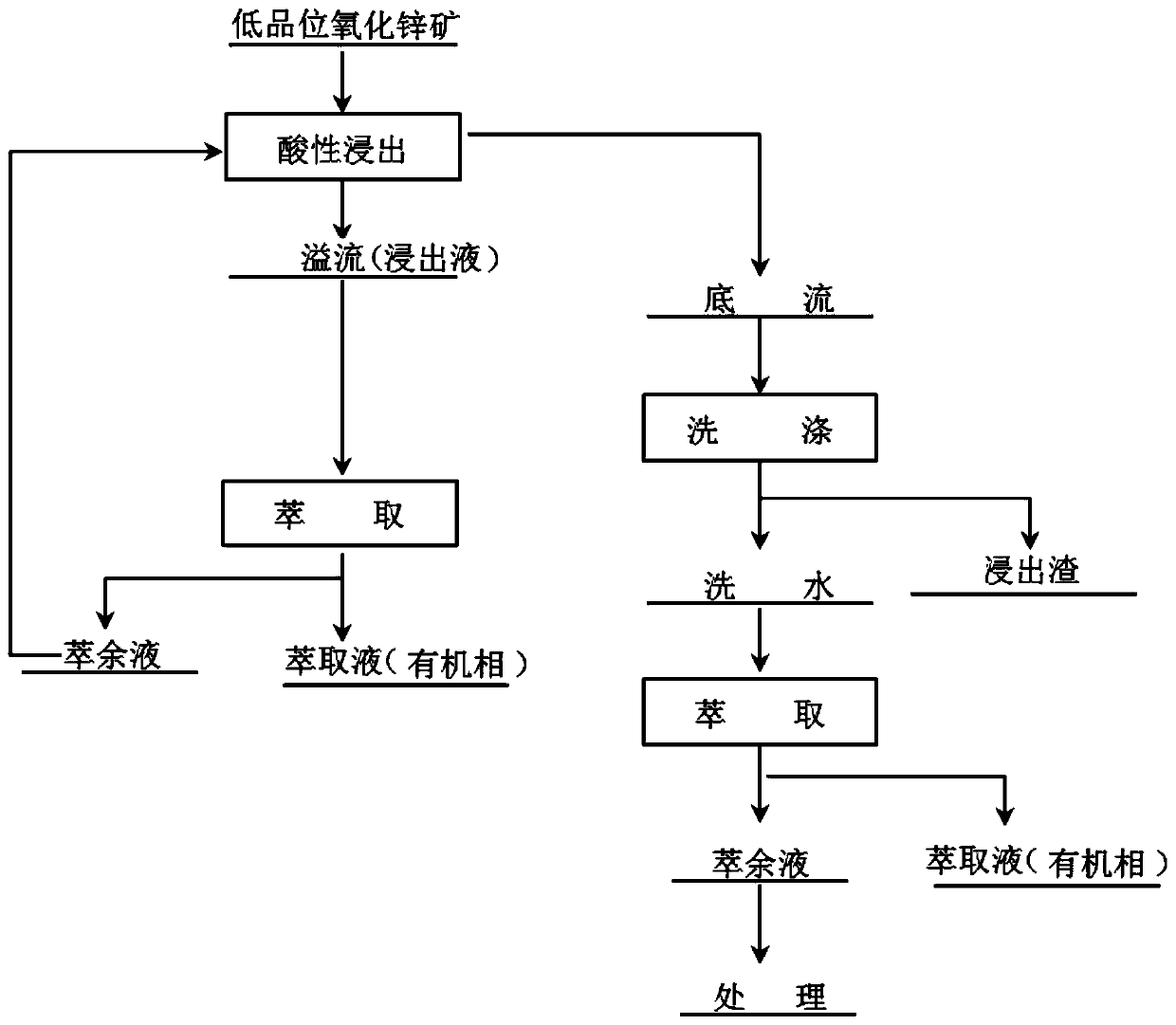

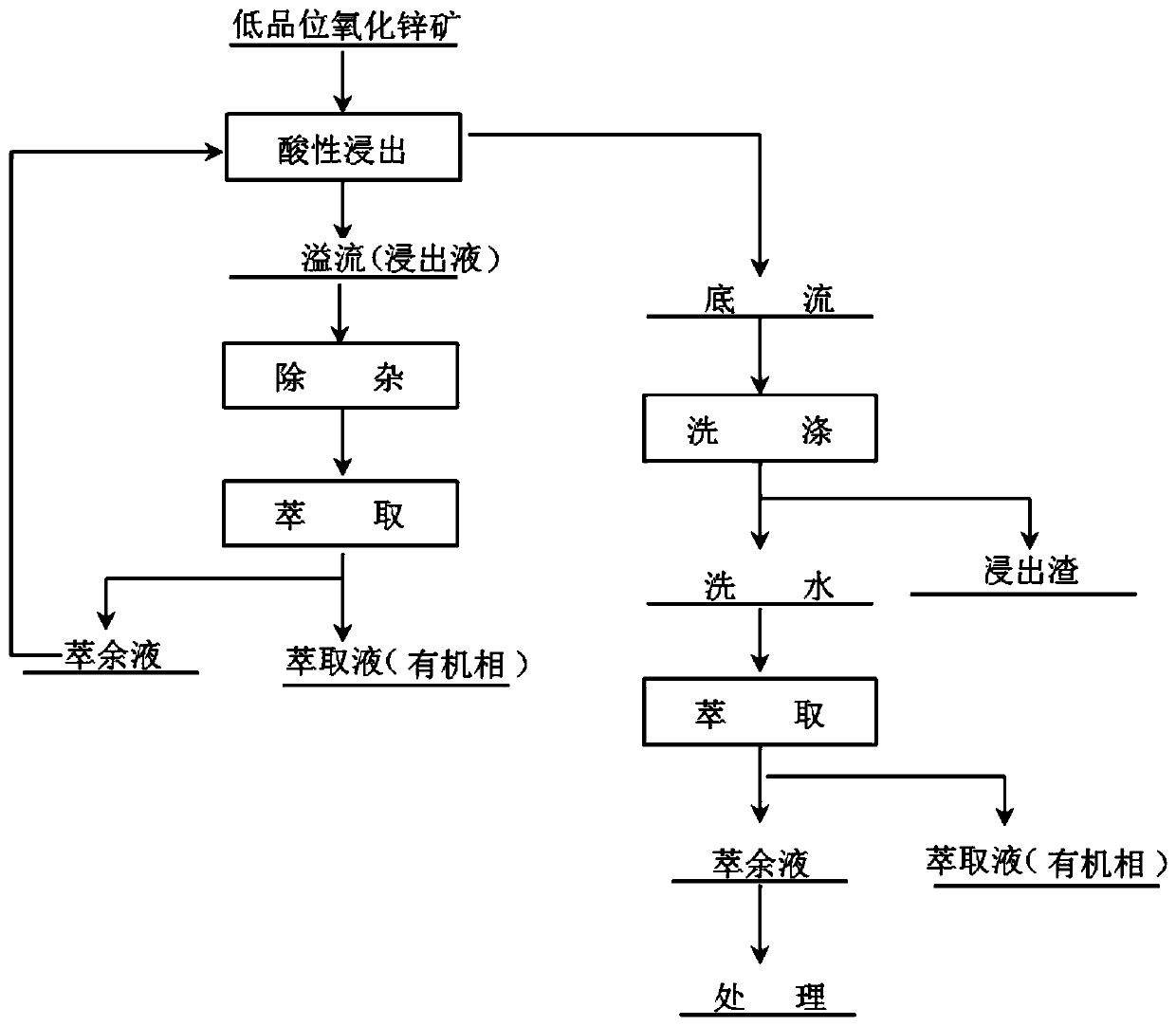

Low-grade zinc oxide extraction method

An extraction method and zinc oxide technology, applied in the field of ore smelting, can solve the problems of inability to carry out electrowinning recovery, high impurity content, low zinc concentration, etc., and achieve the effects of low cost, high metal recovery rate and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Leaching treatment:

[0034] The low-grade zinc oxide ore was leached with 0.61mol / L sulfuric acid. The liquid-solid ratio in the leaching treatment was 4:1, the leaching temperature was 30°C, the leaching time was 3.5h, the amount of sulfuric acid was 241kg / t, and the final pH value was 1.95. In the immersion solution, the concentration of zinc is 32.94g / L, and the leaching rate is 94.24%; the concentration of iron is 0.558g / L, and the leaching rate is 4.42%; the concentration of aluminum is 0.8g / L, and the leaching rate is 7.5%. ; The concentration of silica is 0.476g / L, and the leaching rate is 4.2%.

[0035] (2) The leaching solution is stirred with air at 70°C, the stirring speed is 700 rpm, and the pH value is 3.8 to 4.5. After removing metal impurities such as Fe and Ni under the above conditions, the leaching solution is extracted with P204 to obtain Zn. The leaching solution was extracted, the extraction rate of Zn was 53.23wt%, and the recovery rate of Zn...

Embodiment 2

[0037] The difference from Example 1 is: the consumption of sulfuric acid corresponding to each ton of low-grade zinc oxide is 270Kg, the liquid-solid ratio of low-grade zinc oxide and the leaching process is 2:1, and the endpoint pH value of the leaching solution is 1.74.

[0038] In the immersion solution, the concentration of zinc element is 30.95g / L, and the leaching rate is 92.57wt%; the concentration of iron element is 1.845g / L, and the leaching rate is 7.3wt%; the concentration of aluminum element is 1.424g / L, and the leaching rate is 1.424g / L. 13.35wt%; the concentration of silica is 0.629g / L, and the leaching rate is 5.55wt%.

[0039] The extraction rate of Zn from the leaching solution was 53.23wt%, and the recovery rate of Zn was 90.97wt%.

Embodiment 3

[0041] The difference from Example 1 is that the endpoint pH value of the leachate is adjusted to 5.

[0042]In the leaching solution, the concentration of zinc element is 29.64.g / L, the leaching rate is 88.44wt%; the concentration of iron element is 1.345g / L, the leaching rate is 5.32wt%; the concentration of aluminum element is 1.425g / L, the leaching rate is 13.36wt%; the concentration of silica is 0.473g / L, and the leaching rate is 4.00wt%.

[0043] The extraction rate of Zn from the leaching solution was 54.49wt%, and the recovery rate of Zn was 86.84wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com