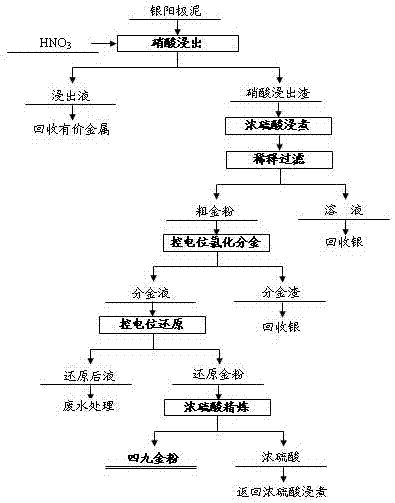

Method for preparing pure gold from silver anode mud through potential control

A silver anode slime and potential technology, applied in the field of hydrometallurgy, can solve the problems of large consumption of reagents, hindering the reaction of dissolving gold, and large investment, and achieve the effects of improving metal recovery rate, eliminating environmental pollution, and stabilizing technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main components of silver anode slime are (%) by weight: Ag25.43, Au14.35, Cu4.87, Bi1.58, Pb0.54 and Sb0.36. Nitric acid is an industrial grade reagent, and its mass percentage concentration is not less than 62.0%; sulfuric acid, hydrochloric acid, hydrogen peroxide, sodium hydroxide and sodium sulfite are all analytical reagents, and the mass percentage concentration of sulfuric acid, hydrochloric acid and hydrogen peroxide is not less than 98.0% respectively , 36.0% and 31.0%, the mass percentages of sodium hydroxide and sodium sulfite are not less than 96.0% and 97.0% respectively.

[0037] Mix silver anode slime, concentrated nitric acid and water at a mass ratio of 1:0.4:1.0, and then heat to a temperature of 92°C for 1.5 hours. The slurry is separated from solid and liquid by vacuum filtration, and the nitric acid leaching residue and concentrated sulfuric acid are mixed at a mass ratio of 1 : 2 to mix, then raise the temperature to 185°C, stir and leach for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com