Beneficiation method for high-carbon fine particle embedded gold ore

A beneficiation method and fine-grained technology, which is applied in the field of beneficiation of high-carbon fine-grained gold ore, can solve the problems of increased grinding costs, increased management costs, and secondary carbon pollution, so as to improve the recovery rate and save combustion Cost, the effect of removing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A gold mine in Shanyang, Shaanxi Province, X-ray diffraction analysis, the ore is a micro-gold ore of less sulfide carbon-containing peg siliceous slate type, quartz agglomerate (vein) type and breccia type, and a natural type of mixed ore. The metallic minerals in the ore are mainly pyrite and chalcopyrite; the non-metallic minerals are mainly quartz. The ore is characterized by fine gold particle size (<0.01mm); high carbon content, composed of organic carbon and graphitic carbon, with organic carbon content of 3.64% and graphitic carbon of 2.71%.

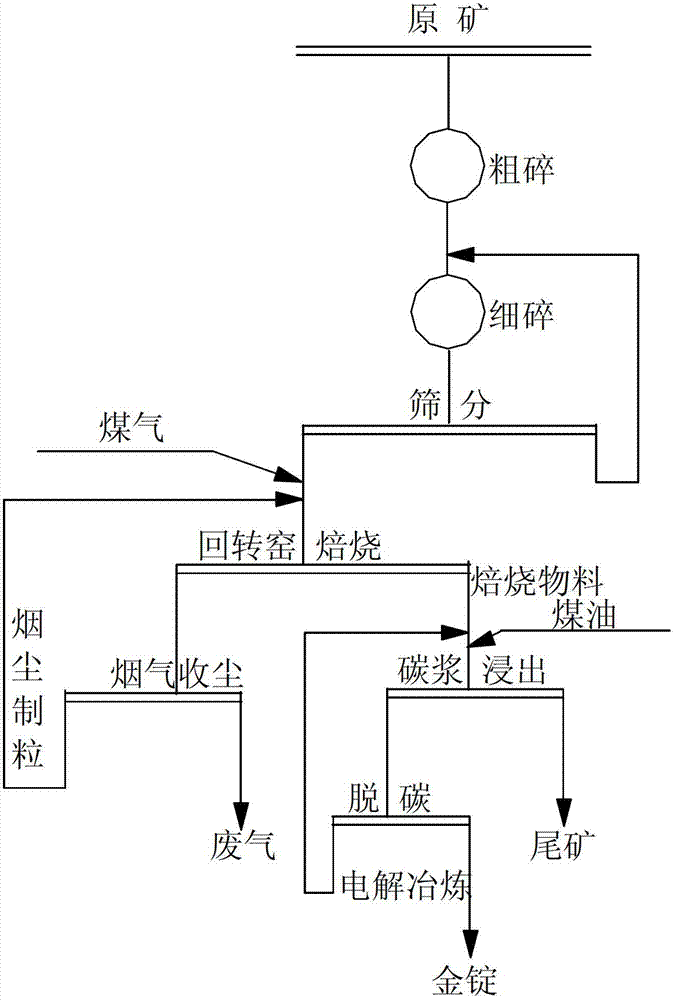

[0020] The mine adopts the process shown in the attached figure, with a daily processing capacity of 200 tons / day of raw ore. The ore is crushed and screened in two stages. After screening, the ore is cached in the sub-ore warehouse and then enters the rotary kiln. The inner diameter of the rotary kiln is 3.6m and the length is 54m. , the inclination angle is 3°, the material filling rate is 12~13%, and the speed is 6min / t...

Embodiment 2

[0026] A gold mine in Luonan County, Shaanxi Province, the ore type is a carbon-containing slate with less sulfide, and the main minerals are pyrite, red limonite, chalcopyrite, etc.; the gangue minerals are mainly quartz, feldspar, Carbonate minerals, graphite, organic carbon and argillaceous minerals have a total carbon content of about 4.5%. The particle size of natural gold is mainly concentrated between 0.002~0.005mm. The gold carrier minerals are minerals such as pyrite and carbonaceous minerals. The carrier and gold have an obvious package relationship, and the gold content in the carbonaceous minerals is about 17%.

[0027] The ore has been carried out in a pilot test (experiment scale: 300kg / time) using the process shown in the attached figure. The ore is crushed and screened. After screening, the ore enters the rotary kiln (Φ300×6200 rotary kiln), and the material filling rate is 12~13%. The rotation speed is 6min / cycle, the inclination angle is 3%, the rotary kiln ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com