Non-copper sulphide ore inhibitor and application thereof

An inhibitor, sulfide ore technology, applied in solid separation, flotation and other directions, can solve the problems of difficult large-scale use, harsh preparation conditions, high cost, and achieve the effects of low price, strong selectivity and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of non-copper sulfide mineral inhibitor, prepared by the following steps:

[0031] In parts by mass, 2 parts of xanthan gum, 1.5 parts of pectin, and 1.5 parts of gum arabic were mixed and evenly stirred to obtain a non-copper sulfide mineral inhibitor.

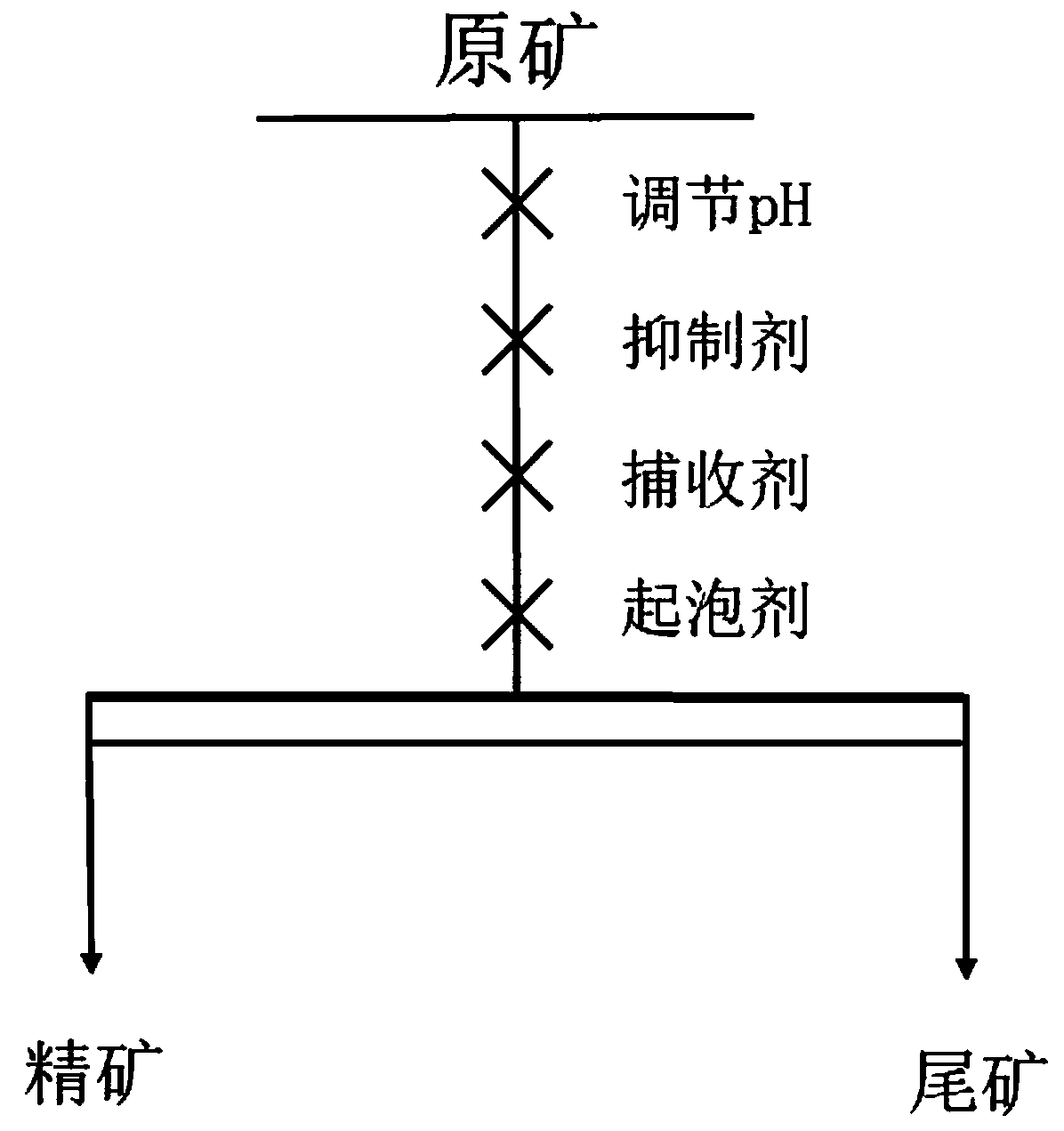

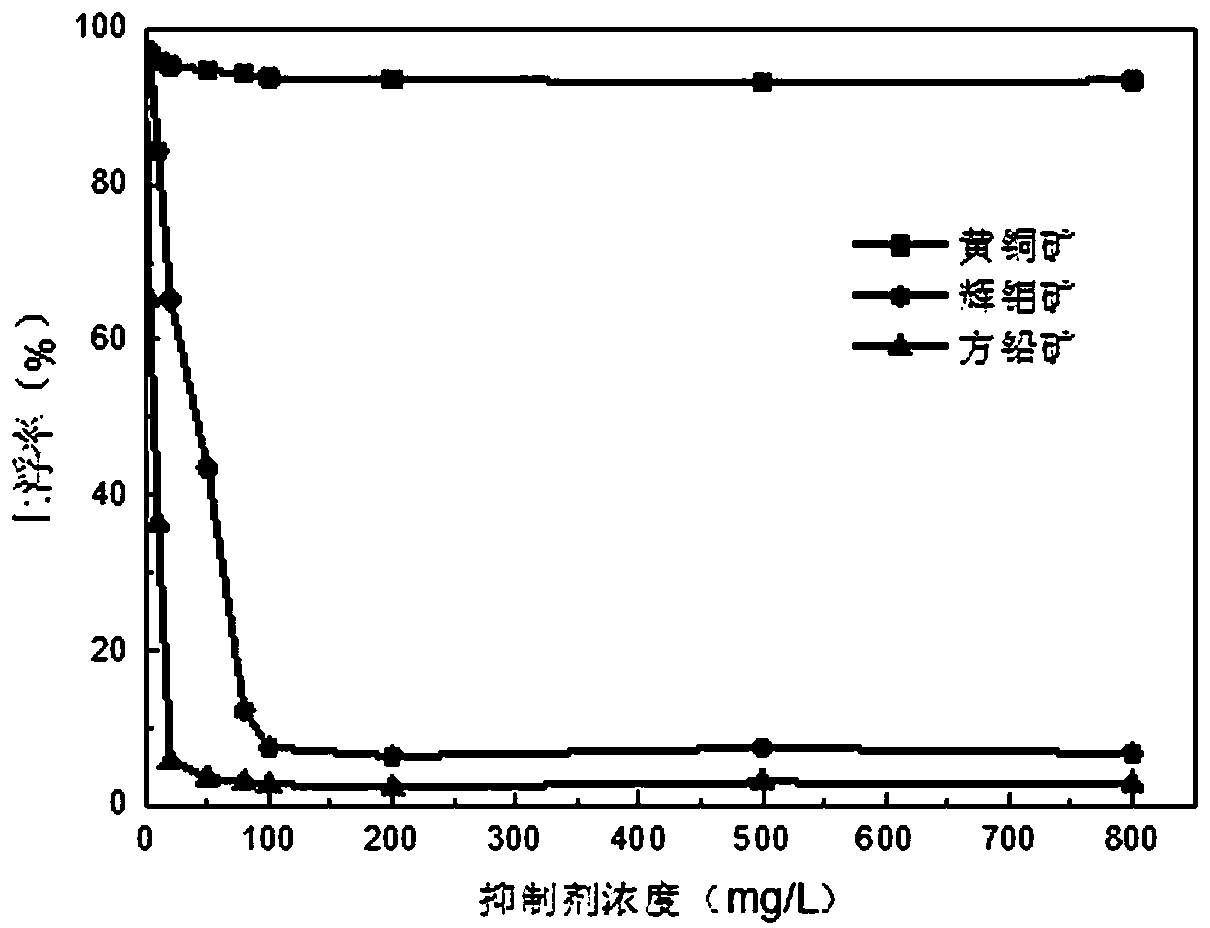

[0032] The prepared non-copper sulfide inhibitors were applied to chalcopyrite, molybdenite, and galena single mineral flotation with a particle size of +38-74 μm, such as figure 1 shown, including the following steps:

[0033] (1) Take 2g of chalcopyrite, molybdenite, and galena respectively, add them to 50mL of distilled water, then place them in a 70mL hanging tank flotation machine, stir and adjust the pulp at a speed of 1300r / min to fully disperse the pulp , and adjust the pulp pH to 9.

[0034] (2) Add the inhibitors prepared above to the pulp respectively, and stir for 5 minutes; then add 30mg / L xanthate as a collector, and stir for 2 minutes; finally add 20mg / L MIBC as a foaming agent, and stir for 1 m...

Embodiment 2

[0038] A kind of non-copper sulfide mineral inhibitor, prepared by the following steps:

[0039] In parts by mass, 1 part of xanthan gum, 1 part of pectin and 1 part of gum arabic are mixed and evenly stirred to obtain the non-copper sulfide mineral inhibitor.

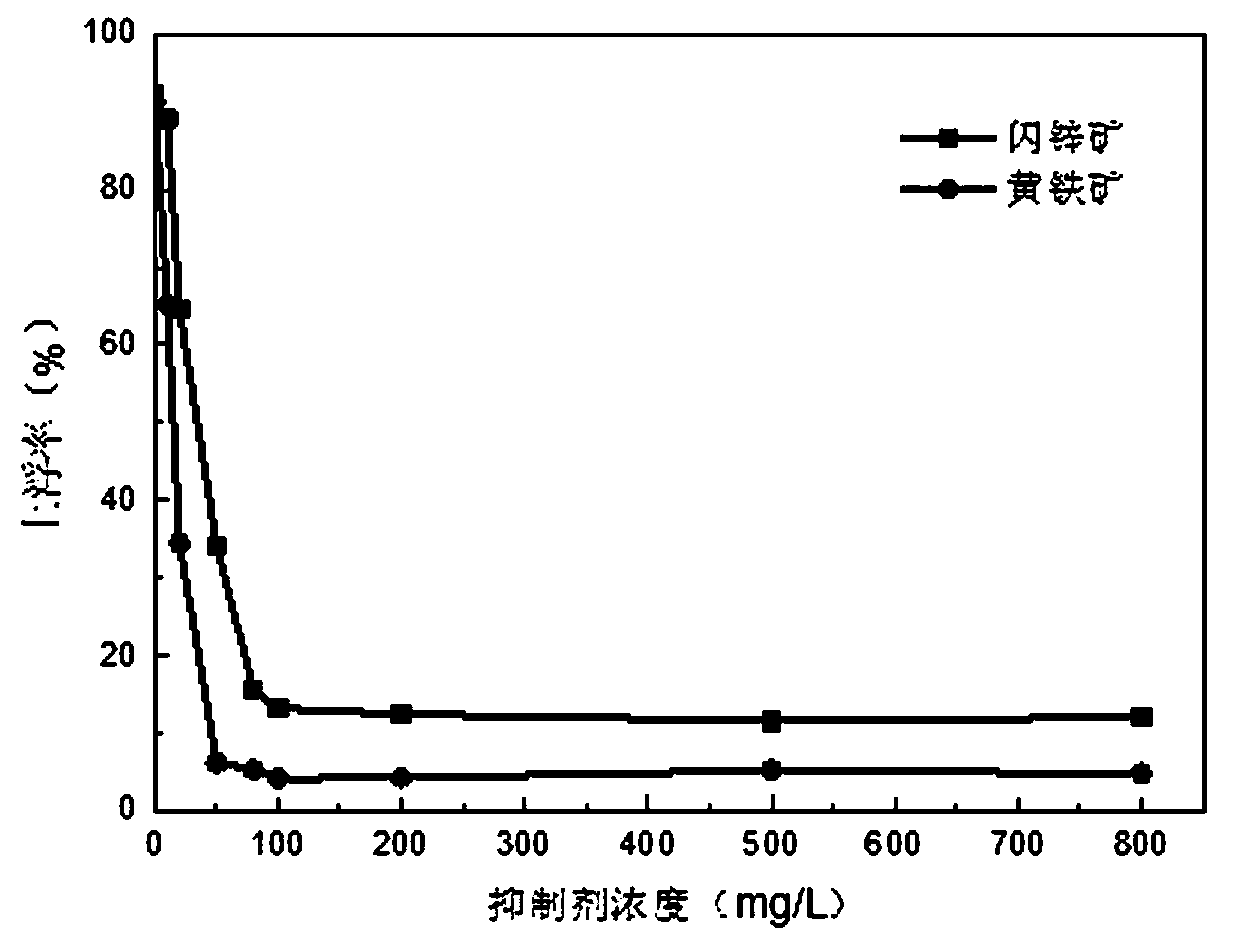

[0040] The prepared non-copper sulfide inhibitors are applied to single mineral flotation of sphalerite and pyrite with a particle size of +38-74 μm, including the following steps:

[0041] (1) Take 2g of sphalerite and pyrite respectively, add them to 50mL of distilled water, then place them in a 70mL hanging tank flotation machine, stir and adjust the slurry at a speed of 1300r / min to fully disperse the slurry, and adjust the slurry pH is 8.

[0042] (2) Add the inhibitors prepared above to the pulp respectively, and stir for 5 minutes; then add 30mg / L butyl xanthate as a collector, and stir for 2 minutes; finally add 20mg / L MIBC as a foaming agent, and stir for 1 minute. The concentrations of the inhibitors added ...

Embodiment 3

[0046] A kind of non-copper sulfide mineral inhibitor, prepared by the following steps:

[0047] According to parts by mass, 3 parts of xanthan gum, 2 parts of pectin and 2 parts of gum arabic are mixed and evenly stirred to obtain the non-copper sulfide mineral inhibitor.

[0048] The prepared non-copper sulfide inhibitors were applied to +38-74 μm chalcopyrite, molybdenite, and galena single mineral flotation, including the following steps:

[0049] (1) Take 2g of chalcopyrite, molybdenite, and galena respectively, add them to 50mL of distilled water, then place them in a 70mL hanging tank flotation machine, stir and adjust the pulp at a speed of 1300r / min to fully disperse the pulp , adjust the pH of the pulp to 6, 8, 9, 10, 12.

[0050] (2) Add the above-prepared inhibitors to the pulp respectively, and stir for 5 minutes; then add 30mg / L black powder as a collector, and stir for 2 minutes; finally add 20mg / L MIBC as a foaming agent, and stir for 1 minute. Among them, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com