Method for producing high purity metal zinc from zinc oxide ore

A technology of zinc oxide ore and metal zinc, applied in the direction of improving process efficiency, etc., can solve the problems of low total recovery rate of zinc, environmental pollution, waste of resources, etc., achieve low price, good economic and social benefits, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

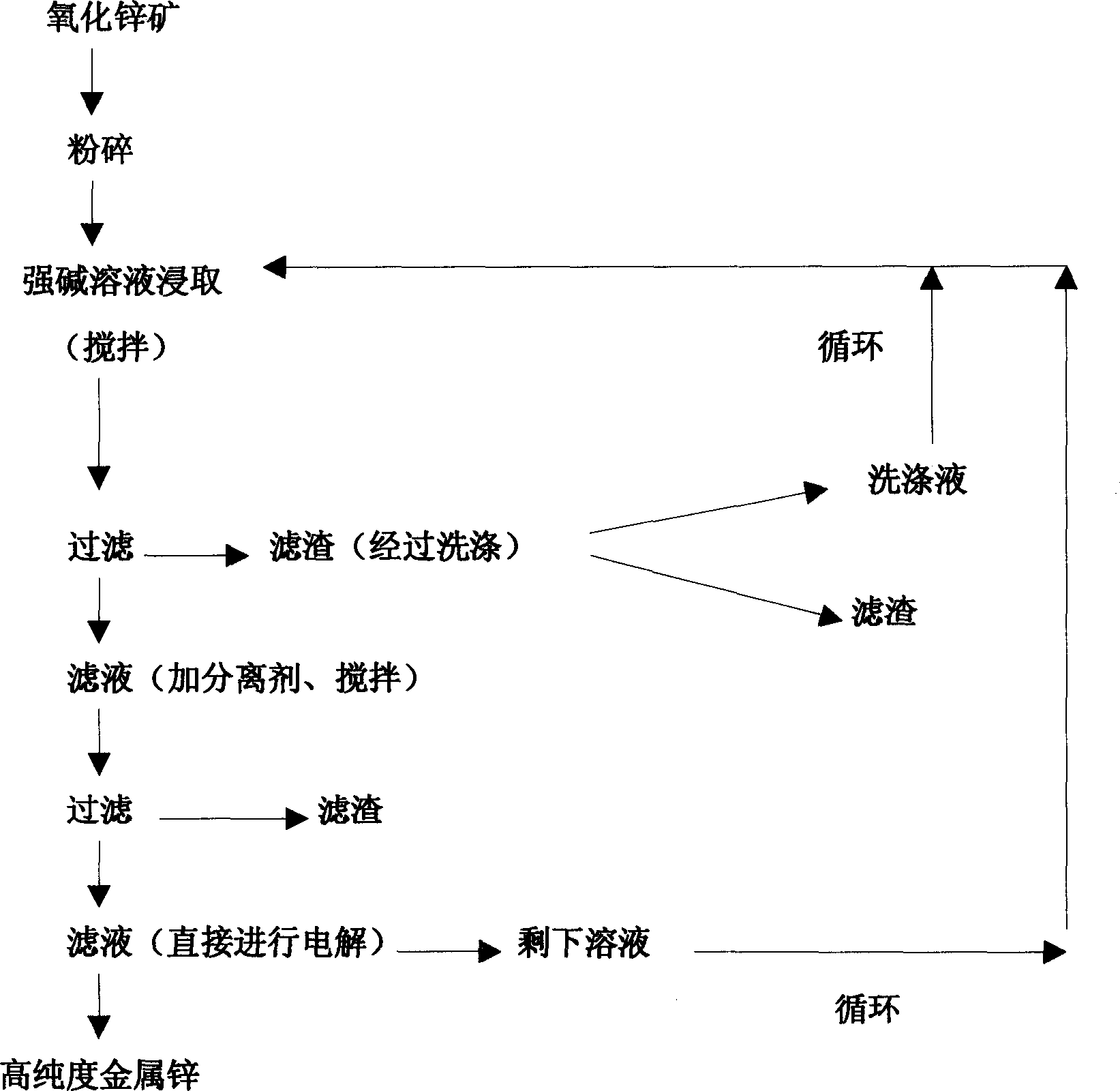

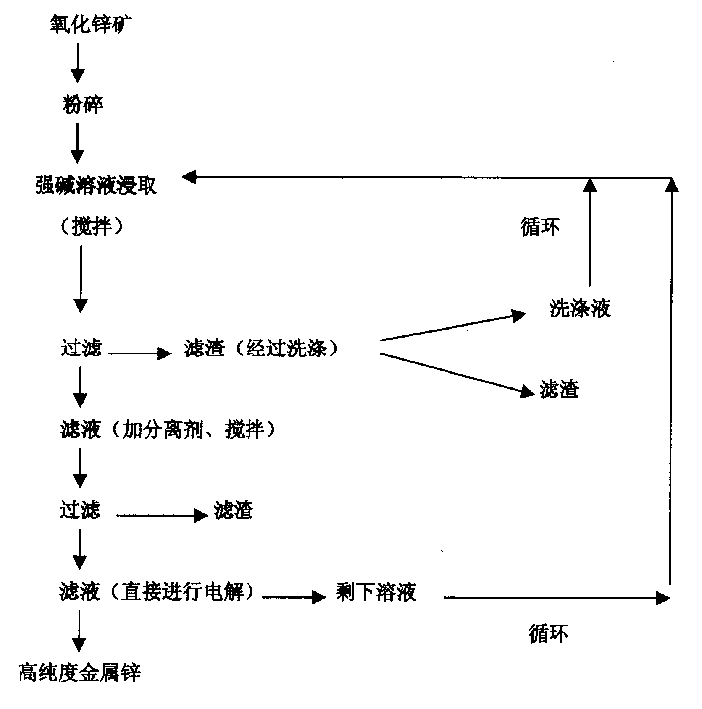

Image

Examples

Embodiment 1

[0014] Please refer to the attached figure 1 . First of all, the zinc oxide ores produced in Kunming, Yunnan, mainly including smithsonite and red zinc ore, are selected. The main components of these two ores are zinc carbonate, zinc silicate and zinc oxide (ZnCO 3 , Zn 2 SiO 4 , 2ZnCO 3 3Zn(OH) 2 , ZnO, Zn 2 SiO 3 h 2 O) and lead, both of which are readily soluble in strong alkaline solutions. Then crush the zinc oxide ore to 0.1-0.8mm. Then, leaching with industrial caustic soda solution: immerse 1 ton of zinc oxide ore into 3-10 cubic meters of industrial caustic soda solution for feeding, the leaching temperature is controlled at 10-95°C, the concentration of industrial caustic soda solution is 5-10M, and the After reacting for 90 minutes under the slow stirring condition of 10 minutes, the extraction rates of zinc and lead in the ore are respectively 98% and 93%. Filter, discharge the filter residue, and add a separating agent to the filtrate. Separating agent ...

Embodiment 2

[0016] First, the zinc oxide ores in Guiyang, including smithsonite and red zinc ore, were selected. The main components of these two ores are zinc carbonate, zinc silicate and zinc oxide (ZnCO 3 , Zn 2 SiO 4 , 2ZnCO 3 3Zn(OH) 2 , ZnO, Zn 2 SiO 3 h 2 O,) and lead and trace copper, iron, they are all easily soluble in strong alkali solution. Then, crush the zinc oxide ore to 0.5-1mm. Then, leaching with calcium hydroxide solution: immerse 1 ton of zinc oxide ore into 3 cubic meters of calcium hydroxide solution and feed, the leaching temperature is controlled at 100 ° C, the concentration of calcium hydroxide solution is 10M, and the slow speed of 120 rpm After reacting for 100 minutes under the condition of high-speed stirring, the extraction rates of zinc and lead in the ore are both 100%. Next, after the zinc and lead in the zinc oxide ore are leached, it is filtered while it is hot, and the filter residue is washed with the above-mentioned concentration of calcium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com