Method for reinforcing leaching of chalcopyrite microorganisms

A technology for microbial leaching and leaching microorganisms, which is applied in the direction of improving process efficiency, can solve the problems of low leaching rate and poor oxidative decomposition effect of chalcopyrite, and achieves strong pertinence, long leaching time, and improved oxidative decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

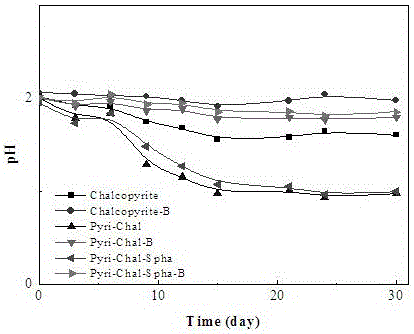

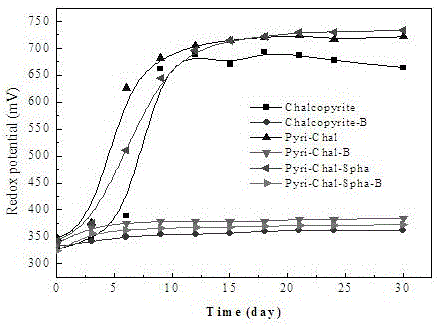

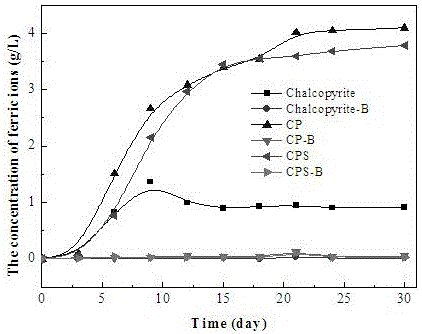

[0030] Thiobacillus thermophilus Acidithiobacillus caldus , Thermosulfobacillus thiooxidans Sulfobacillus Thermosulfidooxidans , Leptospira siderophilum Leptospirillum ferriphilum and thermophilic ferrobacteria Ferroplasma thermophilum (These four types of strains are all stored in the Wuhan University Preservation Center, located in Wuhan University, No. 299, Bayi Road, Wuchang District, Wuhan City, Hubei Province) The artificial co-cultivation system formed by leaching the chalcopyrite system with pyrite added: the chalcopyrite and pyrite ore were pulverized into particles of about 0.074mm, and put into 9K medium containing microbial enrichment, the leaching condition was 2% pulp concentration, and the microbial concentration of the leaching solution after inoculation was 1.0×10 6 pc / ml, pH value is 2.0, culture temperature is 40 DEG C, shaker rotating speed 170rpm, leaching 30 days, wherein chalcopyrite and pyrite add in equal proportion. When chalcopyrite is ...

Embodiment 2

[0032] Thiobacillus thermophilus Acidithiobacillus caldus , Thermosulfobacillus thiooxidans Sulfobacillus Thermosulfidooxidans , Leptospira siderophilum Leptospirillum ferriphilum and thermophilic ferrobacteria Ferroplasma thermophilum The formed artificial co-cultivation system is used to leach the chalcopyrite system added with pyrite and sphalerite: pulverize the chalcopyrite, pyrite and sphalerite ore into particles of about 0.074mm, and put them into the artificial co-cultivation system In the 9K medium, the leaching condition is that the pulp concentration is 2%, and the microbial concentration of the leaching solution after inoculation is 1.0×10 6 pc / ml, pH value is 2.0, culture temperature is 40 ℃, shaker rotating speed 170rpm, leaching 30 days, wherein chalcopyrite, pyrite and sphalerite are to add in equal proportion. When chalcopyrite is in the microbial leaching system alone, after 9 days of leaching, the pH value is 1.75 ( figure 1 ), Eh is 662 ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com