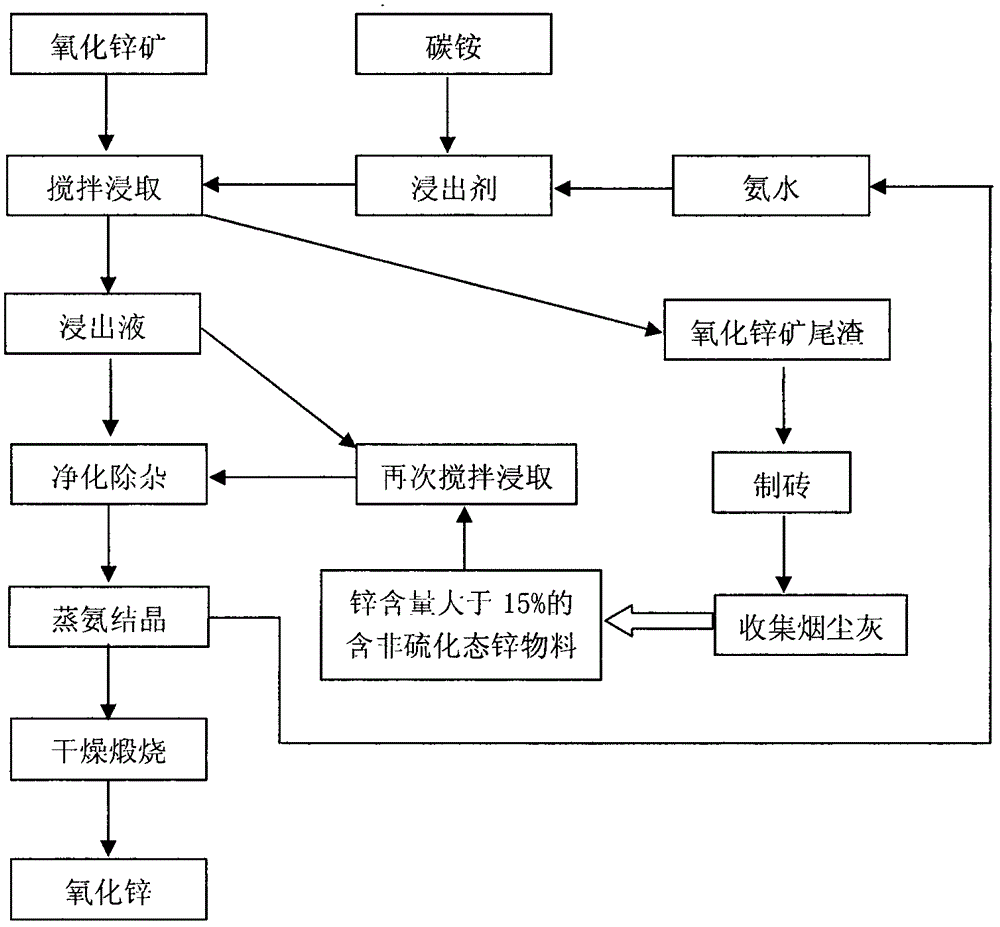

Comprehensive utilization method for zinc oxide ore

A zinc oxide ore and zinc oxide technology, which is applied in the direction of zinc oxide/zinc hydroxide, zinc sulfide, nanotechnology for materials and surface science, etc., can solve the problem of high mud content, low zinc concentration in leachate, and impurity components Complicated issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Raw material: a zinc oxide mine in Yunnan 1 # , its composition is: Zn15.68%.Fe18.20%.SiO 2 7.94%, and its zinc phase composition is 9.49% zinc carbonate, 2.12% zinc silicate, 0.83% zinc sulfide, and 3.14% iron-zinc spinel.

[0059] Method for preparing zinc oxide:

[0060] (1) Leaching: 500g of low-grade zinc oxide ore 1 # Carry out leaching with 1500ml ammoniacal liquor-ammonium bicarbonate liquid as leaching agent; Wherein, the molar concentration c(NH 3 ·H 2 O)=4.5mol mol / L, CO 3 2 and HCO 3 The molar concentration of c(CO 3 2 +HCO 3 )=1.2mol / L, add sodium dodecylbenzene sulfonate in the amount of 0.3kg sodium dodecylbenzene sulfonate added in the leaching agent per cubic meter of leaching agent; when leaching, adopt ball milling, and ensure The leaching time in the ball mill is 60 minutes, and all the materials at the outlet of the ball mill pass through an 80-mesh sieve; the total leaching time is 3 hours, and the temperature is 40°C; after solid-liquid ...

Embodiment 2

[0065] Raw material: zinc oxide ore 2 # , its composition is: Zn9.67%.Fe18.34%.SiO 2 17.62%, CaO9.34%, its zinc phase composition is zinc carbonate 12.28%, zinc silicate 2.37%, zinc sulfide 0.82%, iron-zinc spinel 3.20%.

[0066] Method for preparing zinc oxide:

[0067] (1) Leaching: 5000g zinc oxide ore 2 # Carry out leaching with 15000ml ammoniacal liquor-ammonium bicarbonate liquid as leaching agent; Wherein, the molar concentration c(NH 3 ·H 2 O)=7mol mol / L, CO 3 2- and HCO 3 - The molar concentration of c(CO 3 2- +HCO 3 -)=1.5mol / L, add sodium dodecylbenzenesulfonate in the amount of adding 0.05kg of surfactant sodium dodecylbenzenesulfonate in every cubic meter of leaching agent; when leaching, adopt ball milling, and Ensure that the leaching time in the ball mill is 60 minutes, and all the materials at the outlet of the ball mill pass through a 120-mesh sieve; the total leaching time is 3 hours, and the temperature is 25°C; the zinc in the obtained zinc-amm...

Embodiment 3

[0073] Raw material: zinc oxide ore 3 # , its composition is: Zn13.6%.Fe18.67%.SiO 2 17.83%, Al 2 o 3 9.92%, CaO9.34%, its zinc phase composition is zinc carbonate 7.96%, zinc silicate 2.21%, zinc sulfide 0.76%, iron-zinc spinel 2.67%.

[0074] Method for preparing zinc oxide:

[0075] (1) Leaching: 1t zinc oxide ore 3 # Carry out leaching with 3000L ammoniacal liquor-ammonium bicarbonate liquid as leaching agent; Wherein, the molar concentration c(NH 3 ·H 2 O)=5.8mol mol / L, CO 3 2- and HCO 3 - The molar concentration of c(CO 3 2 +HCO 3 )=1.15mol / L, add the amount SDS of the surfactant SDS of 00.01kg in every cubic meter of leaching agent; Mesh sieve; the total leaching time is 3.5 hours, and the temperature is 35°C; after solid-liquid separation, 119.95 kilograms of zinc in the obtained zinc-ammonia complex solution; the leaching rate of zinc oxide ore zinc is 88.19%; add 55% secondary zinc oxide Leach again, and the obtained leaching solution contains zinc Zn=7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com