Piezoceramic material and preparation method thereof

A technology of piezoelectric ceramics and raw materials, applied in the field of piezoelectric ceramics materials and their preparation, can solve the problems of low dielectric constant, high mechanical quality factor and electromechanical coupling coefficient, and achieve the effect of low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

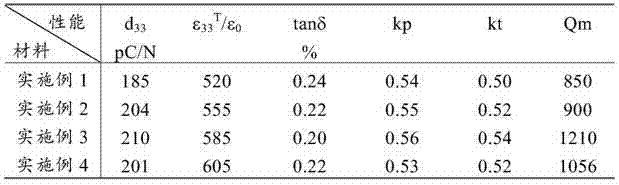

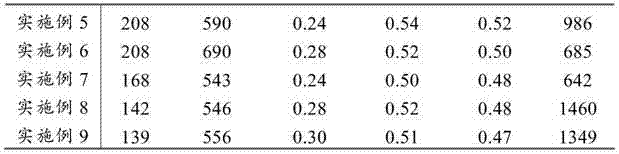

Examples

Embodiment 1

[0026] Pb 0.93 Sr 0.02 Ba 0.05 (Sb 1 / 2 Nb 1 / 2 ) 0.01 (Mn 1 / 3 Sb 2 / 3 ) 0.02 (Zr 0.545 Ti 0.455 ) 0.97 o 3 +0.02wt.%Fe 2 o 3 +0.1wt.%Sm 2 o 3 +0.06wt.%MnO 2 +0.01wt.%Al 2 o 3 piezoelectric ceramic material

[0027] First weigh Pb according to the stoichiometric ratio 3 o 4 , ZrO 2 、TiO 2 , SrCO 3 、BaCO 3 , MnCO 3 、Sm 2 o 3 , Sb 2 o 3 , Fe 2 o 3 , Nb 2 o 5 and Al 2 o 3 The raw material powder was barrel-milled for 6 hours by a wet ball milling process to obtain a ball mill mixture, wherein the mass ratio of raw material powder:steel ball:deionized water was 1:1.5:0.8. After the ball mill mixture was dried, it was briquetted, then synthesized at 650°C for 2 hours, and then heated to 850°C for 2 hours. After pulverizing, use the wet ball milling process to finely grind the barrel for 24 hours, wherein the mass ratio of raw material powder: steel balls: deionized water is 1:2:0.6, and after drying, add 6wt% of the raw material powder by weight Th...

Embodiment 2

[0029] Pb 0.93 Sr 0.02 Ba 0.05 (Sb 1 / 2 Nb 1 / 2 ) 0.005 (Mn 1 / 3 Sb 2 / 3 ) 0.015 (Zr 0.545 Ti 0.455 ) 0.98 o 3 +0.02wt.%Fe 2 o 3 +0.1wt.%Sm 2 o 3 +0.06wt.%MnO 2 +0.01wt.%Al 2 o 3 piezoelectric ceramic material

[0030] Weigh according to stoichiometric ratio, preparation process is the same as embodiment 1.

Embodiment 3

[0032] Pb 0.93 Sr 0.02 Ba 0.05 (Sb 1 / 2 Nb 1 / 2 ) 0.01 (Mn 1 / 3 Sb 2 / 3 ) 0.02 (Zr 0.545 Ti 0.455 ) 0.97 o 3 +0.02wt.%Fe 2 o 3 +0.1wt.%Sm 2 o 3 +0.05wt.%MnO 2 +0.01wt.%Al 2 o 3 piezoelectric ceramic material

[0033] Weigh according to stoichiometric ratio, preparation process is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com