Negative ion composite powder suitable for building materials

A technology of composite powder and negative ions, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low concentration of negative ions, poor efficacy and durability, etc., achieve low prices, purify the air, and eliminate indoor odors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

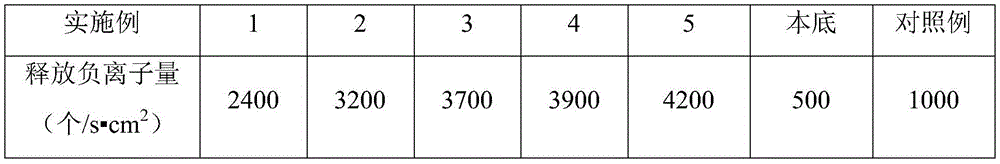

Examples

Embodiment example 1

[0022] Weigh 30 parts of black tourmaline powder with a particle size of 30 μm, 20 parts of red zinc mineral powder with a particle size of 40 μm, and 1 part of water-based acrylic acid. Take 1 part of calcium stearate, 1 part of zinc oxide, 1 part of cerium oxide, 1 part of ferric oxide, 1 part of monazite powder, and 1-8 parts of sodium hexametaphosphate, and mix them evenly through a dry powder mixer to obtain negative Oxygen ion composite powder.

Embodiment example 2

[0024] Weigh 80 parts of black tourmaline powder with a particle size of 20 μm, 40 parts of red zinc ore powder with a particle size of 25 μm, and 8 parts of water-based acrylic acid. Take 8 parts of calcium stearate, 5 parts of zinc oxide, 8 parts of cerium oxide, 30 parts of rare earth, 30 parts of ferric oxide, 8 parts of monazite powder, and 8 parts of sodium hexametaphosphate, and mix them evenly through a dry powder mixer. Obtain negative oxygen ion composite powder.

Embodiment example 3

[0026] Weigh 40 parts of black tourmaline powder with a particle size of 10 μm, 30 parts of red zinc ore powder with a particle size of 15 μm, and 4 parts of water-based acrylic acid, add an appropriate amount of water, and bathe at 90 ° C for 1 hour, filter, dry, break up, weigh Take 4 parts of calcium stearate, 3 parts of zinc oxide, 4 parts of cerium oxide, 16 parts of rare earth, 15 parts of ferric oxide, 5 parts of monazite powder, and 5 parts of sodium hexametaphosphate, and mix them evenly through a dry powder mixer. Obtain negative oxygen ion composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com