High-efficiency blende flotation method

A sphalerite and high-efficiency technology, applied in flotation, solid separation, etc., can solve the problems of high single roughing operation load, increased tailings scavenging burden, low enrichment ratio and enrichment efficiency, and achieve strong Adaptability, the effect of increasing the flotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

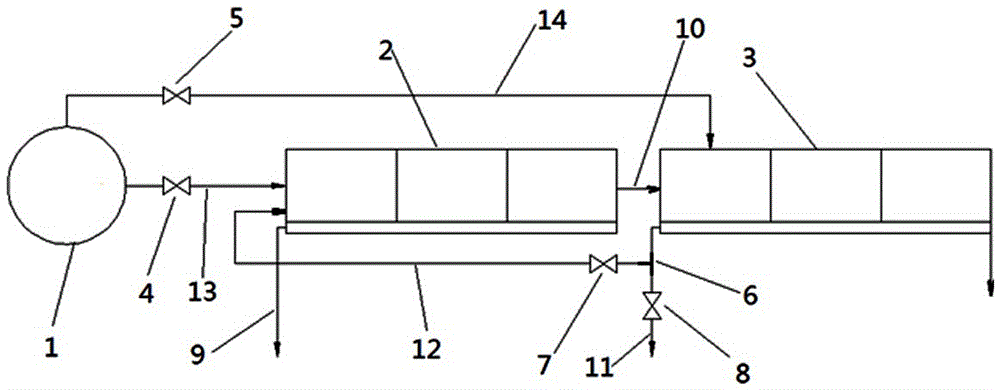

[0013] see figure 1 , the mixing tank 1 for pulp mixing flows out of two pipelines respectively equipped with gate valve I4 and gate valve II5, one pipeline leads to the flotation machine 2 of zinc roughing I, and the other pipeline leads to flotation machine 3 of zinc roughing II; The concentrate outlet of flotation machine 3 of zinc roughing II is equipped with gate valve III7 and gate valve IV8 respectively through tee 6, gate valve III7 is connected to flotation machine 2 of zinc roughing I through pipeline 12, and gate valve IV8 is connected to the final concentrate. The specific process is as follows.

[0014] ①The raw ore for flotation is high-grade extremely rich lead-zinc sulfide raw ore (with more than 6.5% lead, more than 15.5% zinc, industrial grade lead 1.0%, zinc 2.0%) firstly through the lead-sulfur mixed flotation process to separate lead and Sulfur, resulting in a mixture of sphalerite and gangue;

[0015] ② Add activator CuSO to the mixture of sphalerite an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com