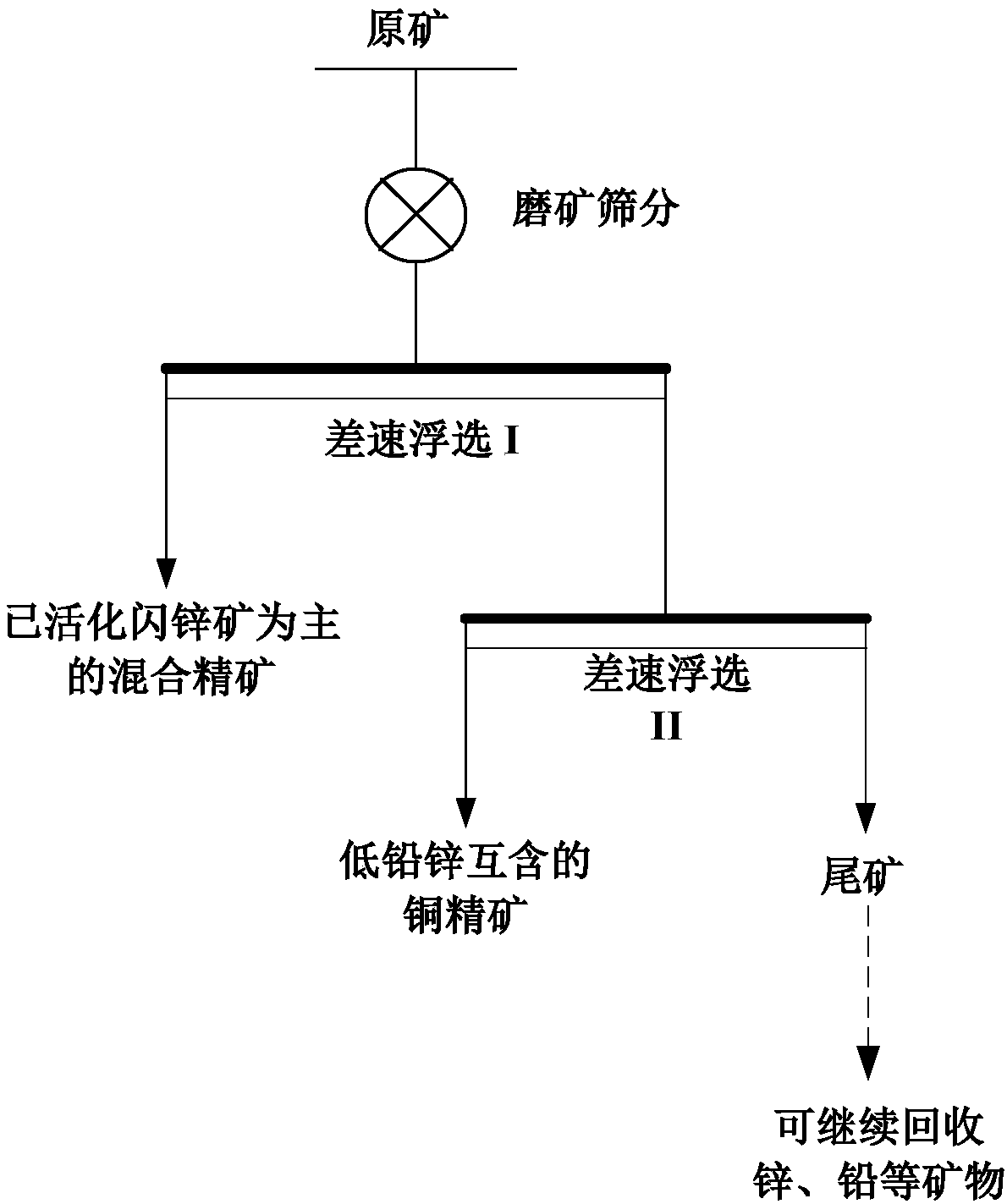

Partial zinc blende activated complex copper-lead-zinc sulfide ore differential flotation separation method

A sphalerite and sulfide ore technology, applied in flotation, solid separation, etc., can solve the problems of low recovery rate of copper, lead and zinc, large dosage of chemicals, high lead-zinc mutual content, etc., to improve the beneficiation index and the total recovery rate , the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A copper sulfide lead-zinc mine in Jiangxi contains 2.62% copper, 4.12% zinc and 0.71% lead. Using the process of the present invention, add 300g / t sodium sulfide, 500g / t sodium sulfite, and 3200g / t zinc sulfate to the raw ore and grind it to -0.074mm to account for 88%, use sodium hydroxide to adjust the pH to 7, add 100g / tZ105, 15g / t No.2 oil, differential flotation for 6 minutes to obtain copper-lead-zinc mixed concentrate. Then add 150g / t sodium sulfide, 250g / t sodium sulfite, 1600g / t zinc sulfate to the tailings, adjust the pH to 10-11 with sodium hydroxide, add 50g / t Z105 and 7g / t No. 2 oil, flotation for 8 minutes to select Produce high-grade copper concentrate. Final beneficiation indicators: the grades of copper, lead and zinc in the mixed concentrate are 5.32%, 3.45%, and 20.16%, respectively. The copper grade in the copper concentrate is 19.09%, and the content of lead and zinc is 5.54% (1.73%Pb+3.81%Zn). The total recoveries of copper, lead and zinc elem...

Embodiment 2

[0044] A flotation test was carried out on a certain copper sulfide lead-zinc ore in Yunnan by the method of the present invention. The raw ore contains 1.88% copper and 3.36% zinc. The process is as follows: add 1000g / t sodium sulfite and 4000g / t zinc sulfate to the raw ore and grind the ore to -0.074mm to account for 80%, use lime to adjust the pH to 8, add 50g / t butyl xanthate, 30g / t No. 2 oil, differential Flotation for 2 minutes to obtain copper-lead-zinc mixed concentrate. Then add 500g / t sodium sulfite and 2000g / t zinc sulfate to the tailings, adjust the pH to 9-10 with sodium hydroxide, add 25g / t butyl xanthate and 15g / t No. 2 oil, and select high-grade by flotation for 10 minutes copper concentrate. Final beneficiation indicators: the grades of copper, lead and zinc in the mixed concentrate are 4.15% and 18.18% respectively. The copper grade in the copper concentrate is 16.67%, and the zinc content is 6.98%. The total recoveries of copper and zinc elements are 84....

Embodiment 3

[0052] The method of the invention is used to carry out the flotation test on the copper sulfide lead-zinc ore. The raw ore contains 3.65% copper, 3.92% zinc, and 1.79% lead. The process is as follows: add 500g / t sodium sulfide and 1800g / t zinc sulfate to the raw ore and grind the ore to -0.074mm to account for 90%, use lime to adjust the pH to 6, add 100g / t ethyl disulfide nitrogen, 20g / t No. 2 oil, differential flotation for 8 minutes to obtain copper-lead-zinc mixed concentrate. Then add 250g / t sodium sulfide, sodium sulfite, 900g / t zinc sulfate to the tailings, adjust the pH to 10-11 with lime, add 50g / t ethyl disulfide and 10g / t No. grade copper concentrate. Final beneficiation indicators: the grades of copper, lead and zinc in the mixed concentrate are 7.65%, 12.37%, and 19.24%, respectively. The copper grade in the copper concentrate is 22.09%, and the content of lead and zinc is 5.96% (2.33%+3.63%). The total recoveries of copper, lead and zinc elements are 76.65%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com