Surface acoustic wave device and electronic apparatus

a surface acoustic wave and electrode technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostriction/magnetostriction machines, electrical apparatus, etc., can solve the problems of difficult to achieve higher frequencies for surface acoustic wave devices using reflection/inversion type idt electrodes, and achieve excellent frequency temperature characteristics, small frequency variation, and easy to achieve higher frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

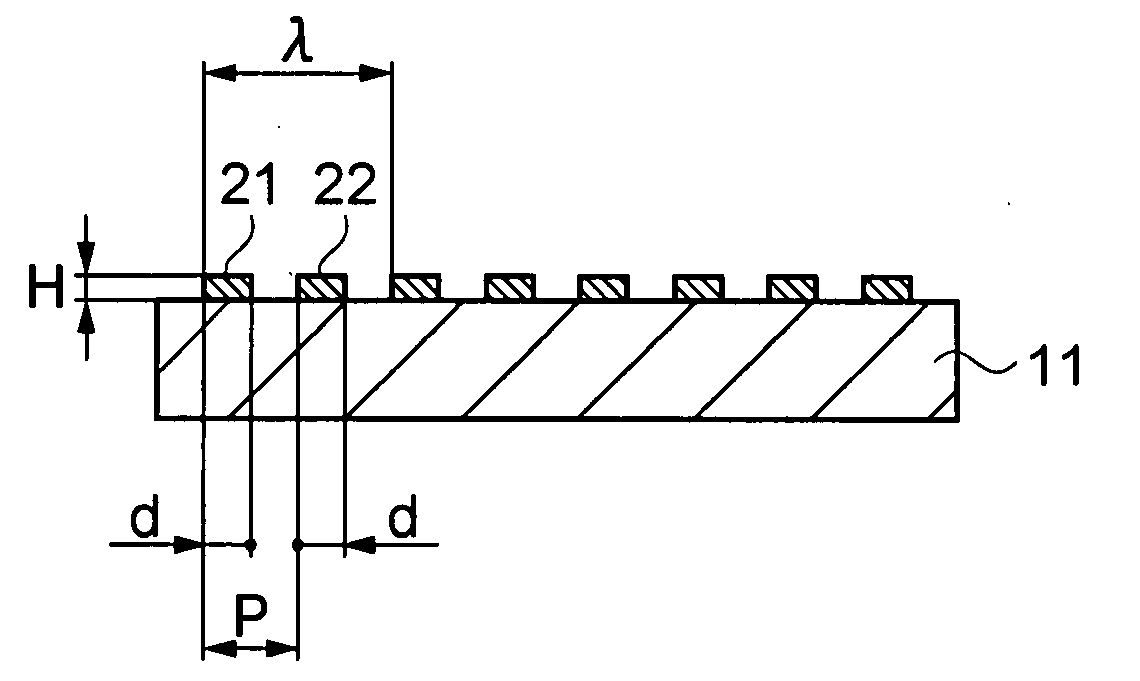

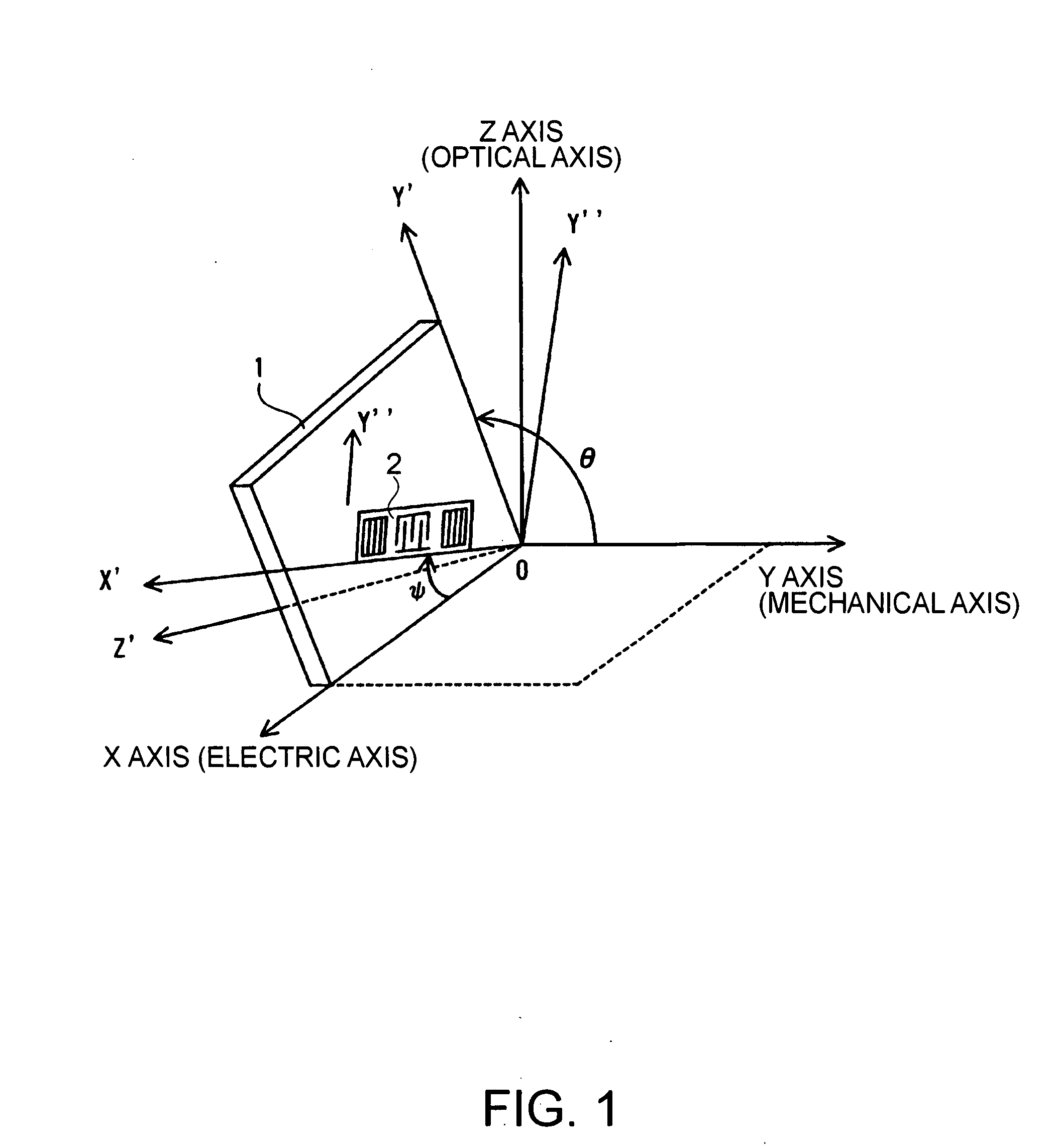

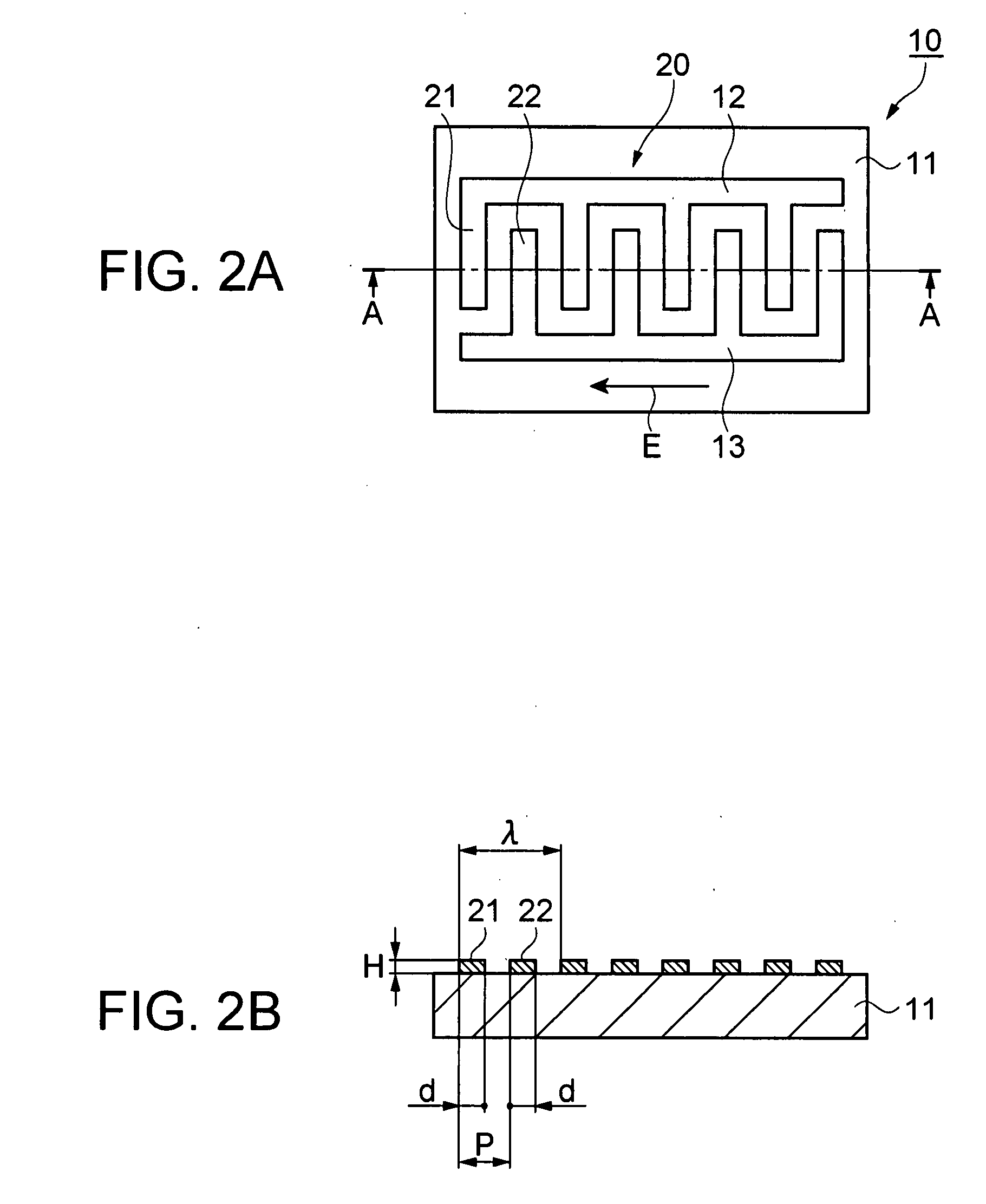

[0033]An embodiment of the invention will now be described with an SAW resonator as an example of a surface acoustic wave device. FIGS. 2A and 2B are schematic views of an SAW resonator including a single-type IDT electrode and serving as a surface acoustic wave device. FIG. 2A is a schematic plan view of the SAW resonator, and FIG. 2B is a schematic sectional view taken along line A-A of FIG. 2A.

[0034]A SAW resonator 10 has an IDT electrode 20 provided on a surface of a quartz substrate 11. The IDT electrode 20 includes an electrode 12 having multiple electrode fingers 21 and an electrode 13 having multiple electrode fingers 22. The electrode fingers 21 and 22 are disposed as if to be engaged with each other, and are formed with a thickness H and an electrode width d. Pitches P between the electrode fingers 21 and 22 are continuously formed in equal lengths. One electrode finger 21 and one electrode finger 22 are provided in one wavelength λ of a surface acoustic wave. The IDT elec...

second embodiment

[0053]Now a second embodiment will be described using as an example an SAW resonator including a reflector on both sides of the single-type IDT electrode described in the first embodiment. Generally, in a surface acoustic wave resonator, surface acoustic waves propagated outward of the IDT electrode are reflected off the reflector so as to trap the surface acoustic wave energy in the IDT electrode section. This makes it possible to obtain a less energy loss resonance characteristic.

[0054]FIGS. 6A and 6B are schematic views of the SAW resonator including the single-type IDT electrode and serving as a surface acoustic wave device; FIG. 6A is a schematic plan view of the SAW resonator, and FIG. 6B is a schematic sectional view taken along line B-B of FIG. 6A. In FIGS. 6A and 6B, the same elements as shown in FIG. 2 are given the same reference numbers.

[0055]The SAW resonator 10 has the IDT electrode 20 provided on a surface of the quartz substrate 11 and reflectors 14 and 15 on the sid...

third embodiment

[0064]FIG. 9 is a partial sectional view of an embodiment in which the SAW resonator serving as a surface acoustic wave device described in the first or second embodiment is packaged. An SAW resonator 31 is housed in a container 36 in such a manner that the SAW resonator 31 is fixed to the inside of the container 36. On the SAW resonator 31, a single-type IDT electrode 32 and a connection pad 33 to be connected to the single-type IDT electrode 32 are formed. The connection pad 33 on the SAW resonator 31 is electrically connected to a connection terminal 35 formed in the container 36 via a wire 34 made of Au. A lid 37 is put on the container 36 to keep the interior of the container 36 in a pressured-reduced atmosphere or an inert gas atmosphere. Thus, a packaged SAW resonator 30 is configured.

[0065]As described above, according to this embodiment, it is possible to obtain the packaged SAW resonator 30 that uses the single-type IDT electrode and utilizes the upper limit mode of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com