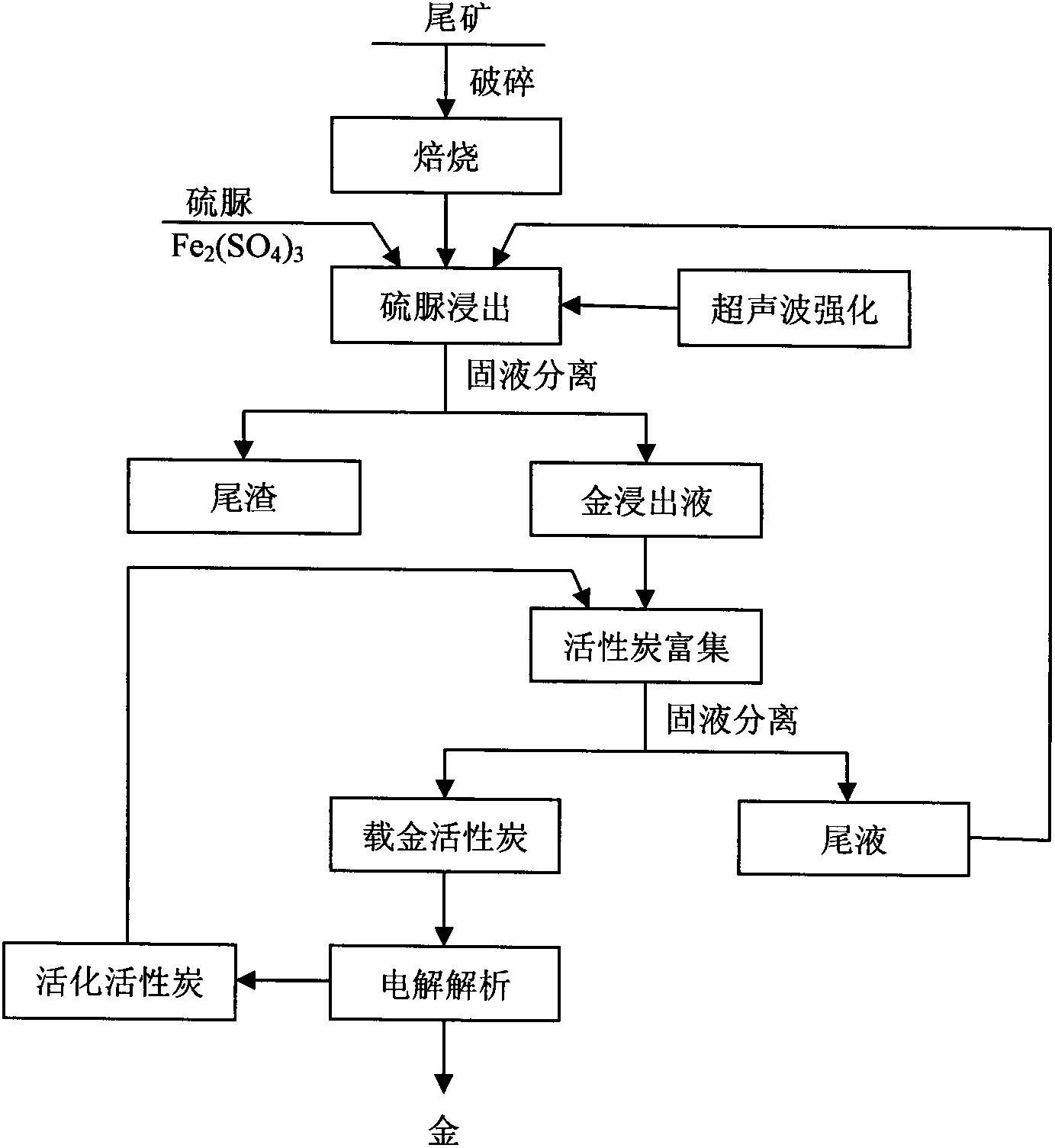

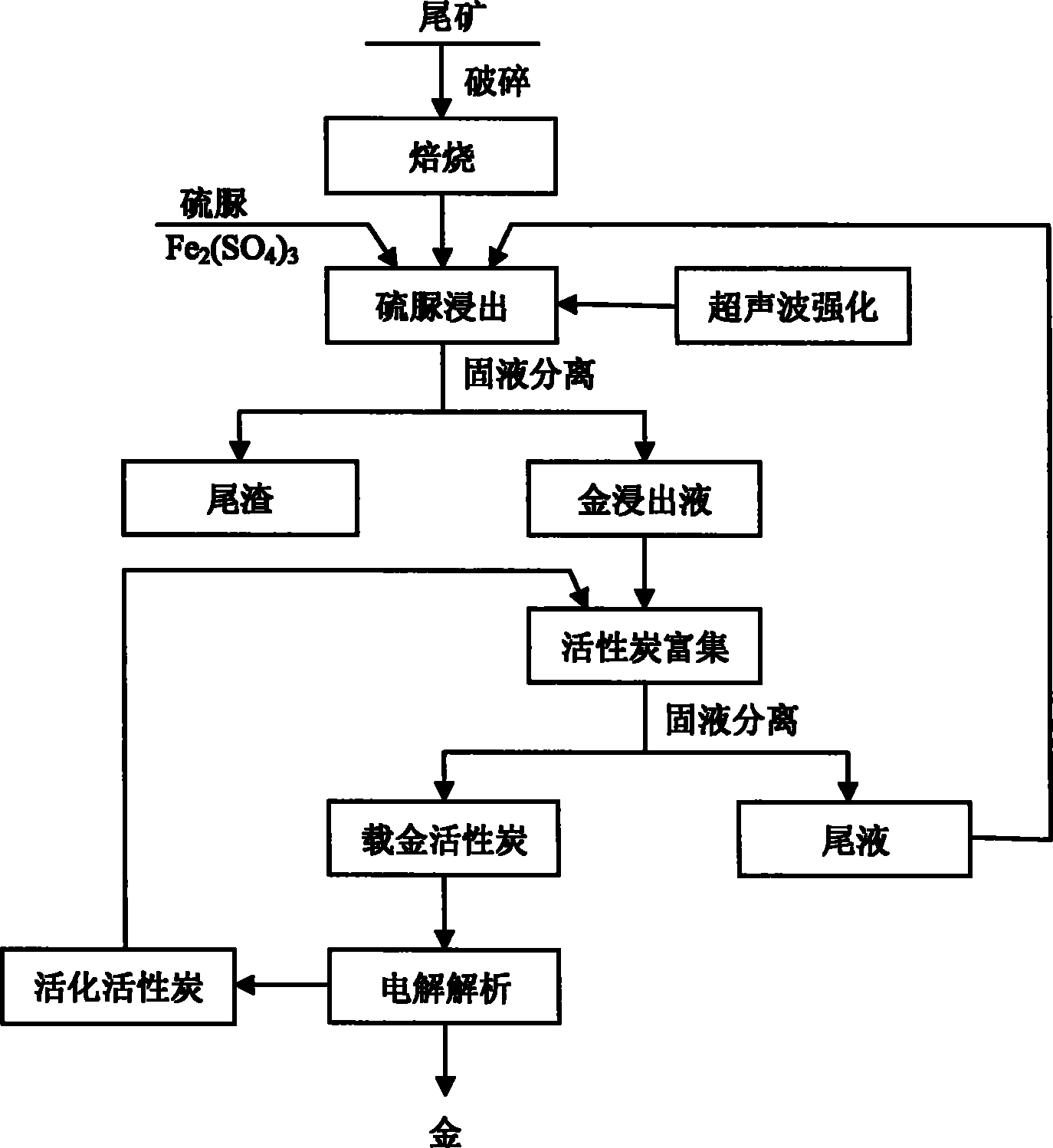

Gold extraction method employing gold cyanided tailing roasting-ultrasonic intensification thiourea gold leaching-activated carbon enrichment

A gold cyanide and activated carbon technology, applied in the field of hydrometallurgy, can solve the problems of cumbersome pretreatment process, unfavorable manual operation, and polluting the production environment, and achieve the effects of shortening the gold leaching time, improving the gold leaching efficiency, and increasing the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The gold cyanide tailings were reground to -100 mesh, 100g was roasted in a muffle furnace at 650°C for 3 hours, cooled, and taken out. Add mass concentration and be 10g / L thiourea solution 200ml (liquid-solid ratio is 2: 1 during leaching), add Fe 2 (SO 4 ) 3 0.6g, make Fe 2 (SO 4 ) 3 The mass concentration is 3g / L, adjust pH=1.5 with sulfuric acid, 90W ultrasonic treatment 30min, stirring and leaching for 0.5 hour, stirring speed is 100rpm, temperature is 293K, after leaching, use suction filter to filter, add 5g activated carbon (tail The mass ratio of ore powder to activated carbon is 20:1), stir evenly, pH=5, stir once every 10 minutes, absorb for 2 hours, the temperature is 293K, use suction filter after enrichment, and the activated carbon is used for analysis and extraction of gold. The extraction rate of gold is 80.5%.

Embodiment 2

[0018] The gold cyanide tailings were reground to -200 mesh, 100g was roasted in a muffle furnace at 1000°C for 2h, cooled, and taken out. Add 300ml of 15g / L thiourea solution (the ratio of liquid to solid during leaching is 3:1), add Fe 2 (SO 4 ) 3 1.2g, make Fe 2 (SO 4 ) 3 The mass concentration is 4g / L, adjusted to pH=3 with sulfuric acid, 100W ultrasonic treatment for 40min, stirring and leaching for 0.6 hour, stirring speed is 120rpm, temperature is 298K, after leaching, use suction filter to filter, add 5g of activated carbon (tail The mass ratio of mineral powder to activated carbon is 20:1), stir evenly, pH=4, stir once every 10 minutes, absorb for 1.5 hours, the temperature is 298K, use suction filter after enrichment, and activated carbon is used for analysis and extraction of gold, The extraction rate of gold is 90.2%.

Embodiment 3

[0020] The gold cyanide tailings were reground to -200 mesh, 100g was roasted in a muffle furnace at 800°C for 2h, cooled, and taken out. Add mass concentration and be 12g / L thiourea solution 300ml (liquid-solid ratio is 3: 1 during leaching), add Fe 2 (SO 4 ) 3 1.2g, make Fe 2 (SO 4 ) 3 The mass concentration is 4g / L, adjusted to pH=2 with sulfuric acid, 110W ultrasonic treatment for 30min, stirring and leaching for 0.5 hour, the stirring speed is 130rpm, and the temperature is 298K. The mass ratio of ore powder to activated carbon is 12.5:1), stir evenly, pH=3, stir once every 10 minutes, absorb for 1.5 hours, the temperature is 298K, use suction filter after enrichment, and the activated carbon is used for analysis and extraction of gold. The extraction rate of gold is 92.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com