Method for recovering gold and silver from refractory gold ores

A technology for refractory gold mines and recovery of gold, which is applied in the field of metallurgy, can solve the problems of large environmental pollution, high equipment cost and maintenance costs, and bacterial death, and achieve obvious economic and social benefits, reduce environmental pollution, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

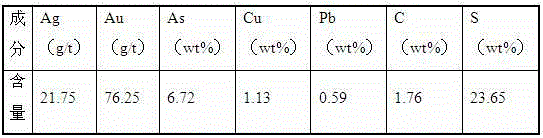

[0024] Treat 2t of gold concentrate from a mine in Gansu, its chemical composition is shown in the following table:

[0025]

[0026] If the gold concentrate is treated with direct cyanidation, the gold leaching rate is 32%, and after roasting, the gold cyanide leaching rate is 82%; the sales price is low, and the economic benefit is relatively poor.

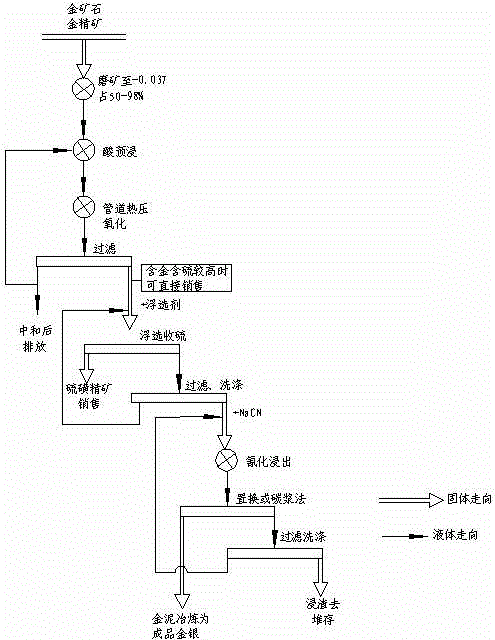

[0027] Above-mentioned gold concentrate utilizes the inventive method to process, as figure 1 As shown, the specific processing steps are as follows:

[0028] Step 1, acid pre-soaking: first finely grind the raw material to -0.037mm, accounting for 85% (mass ratio), add water to make a slurry with a solid-liquid mass ratio of 1:1.5, add 1g / L sulfuric acid, and adjust the pH value to 0.3, Stir for 2 hours;

[0029] Step 2, hot-pressed oxidation: Dilute the pulp from step 1 with water to a solid-liquid mass ratio of 1:3, add 5g / t of lignin ore, pump it into the pipeline stripper through a high-pressure pump, and the flow rate...

example 2

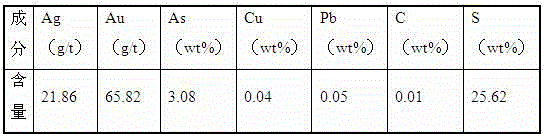

[0033] Process 50kg of gold concentrate from a mine in Kyrgyzstan, its chemical composition is shown in the following table:

[0034]

[0035] If the gold concentrate is directly cyanided, the gold leaching rate is 27%, and after roasting, the gold cyanide leaching rate is 78%; the gold valuation coefficient of the sales price is 70%, and the economic benefit is relatively poor.

[0036] Above-mentioned gold concentrate utilizes the inventive method to process, and concrete processing steps are as follows:

[0037] Step 1, acid pre-soaking: first finely grind the raw material to -0.037mm, accounting for 95% (mass ratio), add water to make a slurry with a solid-liquid mass ratio of 1:1.5, add 500g / L sulfuric acid, adjust the pH to 2, and stir After 5 hours, go to step 2;

[0038] Step 2, hot-pressed oxidation: the pulp from step 1 is diluted with water to a solid-to-liquid mass ratio of 1:3, and 6g / t of lignosulfonate ore is added, and pumped into the pipeline stripper...

example 3

[0041] Processing 100kg of gold concentrate from a mine in Sichuan, its chemical composition is shown in the table below:

[0042]

[0043] If the gold concentrate is directly cyanided, the gold leaching rate is 21%, and the gold cyanide leaching rate after roasting in the smelter is 72%.

[0044] Above-mentioned gold concentrate utilizes the inventive method to process, as figure 1 As shown, the specific processing steps are as follows:

[0045] Step 1, acid pre-soaking: first finely grind the raw material to -0.037mm, accounting for 92% (mass ratio), add water to make a slurry with a solid-liquid mass ratio of 1:1.5, add 300g / L sulfuric acid, and adjust the pH value to 1, After stirring for 0.5 hours, enter step 2;

[0046]Step 2, hot-pressed oxidation: The pulp from step 1 is diluted with water to a solid-to-liquid mass ratio of 1:3, and 10 g / t of lignosulfonate ore is added, and pumped into the pipeline stripper by a high-pressure pump. The flow rate of the pulp pipel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com