Cyanidation aurum-extracting method for preprocessing high-arsenic complex refractory gold ore by oxidation with arsenic resistant strains

A refractory gold ore pretreatment technology, applied in the direction of improving process efficiency, can solve the problems that hinder the application of complex and refractory gold ore with high arsenic, complex components, large changes, etc., achieve good activity and oxidation ability, and promote oxidation , The effect of high gold leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

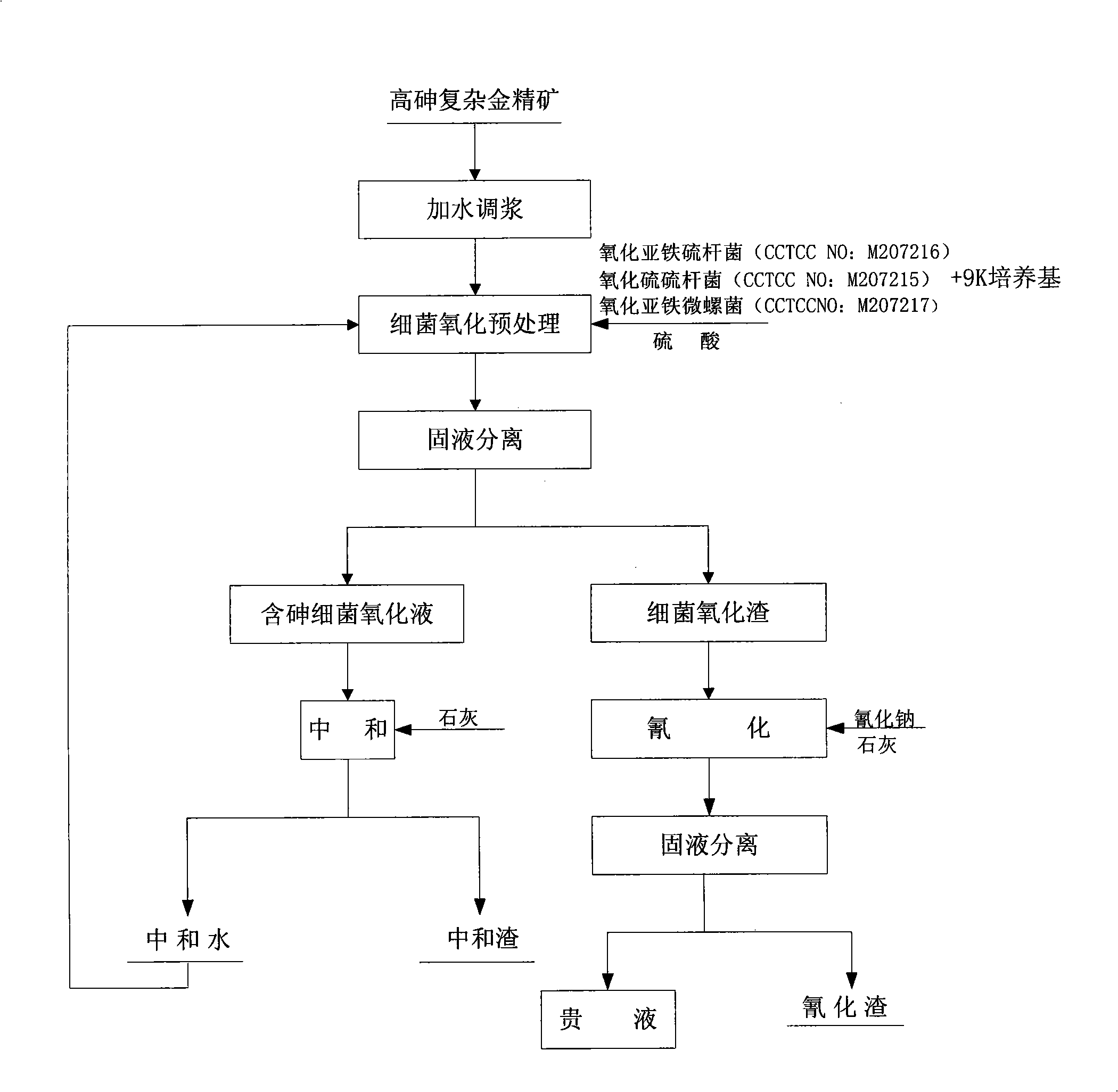

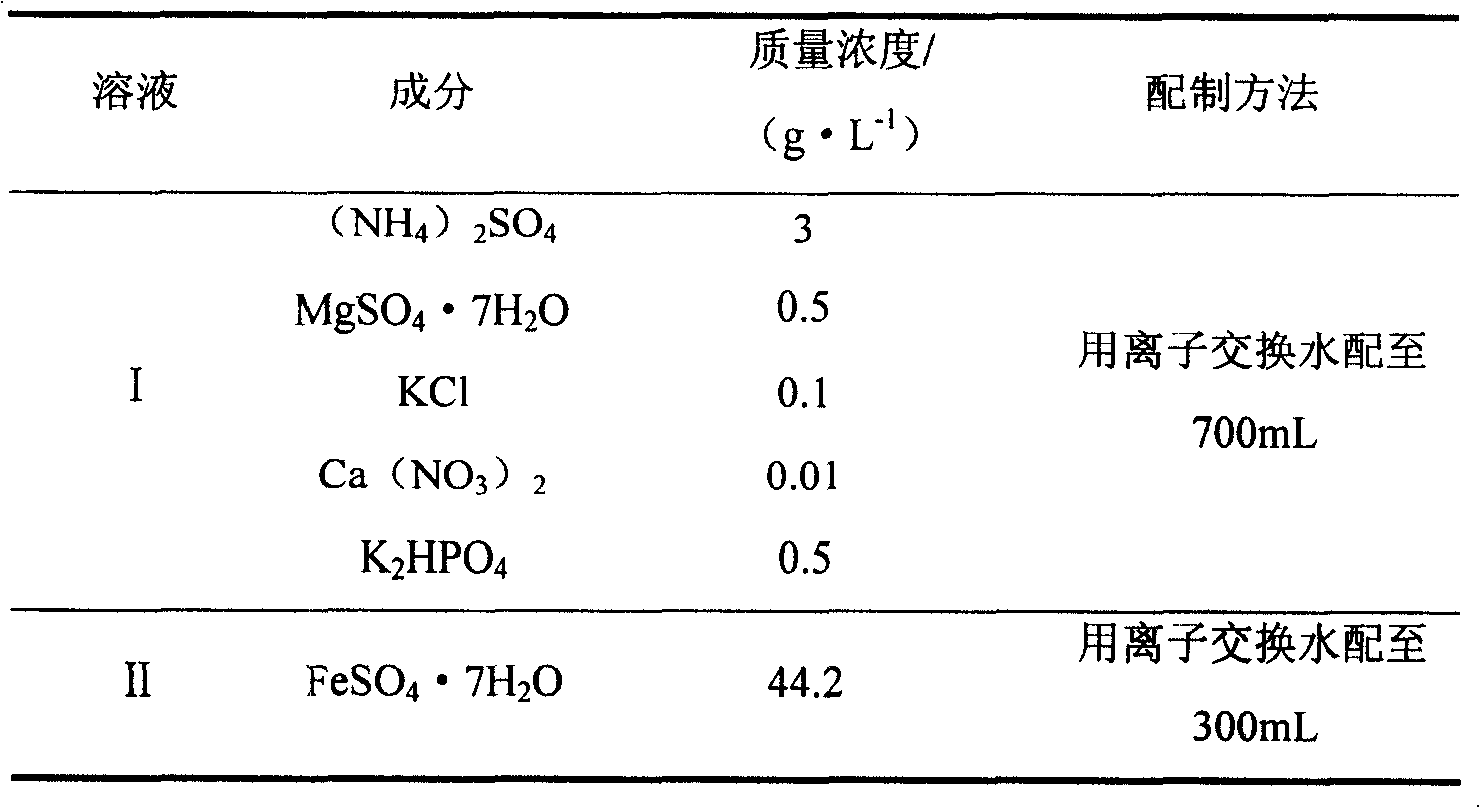

Method used

Image

Examples

example 1

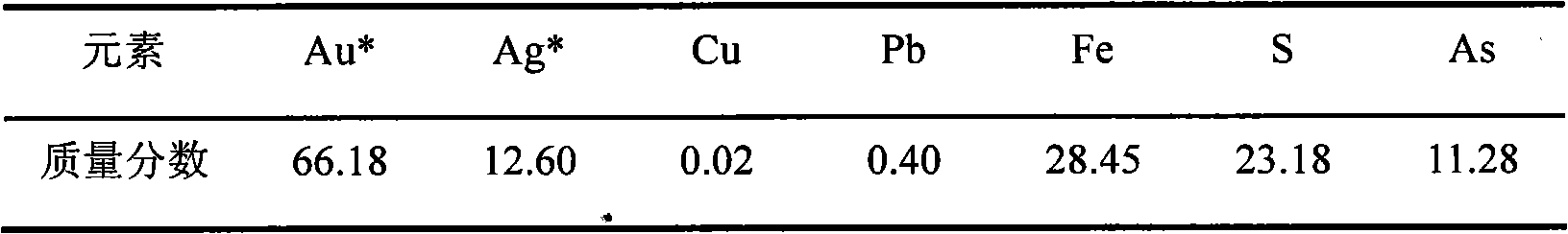

[0036] The composition of the flotation concentrate processed in this example is shown in Table 2:

[0037] Table 2 embodiment 1 concentrate chemical composition analysis (%)

[0038]

[0039] * Unit: (g / t)

[0040] This ore is a high-arsenic complex and refractory concentrate. The gold in the mineral is mainly wrapped by sulfides such as arsenopyrite and pyrite. The direct cyanide leaching rate of gold is only 21.91%.

[0041] 1. Slurry adjustment of flotation concentrate: the flotation gold concentrate with high arsenic complex and refractory is adjusted according to the pulp concentration of 20-30%.

[0042] 2. Bacterial oxidation flotation concentrate: Add the adjusted pulp into the bacterial oxidation tank, the concentration of the pulp in the oxidation tank is 15%, aerate and stir (aeration volume 0.3 ~ 0.5m 3 / h, the stirring speed is 600-1400rpm), the temperature is kept at 44-60°C, the pH value is kept between 1.0-2.0, and the oxidation time is 192 hours. The o...

Embodiment 1

[0046] Table 3 Example 1 Bacterial Oxidation Pretreatment-Cyanide Gold Extraction Results

[0047]

[0048] After the treatment of the invention, the leaching rate of gold is increased by 68.59% compared with direct cyanide leaching.

example 2

[0050] The composition of the flotation concentrate processed in this example is shown in Table 4:

[0051] Table 4 embodiment 2 concentrate chemical composition analysis (%)

[0052]

[0053] * Unit: (g / t)

[0054] This ore is a high-arsenic complex and refractory concentrate. The gold in the mineral is mainly wrapped by sulfides such as arsenopyrite and pyrite. The direct cyanide leaching rate of gold is only 27.2%.

[0055] 1. Slurry adjustment of flotation concentrate: the flotation gold concentrate with high arsenic complex and refractory is adjusted according to the pulp concentration of 20-30%.

[0056] 2. Bacterial oxidation flotation concentrate: Add the adjusted pulp into the bacterial oxidation tank, the concentration of the pulp in the oxidation tank is 15%, aerate and stir (aeration volume 0.3 ~ 0.5m 3 / h, the stirring speed is 600~1400rpm), the temperature is kept at 44~60°C, the pH value is kept between 1.0~2.0, and the oxidation time is 96 hours. The oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com