White-resistant pulp used for physical reserve printing by reactive dye

A reactive dye and anti-white technology, applied in the field of textile printing and dyeing, can solve the problems of poor anti-printing effect, unclean anti-printing, and too high dosage, and achieve the effect of improving softness, increasing stability and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

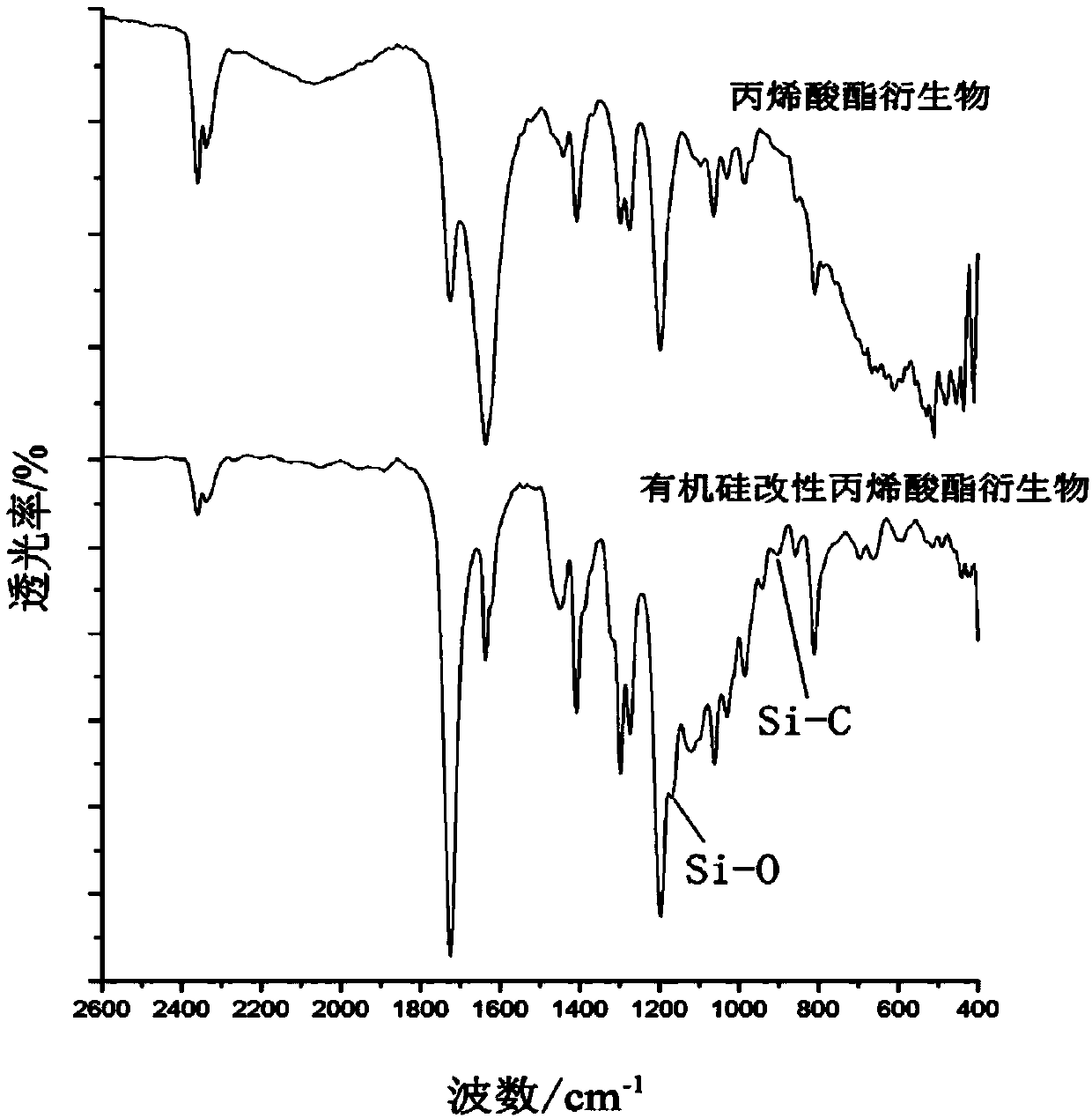

[0026] Preparation of silicone-modified acrylate derivative adhesive: add 20g of butyl acrylate, 2g of methyl methacrylate, 2g of methacrylic acid mixed monomer and 0.5g of silicone coupling agent KH570 into the reactor, Add 0.1g of ammonium persulfate initiator, start the agitator, heat up to 60°C, and keep warm for 30min; then add 0.1g of ammonium persulfate initiator, keep the reaction temperature at 60°C; heat up to 75°C, and react at constant temperature for 60min; after the reaction, After cooling down to room temperature, adjust the pH of the emulsion to 8.0 with ammonia water, then stop stirring, discharge, and store for future use.

[0027] From the comparative analysis of infrared spectra of acrylate derivatives and silicone-modified acrylate derivatives, see figure 1 ; It can be seen that the newly-appeared 943cm in the modified infrared spectrum -1 Si-CH 3 The characteristic absorption peak of 1169cm -1 It is the characteristic absorption peak of Si-O-Si bond, a...

Embodiment 2

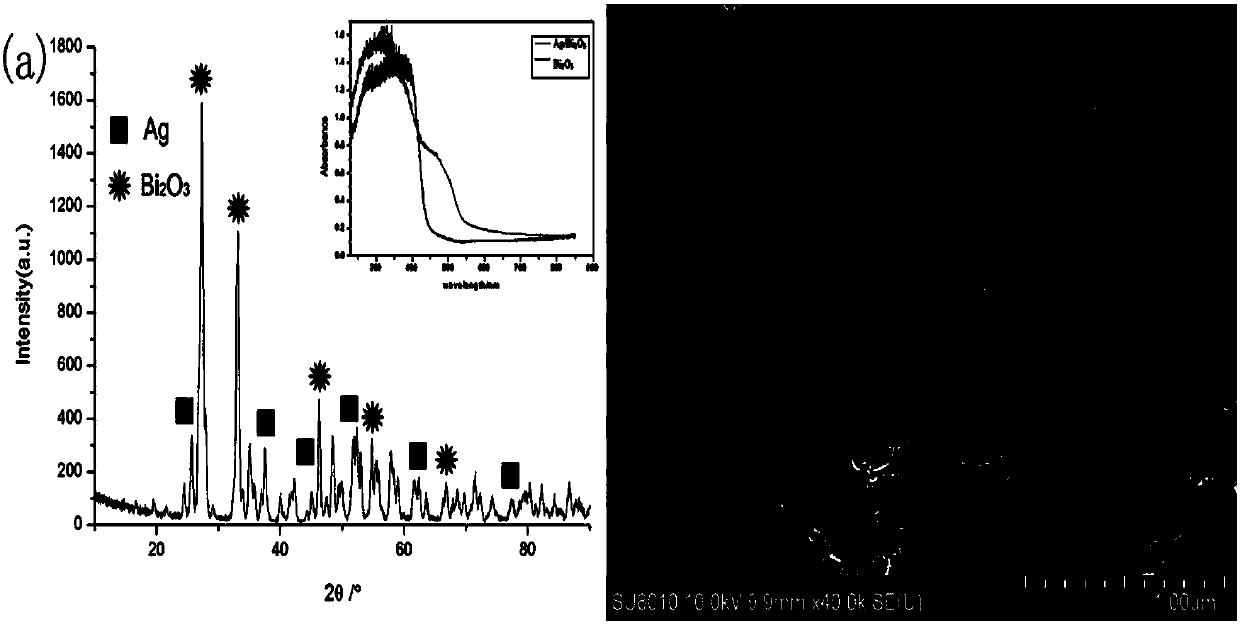

[0032] Ag / Bi Added to Silicone-Modified Acrylate Derivatives with Photosensitive Properties 2 o 3 Preparation of photocatalyst: weigh 1.5gAgNO 3 Put into 30mL deionized water, stir to dissolve, then add 2.8gNaBiO 3 Stir to mix evenly, add the prepared reaction solution into a hydrothermal reaction kettle with a polytetrafluoroethylene lining, put the reaction kettle into a blast drying oven, and react at 150°C for 5 hours; after the reaction is completed, take it out naturally Cool to room temperature, suction filter the obtained suspension, wash twice with 20mL deionized water and 20mL absolute ethanol, and dry at 100°C for 5h to obtain the precursor; put the precursor in a mortar and grind repeatedly Place the ark in a 30mm×60mm ark, put it into a muffle furnace, and calcinate it at 500°C for 4 hours. After the reaction is over, cool it down to room temperature naturally to get Ag / Bi 2 o 3 , save for later use.

[0033] Ag / Bi 2 o 3 XRD patterns of photocatalysts, see ...

Embodiment 3

[0037] The preparation method of the anti-white paste of physical anti-printing reactive dyes comprises the following steps.

[0038] Step 1. Preparation of citric acid-sodium trichloroacetate aqueous solution: add 1 g of citric acid and 3 g of sodium trichloroacetate to 50 g of deionized water, adjust the pH to 6.5, and set aside.

[0039] Step 2, the processing of acid printing paste: the citric acid-sodium trichloroacetate aqueous solution of step 1 is placed in the beaker and is heated to 65 ℃; With 4.4g sodium alginate, 0.4g chitosan, 0.2g glacial acetic acid (mass The ratio is 22:2:1) and 0.5g fatty alcohol polyoxyethylene ether, then add it into the citric acid-sodium trichloroacetate aqueous solution three times on average, keep stirring at 65°C for 20-30min, and it becomes a translucent paste (viscosity 30000Pa.s), save it for future use.

[0040] Step 3, preparation of photosensitive silicone-modified acrylate derivative adhesive: add 20g of butyl acrylate, 2g of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com