Process for extracting gold by modified pressure oxidation-cyaniding

A pressure and process technology, applied in the field of gold extraction process of refractory gold-bearing ores, can solve the problems of complex flue gas treatment and dust collection system, long biological oxidation production cycle, no promotion and production application, etc., to avoid secondary The effect of wrapping and leaching rate improvement and avoiding gold loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

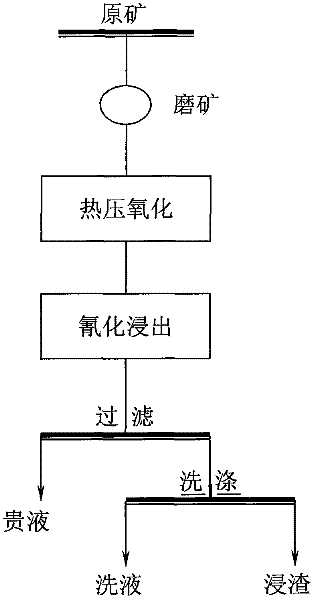

[0054] (1) Grinding and grading operations:

[0055] Grind the refractory raw ore until the particle size is -0.045mm and the content is 85%;

[0056] (2) Alkaline pressure oxidation operation:

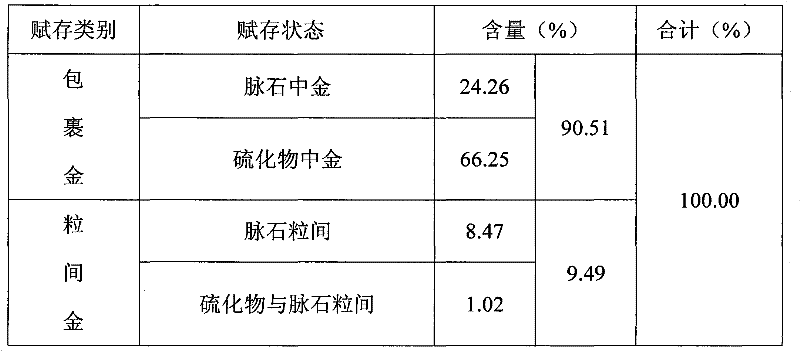

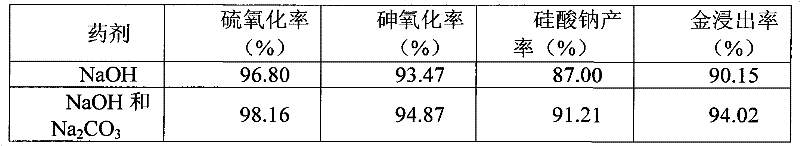

[0057] Adjust the slurry concentration of step (1) to 40%; add NaOH and mixed agent NaOH and NaOH respectively 2 CO 3 , the pH value of the slurry reaches 13, and it is fed into the pressure oxidation system; under the process conditions of ensuring the temperature of 235 ° C, filling 0.4 MPa partial pressure of oxygen, and oxidation time of 90 minutes, the sulfide minerals are fully oxidized, and the silicon dioxide is decomposed. The encased gold is fully exposed and dissociated. The oxidizing liquid is separated from solid and liquid. After the liquid is treated with lime and barium, the clarified liquid is returned to the oxidation system, and the precipitates are recovered separately. After the oxidized slag is thickened, it enters the next step of cyanidation to extract gold;...

Embodiment 2

[0063] (1) Grinding and grading operations:

[0064] Grind the refractory raw ore until the particle size is -0.045mm and the content is 90%;

[0065] (2) Alkaline pressure oxidation operation:

[0066] Adjust the slurry concentration of step (1) to 40%; add single medicament NaOH and mixed medicament NaOH and NaOH 2 CO 3 , the pH value of the slurry reaches 13, and it is fed into the pressure oxidation system; under the conditions of the guaranteed temperature of 235 ° C, 0.4 MPa partial pressure of oxygen, and the oxidation time of 80 minutes, the sulfide minerals are fully oxidized, and the silica is decomposed. Make the wrapped gold fully exposed and dissociated. The oxidizing liquid is separated from solid and liquid. After the liquid is treated with lime and barium, the clarified liquid is returned to the oxidation system, and the precipitates are recovered separately. After the oxidized slag is thickened, it enters the next step of cyanidation to extract gold;

[00...

Embodiment 3

[0072] (1) Grinding and grading operations:

[0073] Grind the refractory raw ore until the particle size is -0.045mm and the content is 95%;

[0074] (2) Alkaline pressure oxidation operation:

[0075] Adjust the slurry concentration of step (1) to 30%; add single agent NaOH and mixed agent NaOH and NaOH 2 CO 3 , the pH value of the pulp reaches 13, and it is fed into the pressure oxidation system; under the conditions of the guaranteed temperature of 180°C, 0.3MPa partial pressure of oxygen, and the oxidation time of 70min, the sulfide minerals are fully oxidized, and the silica is decomposed. Make the wrapped gold fully exposed and dissociated. The oxidizing liquid is separated from solid and liquid. After the liquid is treated with lime and barium, the clarified liquid is returned to the oxidation system, and the precipitates are recovered separately; after the oxidation slag is thickened, it enters the next step of cyanidation to extract gold;

[0076] (3) Cyanide gol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com