Beneficiation method for complex multi-metal sulfide electrum comprehensive recovery

A beneficiation method and multi-metal technology, applied in the field of smelting, can solve the problems of fine embedded particle size, difficult processing, complex embedded relationship between sphalerite and pyrite, etc., and achieve efficient recovery and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

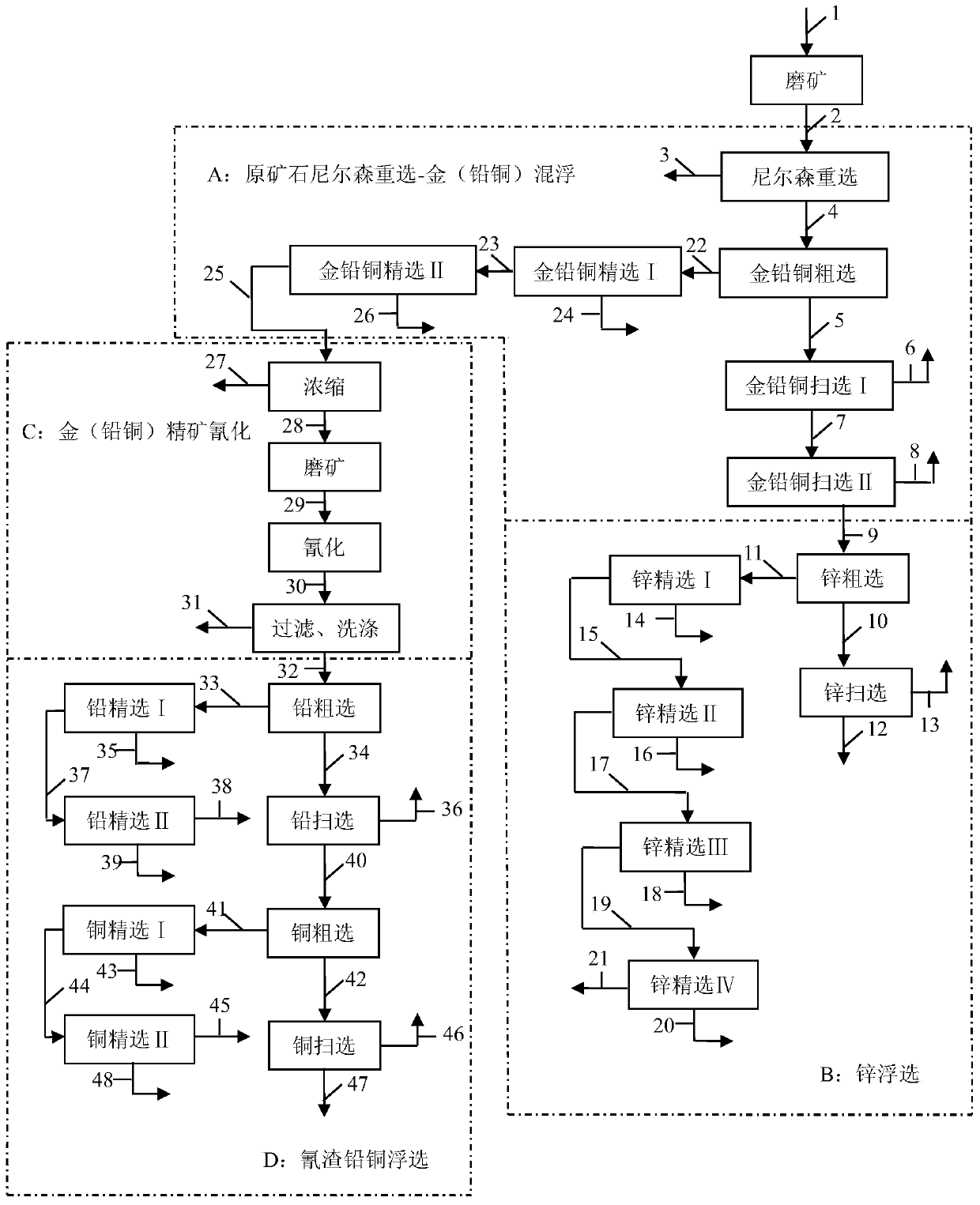

[0013] Example 1: First, the crushed raw ore and water are added to a ball mill at a ratio of 1:1 for grinding until the grinding fineness of the discharged material reaches -0.074mm, accounting for 72%. Carry out Nelson gravity separation with ball mill discharge, add 450g / t of sodium sulfite (based on the weight of raw ore dry ore, the same below) and 900g / t of zinc sulfate to the tailings of Nelson gravity separation, and then add 450g / t of water glass, After pulping with 90g / t of BK301 and 25g / t of pine alcohol oil, roughing of gold, lead and copper was carried out; addition of 75g / t of water glass was used for the first selection of gold, lead and copper, and the second selection of gold, lead and copper was used Blank selection; add BK301 dosage 25g / t, terpineol oil dosage 15g / t for the first gold-lead-copper sweep, add BK301 dosage 15g / t for the second gold-lead-copper sweep, gold-lead-copper each time Concentration and gold-lead-copper screening are returned to the pre...

Embodiment 2

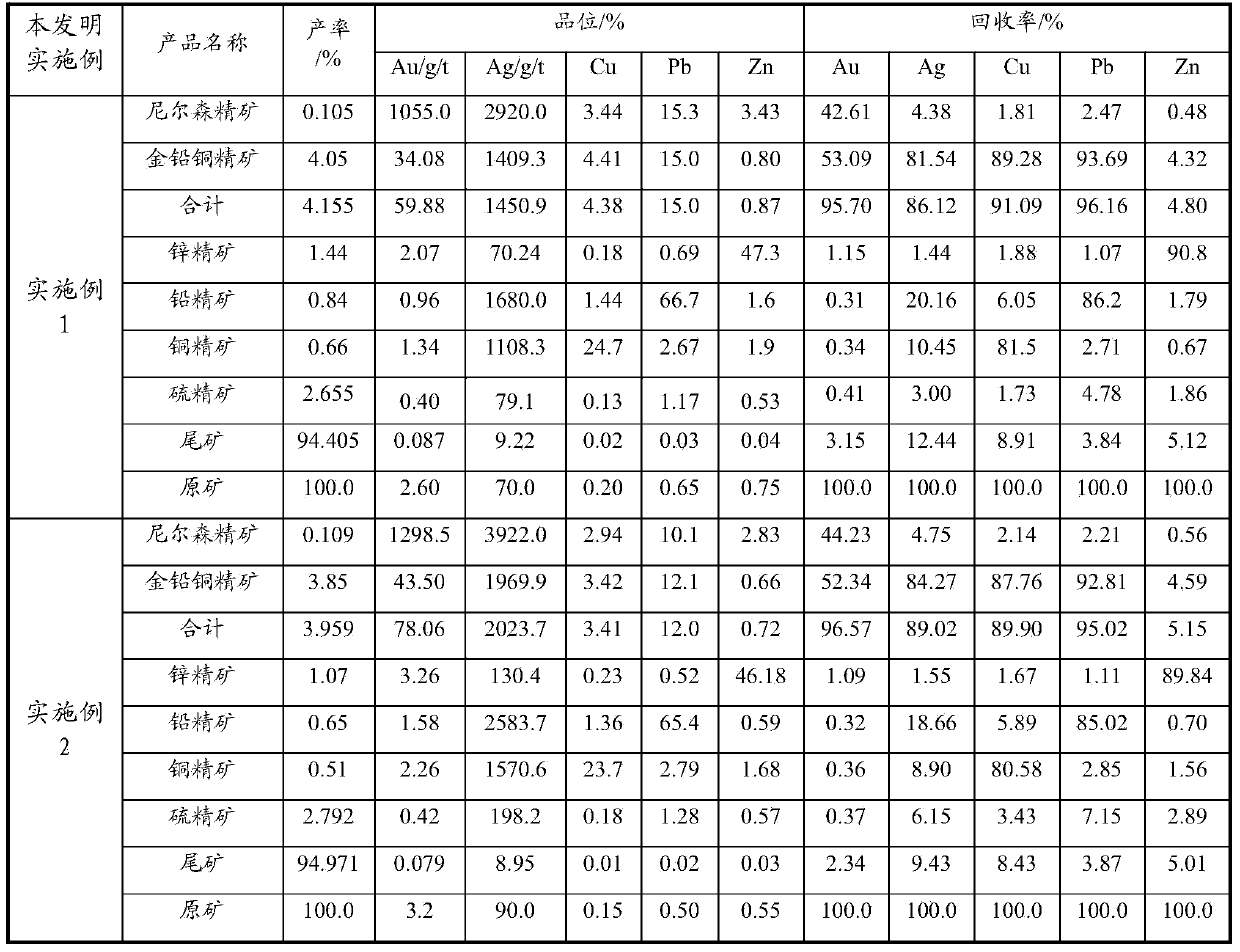

[0014] Embodiment 2: According to figure 1 The embodiment of the technological process of the present invention, the test steps, process parameters, and medicament system are exactly the same as those in Example 1. The technological indexes of embodiment 1 and embodiment 2 of the present invention are shown in table 1. Shown by the implementation situation shown in table 1, adopt the inventive method, the raw ore of embodiment 1 contains gold 2.6g / t, silver 70.0g / t, zinc 0.75%, copper 0.20%, lead 0.65%, comprehensive beneficiation index is: Nielsen Gravity separation concentrate contains 1055.0g / t gold, recovery rate 42.61%, silver content 2920.0g / t, recovery rate 4.38%; gold-lead-copper flotation concentrate contains gold 34.08g / t, recovery rate 53.09%, silver content 1409.3% g / t, the recovery rate is 81.54%; the total recovery rate of gravity + flotation gold is 95.70%, and the total recovery rate of silver is 86.12%. The zinc concentrate grade is 47.3%, and the zinc recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com