Method for recycling gold from refractory gold concentrate

A technology for refractory gold treatment and gold recovery, applied in the direction of improving process efficiency, etc., can solve the problem of low gold recovery rate, achieve the effect of low gold grade, high leaching rate, and less treatment and recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

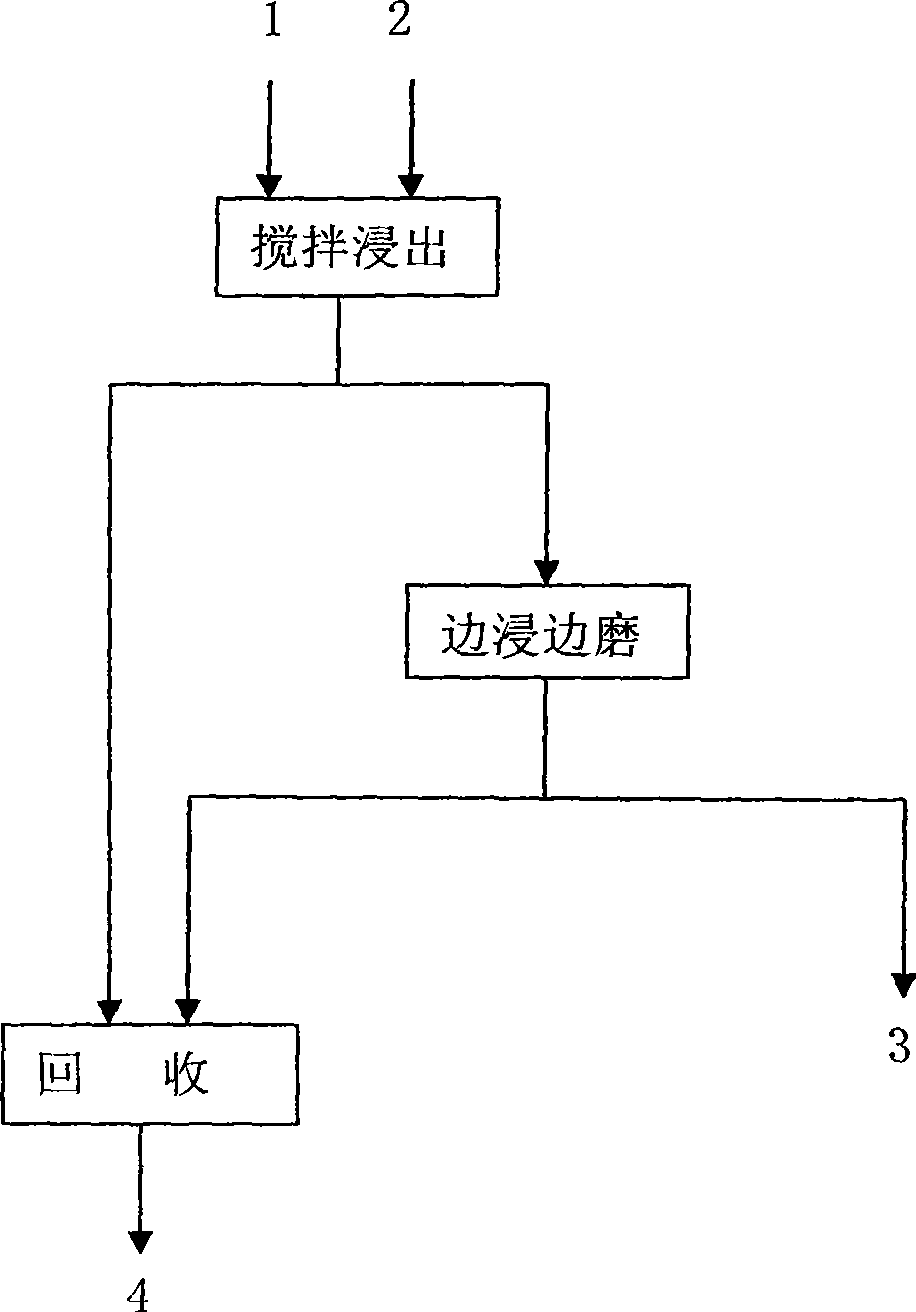

Image

Examples

Embodiment 1

[0028] Use refractory gold concentrate with a particle size of -0.075mm>75% (the grade of gold in the gold concentrate is 186.3g / t), the liquid-solid ratio is 3:1, and the concentration of sodium cyanide is controlled at 3‰, stirring and leaching for 16 hours , and then filter; add the leaching residue that was stirred and leached into the mill and leaching machine, the liquid-solid ratio is 2:1, the concentration of sodium cyanide is controlled at 3‰, soak for 3 hours while grinding, and then filter. The leaching rate of gold reached 98.28%, the grade of gold in the leaching residue was reduced to 3.2g / t, and the consumption of sodium cyanide reached 23.5kg / t. The precious liquid is obtained, and zinc is used for replacement and recovery to obtain sponge gold.

Embodiment 2

[0030] Use refractory gold concentrate with a particle size of -0.075mm>75% (the grade of gold in the gold concentrate is 186.3g / t), the liquid-solid ratio is 4:1, and the concentration of sodium cyanide is controlled at 1‰, stirring and leaching for 24 hours , and then filtered; the conventional cyanide slag was added to the grinding and leaching machine, the liquid-solid ratio was 1:1, the sodium cyanide concentration was controlled at 4‰, soaking for 2 hours while grinding, and then filtering. The leaching rate of gold reached 97.80%, the grade of gold in the leaching residue was reduced to 4.1g / t, and the consumption of sodium cyanide reached 22kg / t. The precious liquid is obtained, and zinc is used for replacement and recovery to obtain sponge gold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com