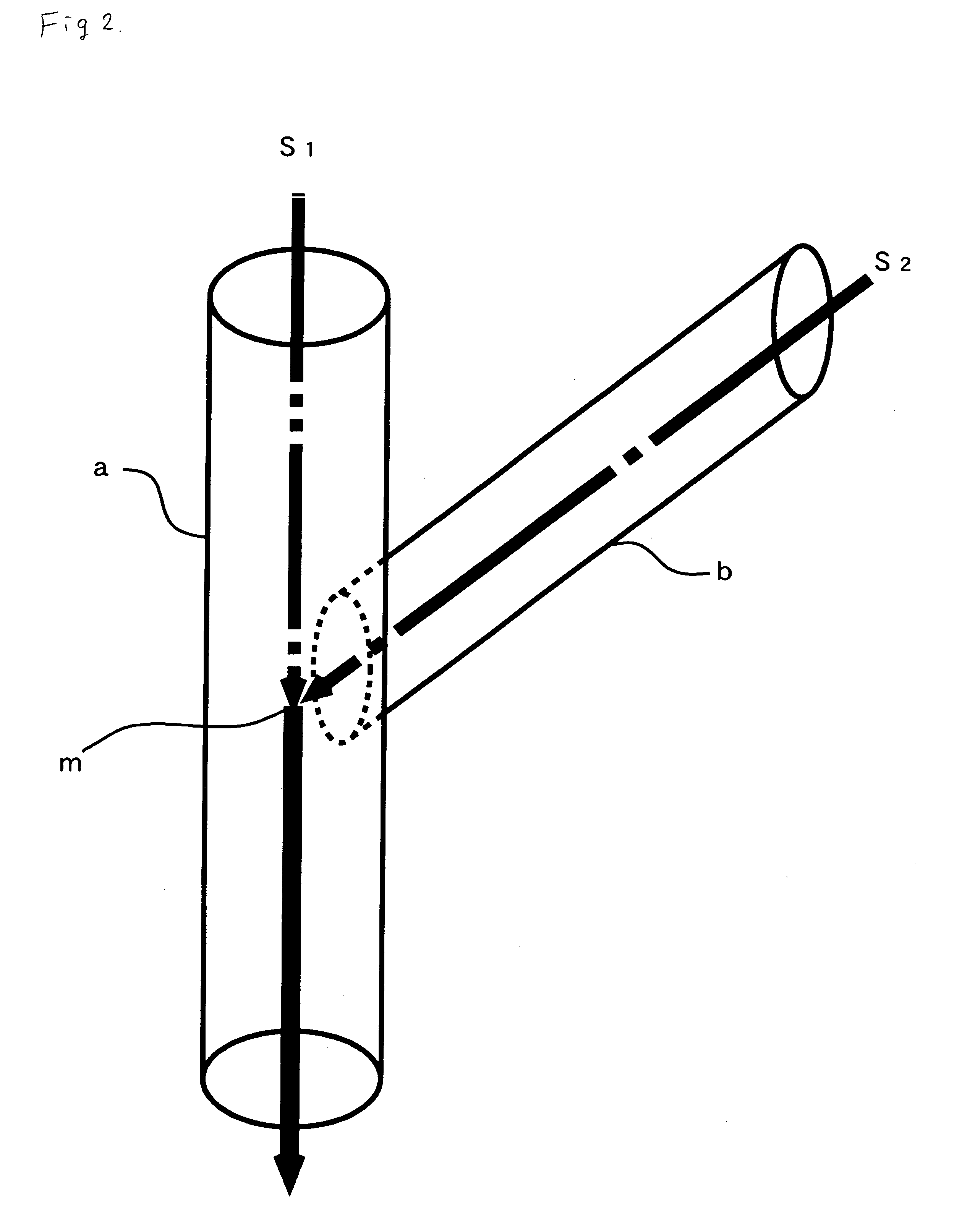

[0070] The aqueous solution of a silver ammine complex was introduced into a first pass a having an inner diameter 13 mm, shown in FIG. 2, at a flow rate of 1500 ml / sec and a reducing agent was allowed to flow through a second pass b at a flow rate of 1500 ml / sec so that the solution and the agent came into contact with each other at a juncture m while being kept at 20° C. to precipitate fine silver powder through reduction. The reduction agent used here wa...

example 2

Process for Producing Silver Powder Used as a Core Material:

[0077] In this example, first silver powder (which is substantially spherical) used as a core material was produced. The production conditions were as described below.

[0078] Silver powder was produced under production conditions different from those of Example 1 and the powder characteristics of the resultant silver powder were determined. Then, a silver paste was prepared using the above silver powder and a test circuit was formed using the silver paste. Then, the specific resistance of the conductor and sinterable temperature were measured for the formed test circuit.

[0079] First, 63.3 g of silver nitrate was dissolved in 3.1 liter of deionized water to prepare an aqueous solution of silver nitrate. Then, 235 ml of 25% by weight aqueous ammonia was added for a very short time to the aqueous solution of silver nitrate and stirred to give an aqueous solution of a silver ammine complex.

[0080] The aqueous solution of a s...

example 3

Process for Producing Silver Powder Used as a Core Material:

[0087] In this example, first silver powder (of nearly spherical shape) having a large crystallite size was produced using the process shown below, and the powder characteristics of the resultant silver powder were determined. Then, a silver paste was prepared using the above silver powder and a test circuit was formed using the silver paste. Then the specific resistance and sinterable temperature were measured for the formed test circuit.

[0088] First, 20 g of polyvinyl pyrrolidone was dissolved in 260 ml of deionized water and 50 g of silver nitrate was dissolved to prepare an aqueous solution of silver nitrate. Then, 25 g of nitric acid was added for a very short time to the above solution and stirred to yield a silver-containing nitric acid solution. At the time of completion of the mixing, the concentration of ascorbic acid was about 36.0 g / l.

[0089] A reducing solution was prepared by adding and dissolving 35.8 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystallite size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com