Preparation method of activator

A technology of activator and zinc ore, applied in the direction of zinc halide, etc., can solve the problems of high process cost and unsuitable for mass production, and achieve the effect of wide source and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

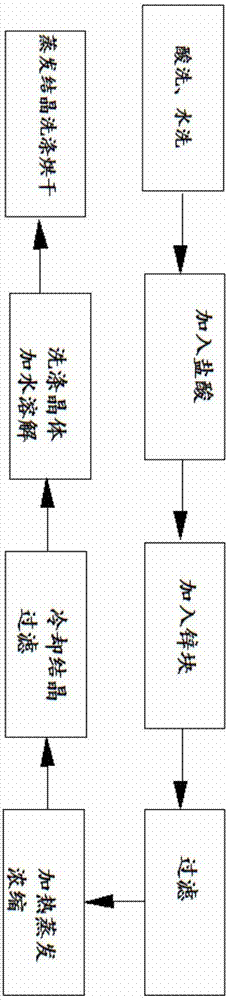

[0015] refer to figure 1 , the preparation method of a kind of activator of the present invention comprises the following steps:

[0016] 1. Clean the zinc ore

[0017] Put one part of zinc ore in a container, wash its surface with 0.1 part of hydrochloric acid, and then wash the zinc ore with distilled water for 2 to 3 times.

[0018] 2. Preparation of zinc chloride solution

[0019] Put the solid obtained in step 1 into a container, add 1.7 parts of 3mol / L propylene hydrochloride and keep stirring.

[0020] The reaction equation is: ZnO+2HCl==ZnCl2+H2O

[0021] 3 Remove impurities

[0022] Add 0.15 parts of zinc nuggets to the resulting solution and stir continuously. When the size of the zinc nuggets no longer changes, stop stirring and filter, discard the filter residue, and use the filtrate for later use.

[0023] 4 Preparation of finished products

[0024] Heat, evaporate and concentrate the filtered filtrate, stop heating when a clear crystal film appears on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com