Energy-saving optimizing technology for microwave roasting and non-cyanogen gold leaching of sulfur-bearing gold mineral

A technology of microwave roasting and sulfur-containing gold, which is applied in the direction of improving process efficiency, can solve problems such as groping, and achieve the effects of reducing the pressure of environmental protection, shortening pretreatment time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

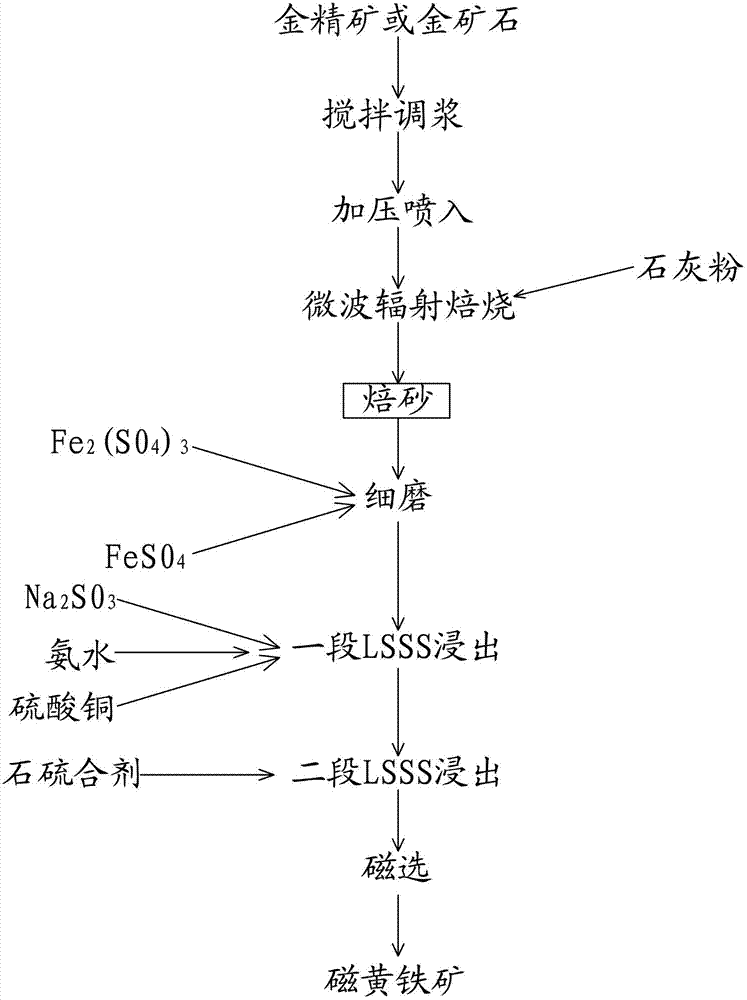

Method used

Image

Examples

Embodiment 1

[0035] The gold mineral of this embodiment is the flotation gold concentrate of quartz and pyrite, and the multi-element analysis table of the gold concentrate is shown in Table 1. The valuable element in the gold concentrate is gold, the metal sulfide minerals are mainly pyrite, and the other minerals are mainly quartz and sericite.

[0036] According to the above analysis results, the gold concentrate of the present embodiment is processed according to the following steps:

[0037] 1) Add 300g of gold concentrate with a particle size of -200 mesh into a mixing tank and stir it with water, and adjust the slurry until the concentration of the mass percentage of the slurry is 70%;

[0038] 2) Pressurize the ore slurry into the reaction chamber of the microwave roasting furnace with a jet machine whose gas source is nitrogen, so that it forms a mist in the reaction room of the microwave roaster, and spray it into the reaction room with a jet machine whose gas source is nitrogen....

Embodiment 2

[0045] The gold mineral of this embodiment is the flotation gold concentrate of quartz and pyrite, and the multi-element analysis table of the gold concentrate is shown in Table 2.

[0046] According to the above analysis results, the gold concentrate of the present embodiment is processed according to the following steps:

[0047] 1) Put 500g of gold concentrate with a particle size of -200 mesh in a mixing tank and add water to stir, and adjust the slurry until the concentration of the mass percentage of the slurry is 60%;

[0048] 2) Pressurize the ore slurry into the reaction chamber of the microwave roasting furnace with a jet machine whose gas source is nitrogen, so that it forms a mist in the reaction room of the microwave roaster, and spray it into the reaction room with a jet machine whose gas source is nitrogen. 15g of lime powder, then roasted by microwave radiation in the reaction chamber, the roasting temperature is 380°C, the microwave power is 3kW, and the roast...

Embodiment 3

[0055] The gold mineral of this embodiment is the flotation gold concentrate of quartz and pyrite, and the multi-element analysis table of the gold concentrate is shown in Table 3.

[0056] According to the above analysis results, the gold concentrate of the present embodiment is processed according to the following steps:

[0057] 1) Add 500g of gold concentrate with a particle size of -200 mesh into a mixing tank and stir it with water, and adjust the slurry until the concentration of the mass percentage of the slurry is 80%;

[0058] 2) Pressurize the ore slurry into the reaction chamber of the microwave roasting furnace with a jet machine whose gas source is nitrogen, so that it forms a mist in the reaction room of the microwave roaster, and spray it into the reaction room with a jet machine whose gas source is nitrogen. 12g of lime powder, then roasted by microwave radiation in the reaction chamber, the roasting temperature is 500°C, the microwave power is 8kW, and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com